All-fiber current transformer with integrated light path and manufacturing process thereof

A current transformer and manufacturing process technology, applied in voltage/current isolation, instruments, measuring electrical variables, etc., can solve the problems of complex process, low signal-to-noise ratio, and many fusion points of all-fiber current transformers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described below in conjunction with the accompanying drawings.

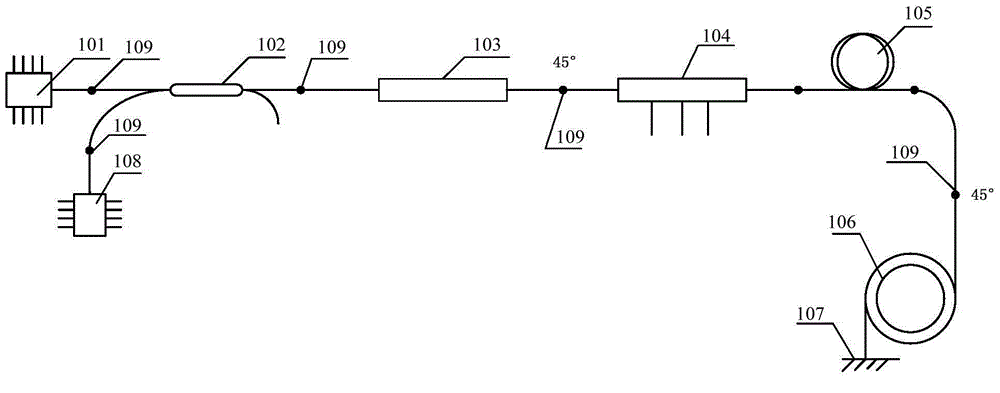

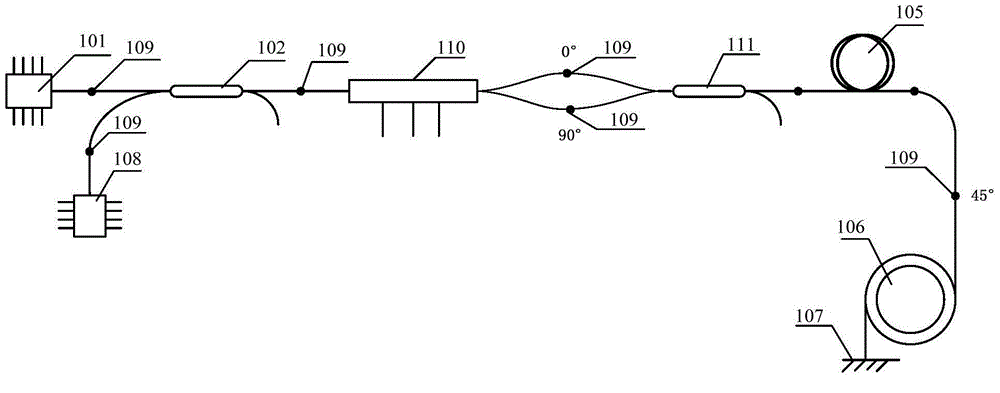

[0044] The invention relates to a manufacturing process of an all-fiber-optic current transformer, aiming at the manufacturing of a FOCT optical circuit, including a photoelectric optical circuit integration process and a modulation optical circuit integration process.

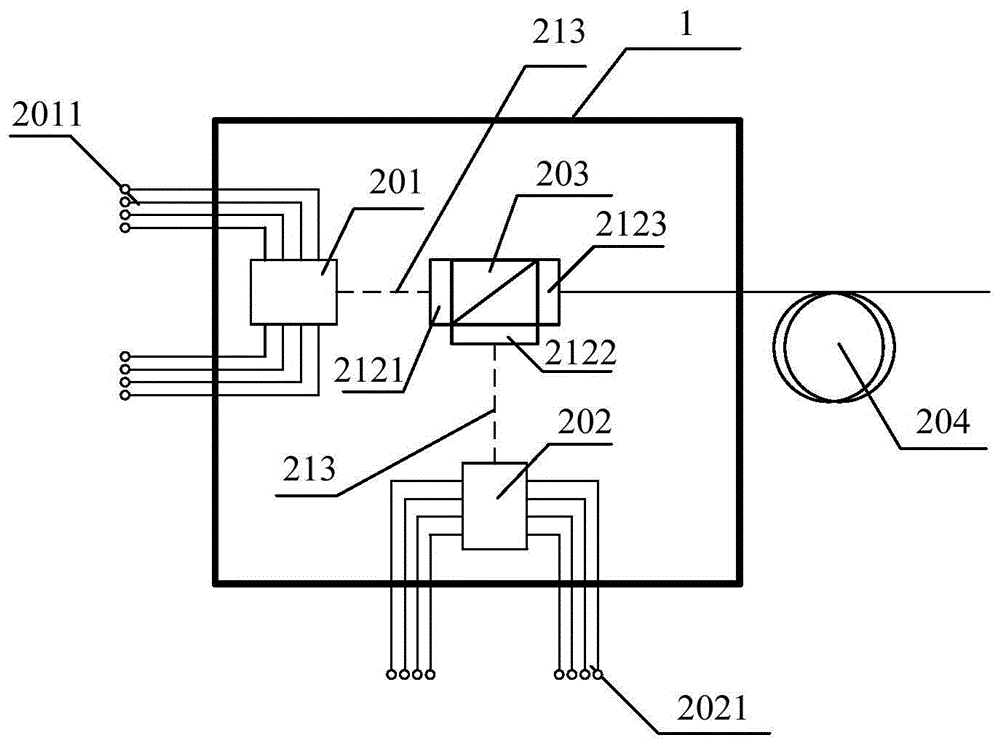

[0045] The photoelectric optical circuit integration process integrates the photoelectric optical circuit. The integrated photoelectric optical circuit realizes the functions of optical devices such as light sources, beam splitters, and photodetectors in the optical path of traditional processes. However, the design principles and production processes are fundamentally different. The optoelectronic and optical circuit integration process applied for adopts a chip-integrated process scheme. Photoelectric optical circuit integration process The principle of integrated photoelectric optical circuit 1 is as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com