Socket module and socket with protective door

A technology of socket module and protective door, which is applied to the parts of the connecting device, electrical components, coupling devices, etc., can solve the problems of unfavorable automatic production and the return spring of the protective door is easy to pop out and fall, so as to facilitate assembly and avoid loose return The effect of playing and preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

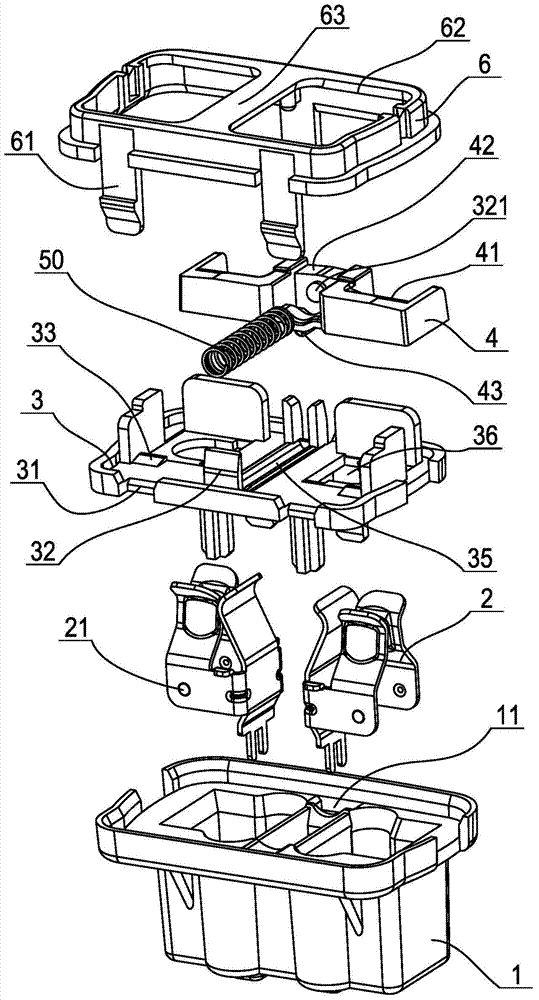

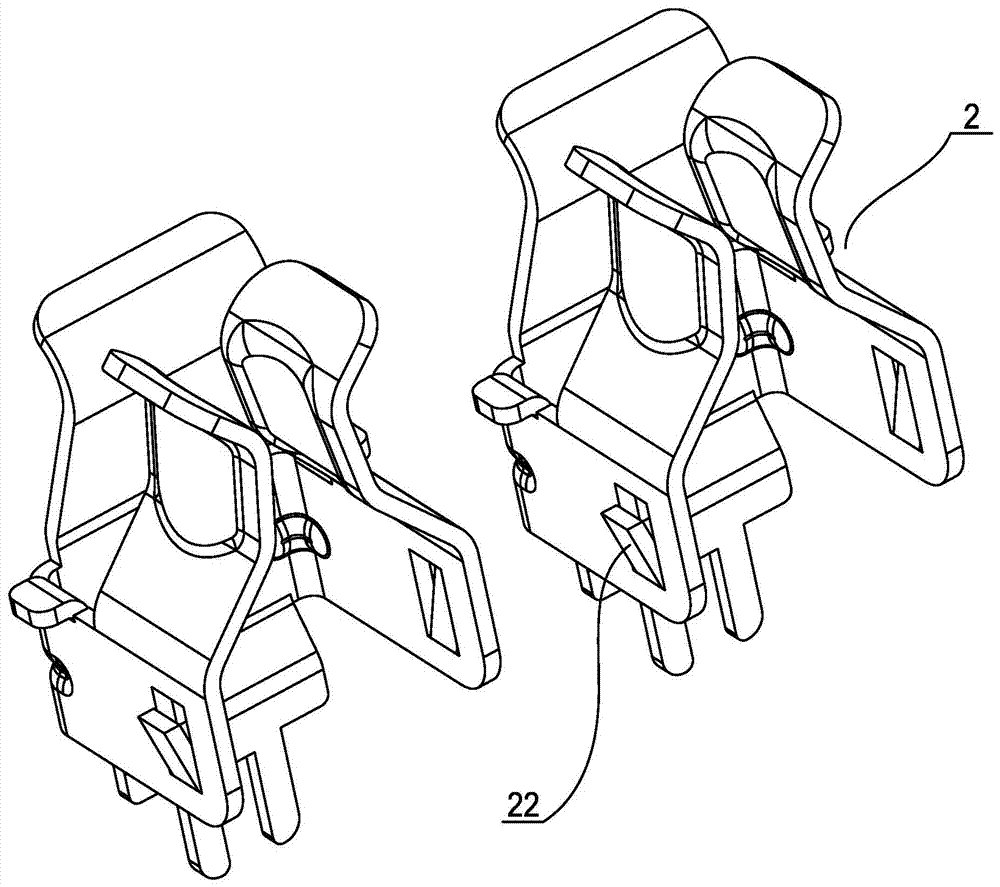

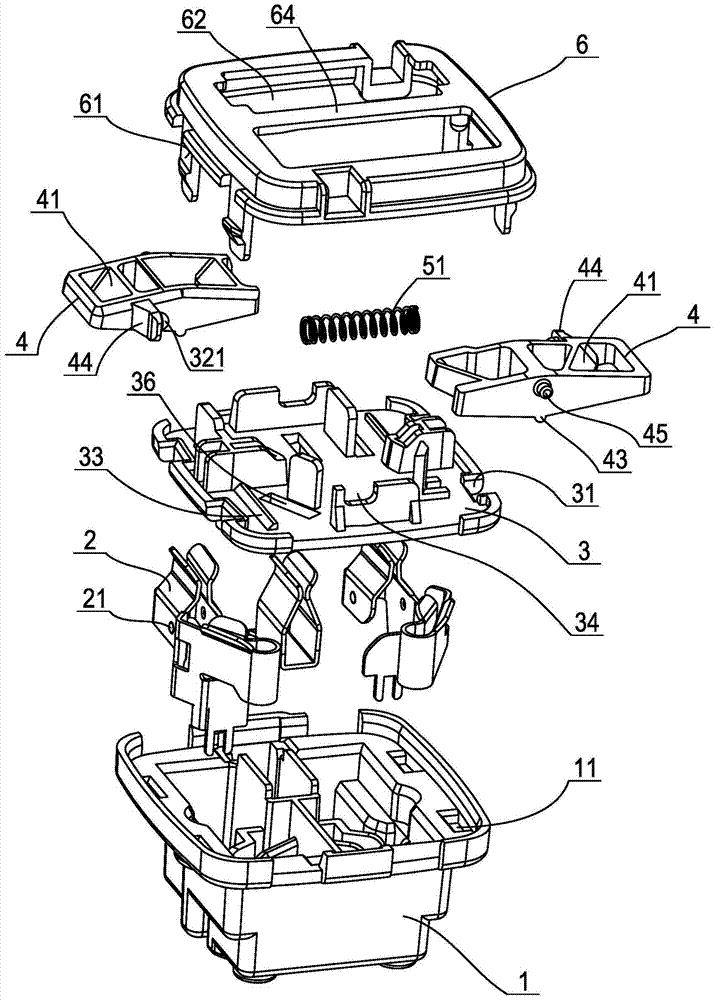

[0035] The utility model relates to a socket module with a protective door, which is suitable for sockets with double-purpose holes, small five-holes, five-flat holes, and small double-row sockets on the panel. like figure 1 As shown, it specifically includes a socket box 1 provided with a socket 2, a pressure plate 3 arranged at the upper opening of the socket box, a protective door 4 arranged on the pressure plate corresponding to the socket, and a reset unit that can drive the protective door to reset . It should be noted that the sockets in the socket box can be set as a dual-purpose hole socket with only one pair of N-pole sockets and L-pole sockets, or a small socket with two pairs of N-pole sockets and L-pole sockets. Five-hole sockets or five-flat hole sockets, or small double-row sockets with three pairs of N-pole sockets and L-pole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com