Novel bi-metal active carbon-based desulfurization catalyst

A desulfurization catalyst and activated carbon technology, applied in the field of chemical engineering, can solve the problems of low desulfurization capacity and small sulfur capacity, and achieve the effects of high desulfurization capacity, large working sulfur capacity and high space velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

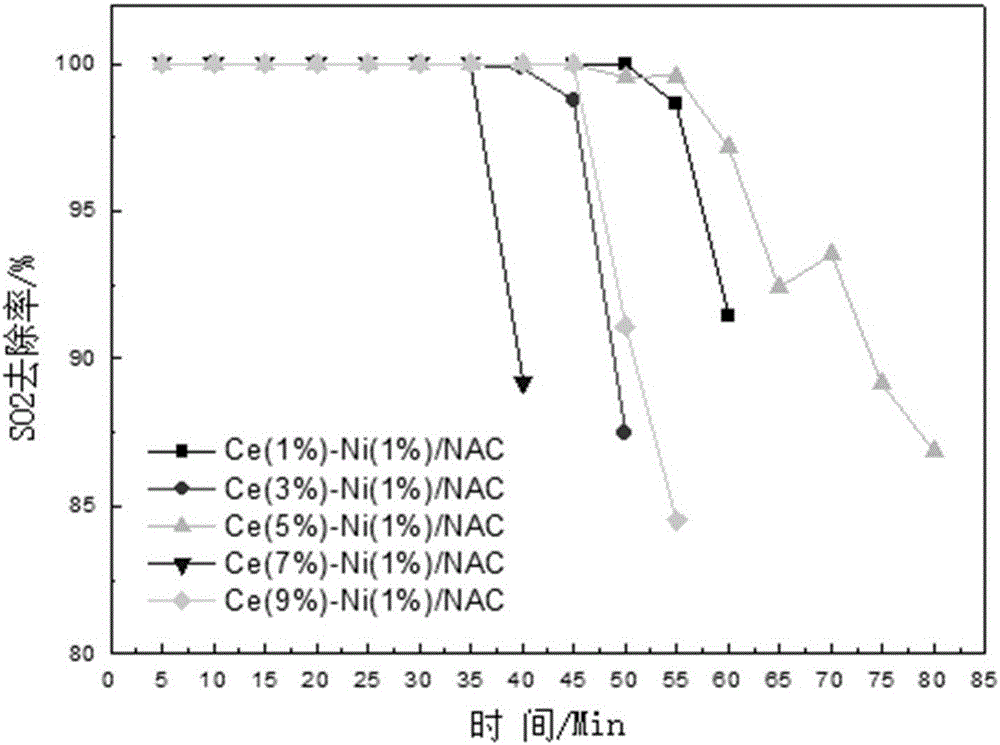

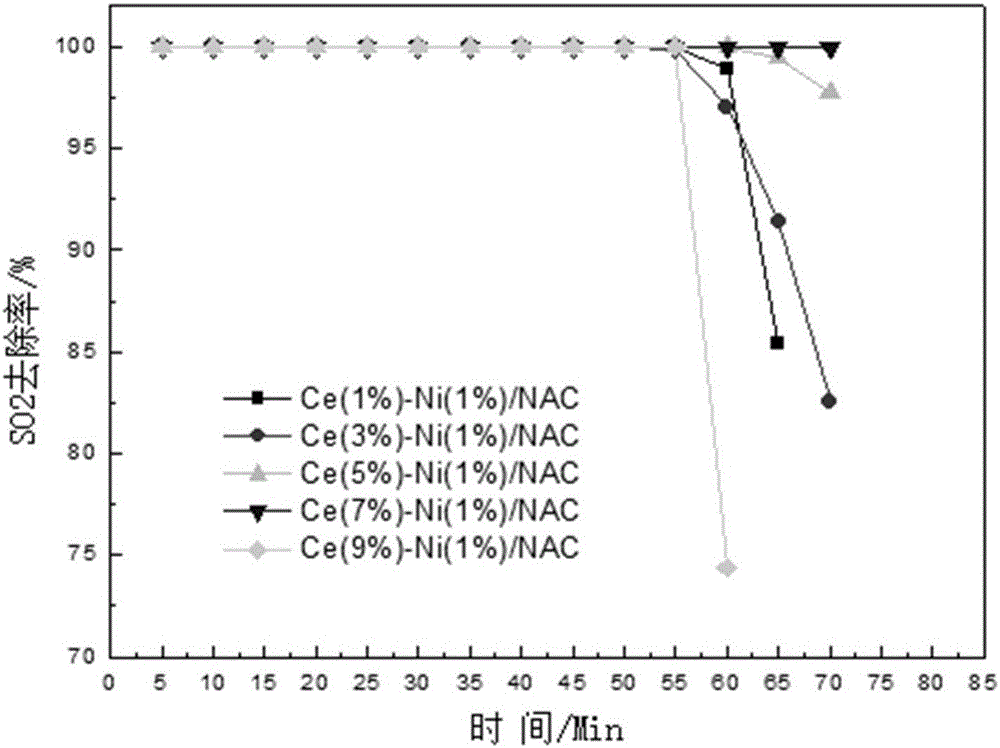

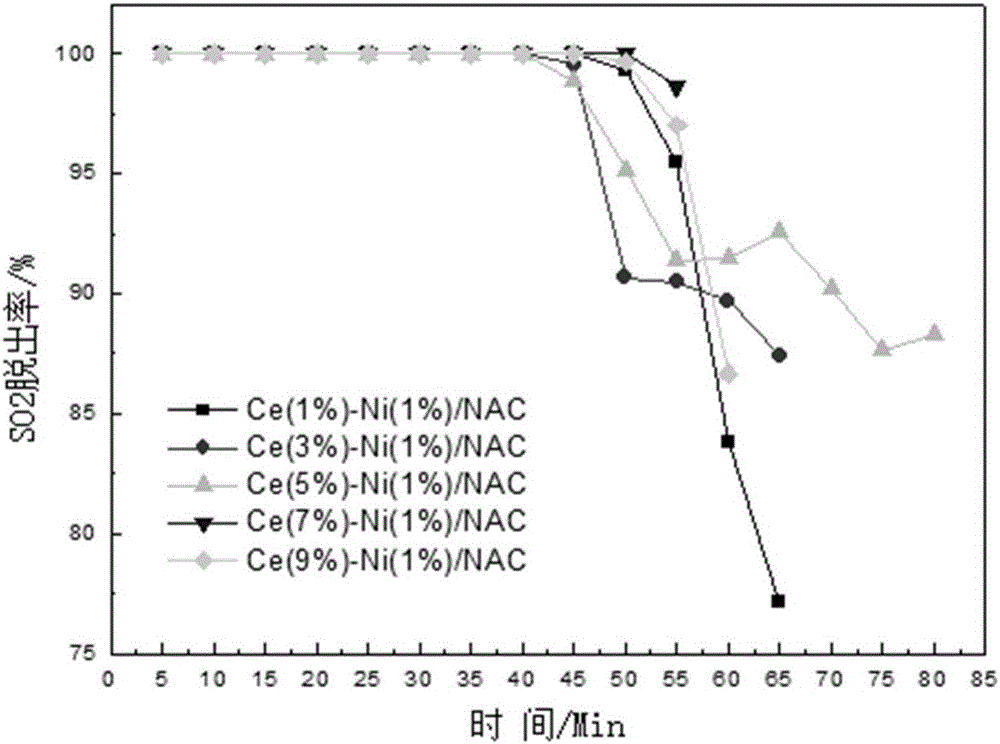

Embodiment 1

[0029] Put activated carbon (AC) in a beaker, add nitric acid with a mass fraction of 40%, stop adding when the nitric acid is just submerged in AC, seal it, heat it in a water bath at 80°C for 1.5h, then cool, and wash with water until the eluate If it is neutral, filter it with suction, and dry it in a drying oven at 110°C for 12 hours to obtain an acid-treated sample, which is designated as NAC. Weigh 20g of NAC, calculate the required mass of cerium nitrate and nickel nitrate according to the loading amount of Ce and Ni and the law of element conservation, and prepare a certain concentration of cerium nitrate solution and nickel nitrate solution. Mix the cerium nitrate solution and nickel nitrate solution and add it to 20g of NAC, make the liquid just wet the NAC, the mass fraction of Ce is 1%, the mass fraction of Ni is 1%, stir, let it stand overnight and put it in a water bath at 70°C Evaporate dry in pot. Finally, place it in a drying oven at 110°C for 12 hours. Afte...

Embodiment 2

