Adjustable combined spiral planing tool

A combined and adjustable technology, used in rotary cutting tools, wood processing appliances, manufacturing tools, etc., can solve the problems of large cutting amount, offset of workpiece feed side, high processing cost of planer, and achieve balanced thrust and reduced Wasteful, high flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

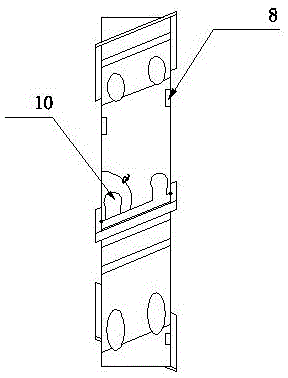

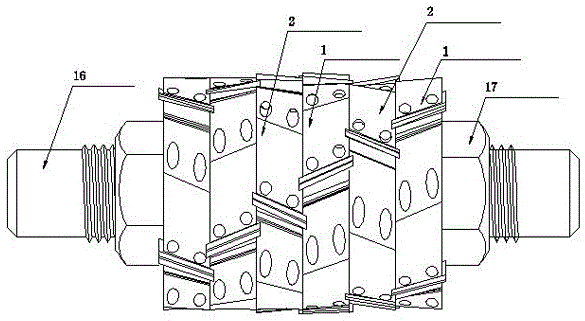

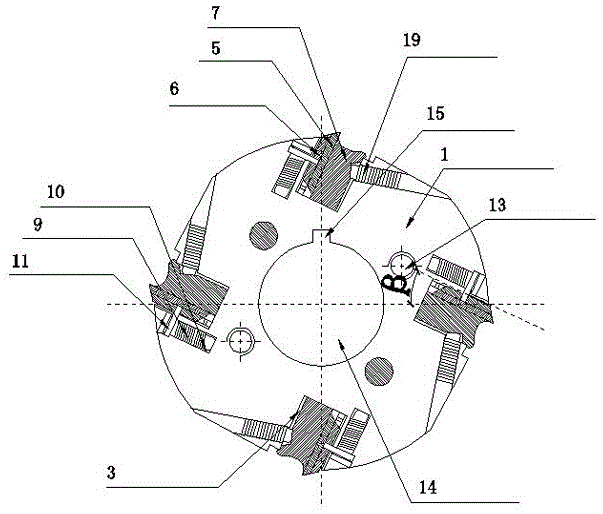

[0020] In order to better understand and implement, the present invention will be further described below with reference to the accompanying drawings: Adjustable combined spiral planer, including planer shaft 16, making 3 left oblique cutter bodies 1 and 3 right oblique cutter bodies 2 respectively , The shape of each cutter body is a circular sheet shape, the thickness of the cutter body is 24mm, the diameter is 120mm, each of the left oblique cutter body 1 and the right oblique cutter body 2 is provided with a planer shaft hole 14 in the left oblique Make 4 left oblique grooves 3 on the cutter body 1, and 4 right oblique grooves 4 on the right oblique cutter body 2. The angle between a positioning surface of each cutter groove and the side of the cutter body 〆 It is 65°, and the included angle β with the central longitudinal section of the cutter body is 25°. The two sides of the cutter body 1 and the cutter body 2 are provided with 4 grooves 8 respectively, and the left obliq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com