Megawatt tower type photo-thermal power generation heat collector mounting method and mounting system device

A technology of photothermal power generation and installation method, which is applied in the direction of solar thermal power generation, lifting equipment safety devices, lifting devices, etc., can solve the problems of difficult hoisting and large size of the collector module, and improve installation quality and safety Stability, effect of optimized slip method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

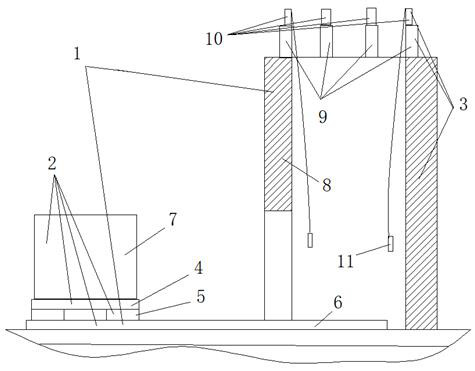

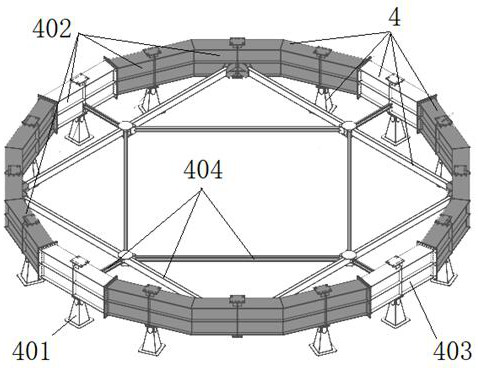

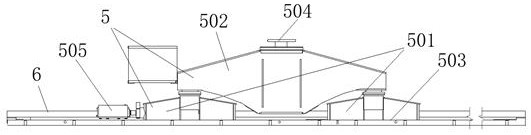

[0042] as attached figure 1 As shown, a 100MW megawatt-level tower-type photothermal power generation collector installation system device, the entire installation system device 1 is composed of two parts; one part is the overall sliding part 2 of the tower-type photothermal power generation collector, and the other part is Tower-type photothermal power generation collector hoisting part 3. The installation of the entire tower-type photothermal power generation collector includes the installation of the collector sliding track, the installation and commissioning of the sliding device, the sliding of the collector, the installation of the temporary platform for the hoisting of the collector, the hoisting door frame of the collector, and the hydraulic lifting device , Installation and commissioning of steel strands, hoisting of heat collectors, removal of temporary measures for hoisting of heat collectors. The overall installation method is to first build a heat absorption towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com