[0031] Put activated carbon (AC) in a beaker, add nitric acid with a mass fraction of 40%, stop adding when the nitric acid is just submerged in AC, seal it, heat it in a water bath at 80°C for 1.5h, then cool, and wash with water until the eluate If it is neutral, filter it with suction, and dry it in a drying oven at 110°C for 12 hours to obtain an acid-treated sample, which is designated as NAC. Weigh 20g of NAC, calculate the required mass of cerium nitrate and nickel nitrate according to the loading amount of Ce and Ni and the law of element conservation, and prepare a certain concentration of cerium nitrate solution and nickel nitrate solution. Mix the cerium nitrate solution and the nickel nitrate solution and add it to 20g of NAC, make the liquid just wet the NAC, the mass fraction of Ce is 3%, the mass fraction of Ni is 1%, stir, and put it in a water bath at 70°C after standing overnight Evaporate dry in pot. Finally, place it in a drying oven at 110°C for 12 hours....

Embodiment 3

[0033] Put activated carbon (AC) in a beaker, add nitric acid with a mass fraction of 40%, stop adding when the nitric acid is just submerged in AC, seal it, heat it in a water bath at 80°C for 1.5h, then cool, and wash with water until the eluate If it is neutral, filter it with suction, and dry it in a drying oven at 110°C for 12 hours to obtain an acid-treated sample, which is designated as NAC. Weigh 20g of NAC, calculate the required mass of cerium nitrate and nickel nitrate according to the loading amount of Ce and Ni and the law of element conservation, and prepare a certain concentration of cerium nitrate solution and nickel nitrate solution. Mix cerium nitrate solution and nickel nitrate solution and add to 20g of NAC, make the liquid just wet the NAC, the mass fraction of Ce is 5%, the mass fraction of Ni is 1%, stir, let it stand for one night and put it in a water bath at 70°C Evaporate dry in pot. Finally, place it in a drying oven at 110°C for 12 hours. After d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com