Spraying surface defect detector

A detection machine and defect detection technology, which is applied in sorting and other directions, can solve problems such as operator fatigue, missed detection, and difficult to identify spots, and achieve the effects of high automation, reduced labor intensity, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

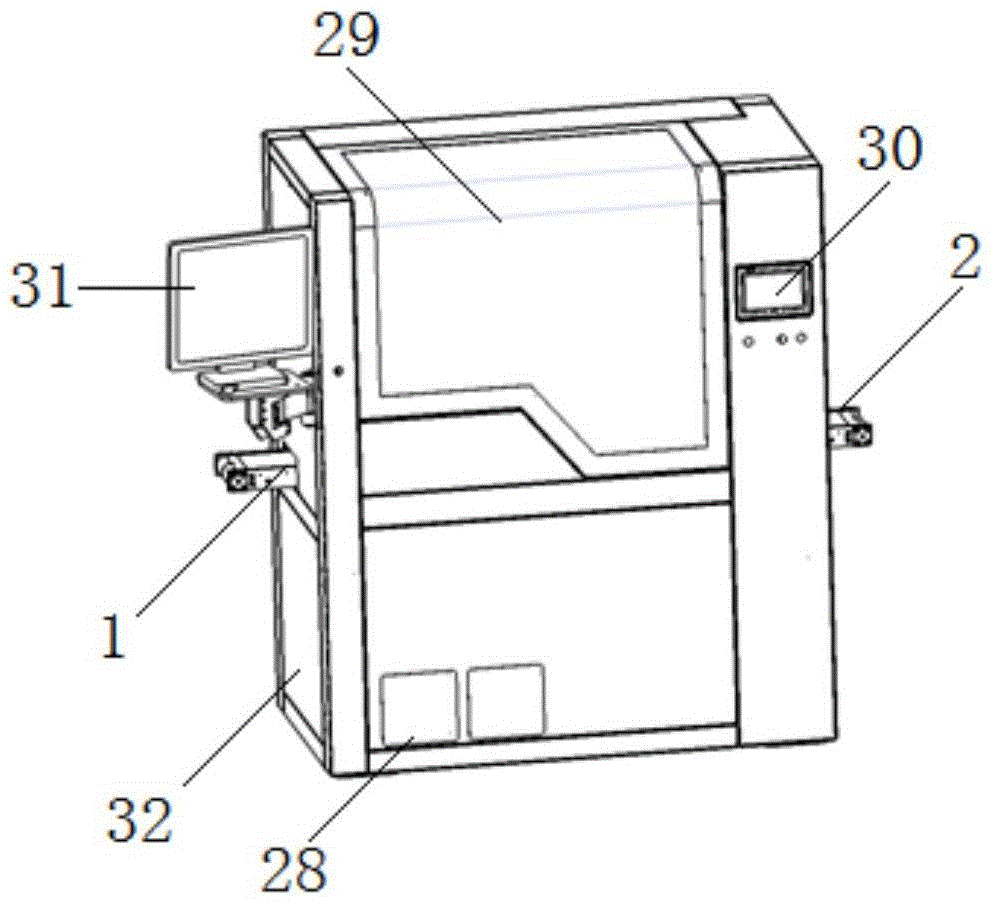

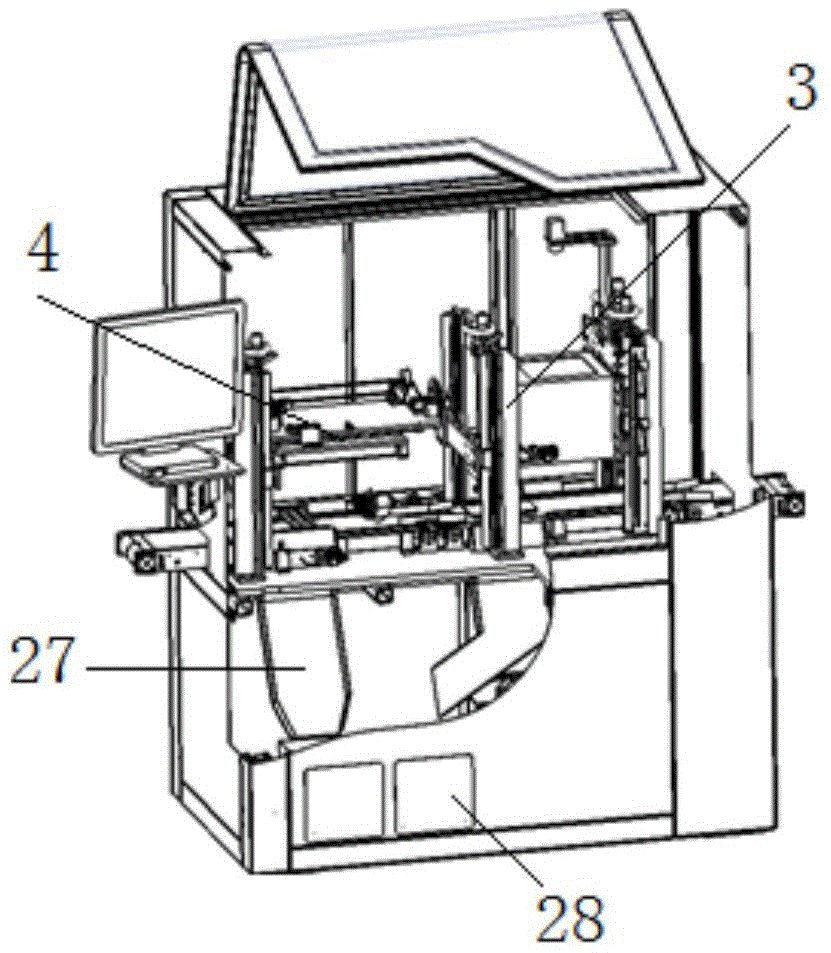

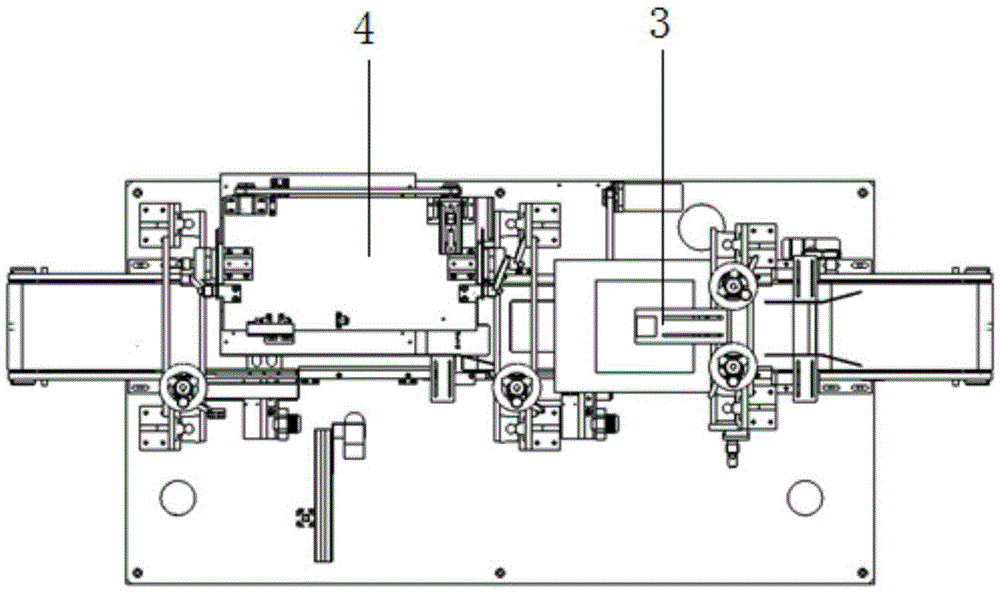

[0031] refer to Figure 1 to Figure 7 , in one embodiment, a spraying surface defect detection machine, including a material inlet 1, a material outlet 2, a feeding mechanism and a first CCD detection module 3 and the second CCD detection module 4, wherein said first CCD detection module 3 is arranged close to said inlet 1 relative to said second CCD detection module 4, said first CCD detection module 3 is used for Carry out CCD coarse inspection to the surface defect of product 25, and reject the defective product with predetermined larger surface defect through detection, described second CCD detection module 4 is used for carrying out CCD micro-inspection to the surface defect of product 25, and Defective products detected with predetermined minor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com