Preparation method and application of metal organic frameworks-mesoporous silica composite material

A metal-organic framework and mesoporous silica technology, applied in the field of material chemistry, can solve the problems of limited application, poor material stability, and difficulty in molding, and achieve the effects of cheap preparation, low cost, and increased adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Take 10g template agent: P123 dissolved in 100g water, add 10g concentrated hydrochloric acid, stir at 40°C for 6h. Then, 10 g of mesitylene was added to the above solution, and stirring was continued for 4 h. Then add 20 g of silicon source: ethyl orthosilicate to the above solution, continue to stir for 5 min and then let stand for 10 h. Finally, 100 mg of ammonium fluoride was dissolved in 10 mL of water and poured into the above solution, aged at 100° C. for 12 h and then dried to obtain silicon oxide.

[0078] The template agent was removed by solvent extraction, that is, 1 g of the above silica was extracted with 20 mL of absolute ethanol in a Soxhlet extractor for 4 h, and the precipitate was obtained by filtration; the above precipitate was dried under vacuum at 50 ° C for 20 h to obtain the desired Mesoporous silica materials.

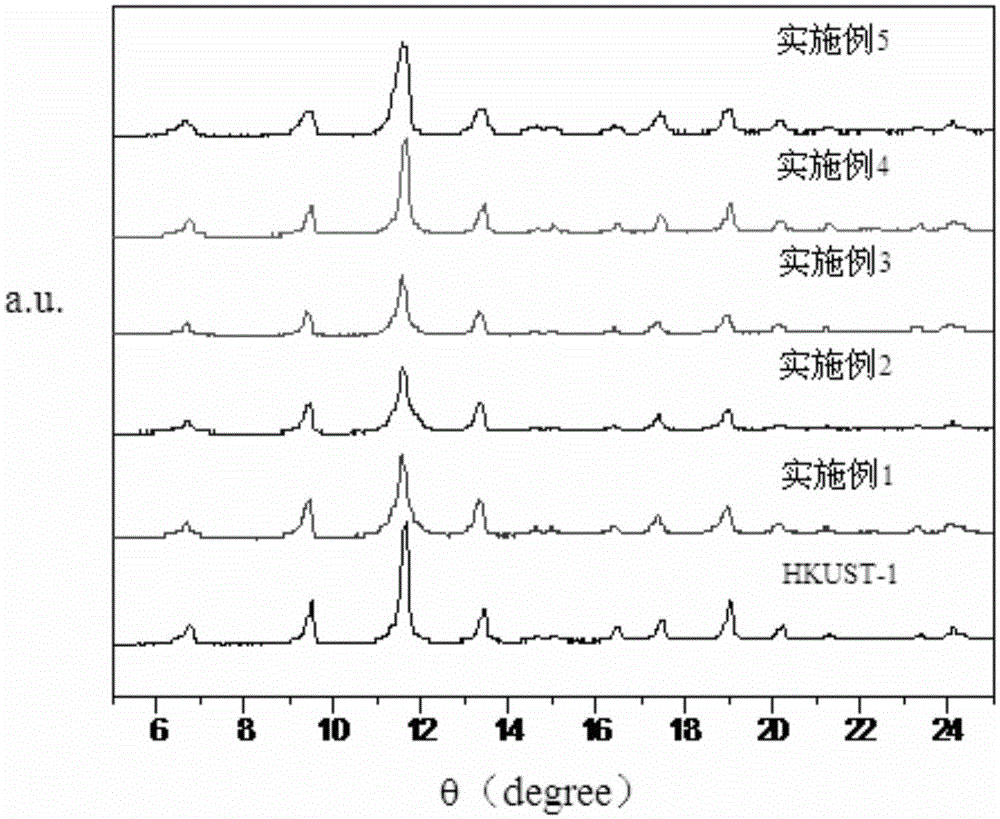

[0079] The metal salt in the metal-organic framework material: 3.2g copper nitrate, the organic ligand: 2.4g trimesic acid were weig...

Embodiment 2

[0081] Take 10g template agent: F127 dissolved in 100g water, add 15g concentrated hydrochloric acid, stir at 60°C for 6h. Then, 10 g of mesitylene was added to the above solution, and stirring was continued for 4 h. Then add 20 g of silicon source: ethyl orthosilicate to the above solution, continue to stir for 5 min and then let stand for 10 h. Finally, 200 mg of ammonium fluoride was dissolved in 10 mL of water and poured into the above solution, aged at 100° C. for 12 h and then dried to obtain silicon oxide.

[0082] The template agent was removed by solvent extraction, that is, 1 g of the above silica was extracted with 20 mL of absolute ethanol in a Soxhlet extractor for 4 h, and the precipitate was obtained by filtration; the above precipitate was dried under vacuum at 50 ° C for 20 h to obtain the desired Mesoporous silica materials.

[0083] The metal salt in the metal-organic framework material: 3.2g of copper nitrate, and the organic ligand: 1.2g of trimesic acid...

Embodiment 3

[0085] Take 10g template agent: P123 dissolved in 100g water, add 10g concentrated hydrochloric acid, stir at 40°C for 6h. Then, 10 g of mesitylene was added to the above solution, and stirring was continued for 4 h. Then add 20 g of silicon source: sodium silicate to the above solution, continue to stir for 5 min and then let stand for 10 h. Finally, 100 mg of ammonium fluoride was dissolved in 10 mL of water and poured into the above solution, aged at 100° C. for 12 h and then dried to obtain silicon oxide.

[0086] The template agent was removed by high-temperature calcination, that is, 1 g of the above-mentioned silicon oxide was roasted for 6 hours at 500° C. in an air atmosphere to obtain the desired mesoporous silicon oxide material.

[0087] The metal salt in the metal-organic framework material: 3.2g copper nitrate, the organic ligand: 2.4g trimesic acid were weighed and dissolved in 25mL N,N-dimethylformamide. Then weigh 0.76g of mesoporous silica material and pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com