Detection device and method for metal steam atomic density of microstructure alkali metal gas chambers

An alkali metal gas chamber and atomic density technology, applied in measuring devices, specific gravity measurement, instruments, etc., can solve problems such as inability to ensure the consistency of each gas chamber unit, inaccurate measurement results, time-consuming optical path modulation, etc., to achieve optical path modulation Save time, improve signal-to-noise ratio, and lower detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

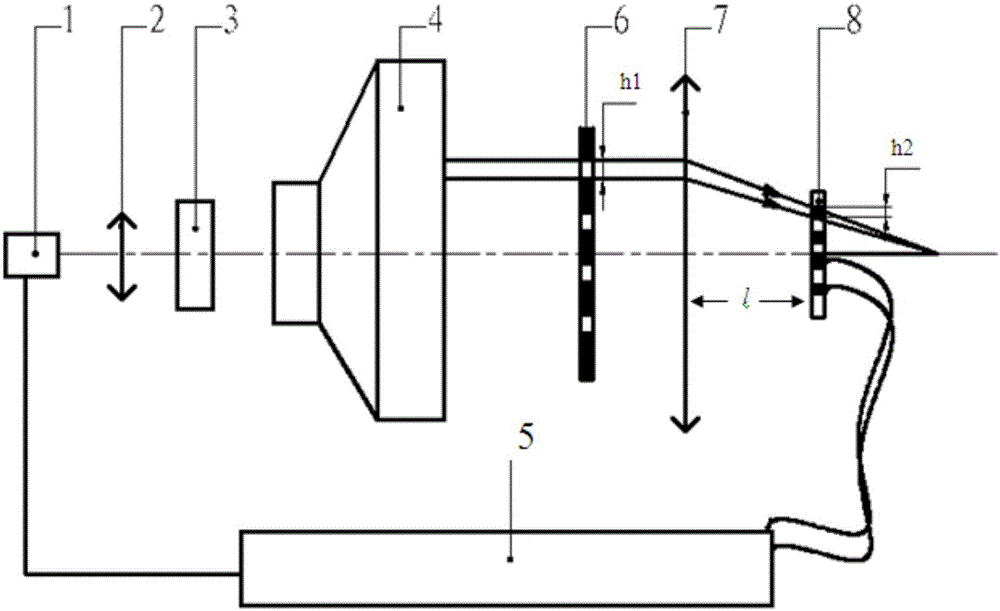

[0027] Specific implementation mode one: refer to figure 1 This embodiment is specifically described. The detection device for the atomic density of alkali metal vapor in the microstructure alkali metal gas chamber described in this embodiment includes a laser 1, a collimation system 2, an attenuator 3, a beam expander 4, and an acquisition signal processing circuit 5 , standard gas chamber assembly 6, convex lens 7 and photoelectric cell array 8,

[0028] The collimation system 2 collimates and transmits the beam emitted by the laser 1 to the attenuator 3, and the attenuator 3 transmits the beam to the beam expander 4, and the beam expander 4 collimates and transmits the beam to the microstructure alkali metal gas cell or the standard gas cell Component 6, microstructure alkali metal gas chamber or standard gas chamber The gas cell unit of component 6 transmits the light beam to the convex lens 7, and the convex lens 7 gathers the light beam to the photocells of the photocell...

specific Embodiment approach 2

[0030] Specific embodiment two: this embodiment is to further illustrate the detection device of the microstructure alkali metal gas chamber alkali metal vapor atomic density described in specific embodiment one, in the present embodiment, the distance between photoelectric cell array 8 and convex lens 7 is l, l=f(1-h 2 / h 1 ), where f is the focal length of convex lens 7, h 2 is the side length of the photocell unit in the photocell array 8, h 1 is the side length of the alkali metal gas cell.

specific Embodiment approach 3

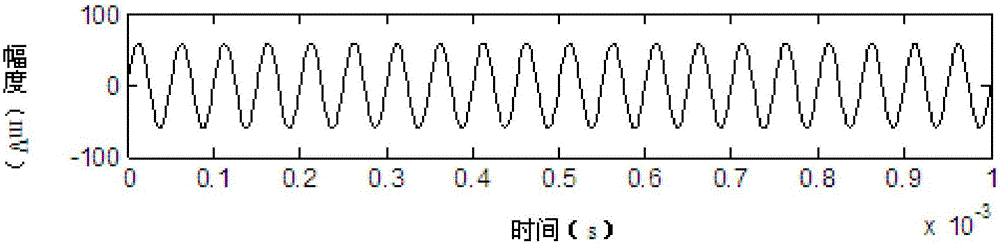

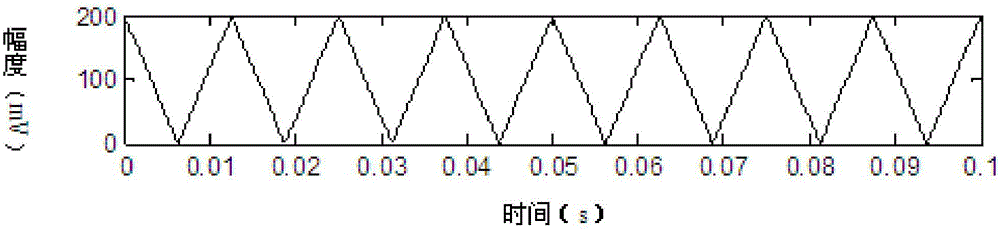

[0031] Specific implementation mode three: refer to Image 6 and Figure 7 This embodiment is described in detail. This embodiment is a further description of the detection device for the atomic density of the alkali metal vapor in the microstructure alkali metal gas chamber described in the first embodiment. In this embodiment, the photoelectric cell array 8 is a The metal gas chamber matches the photocell array.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com