A large-diameter medium-to-high flow rate flowmeter

A high flow rate, large caliber technology, applied to measuring devices, instruments, etc., can solve problems such as large pressure loss, energy waste, and decreased measurement accuracy, and achieve the effects of reducing pressure loss, improving measurement accuracy, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

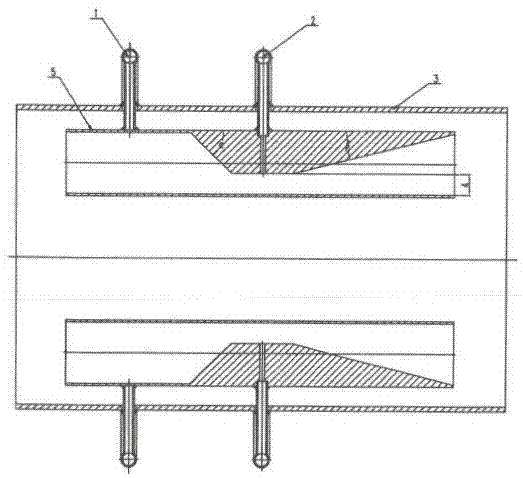

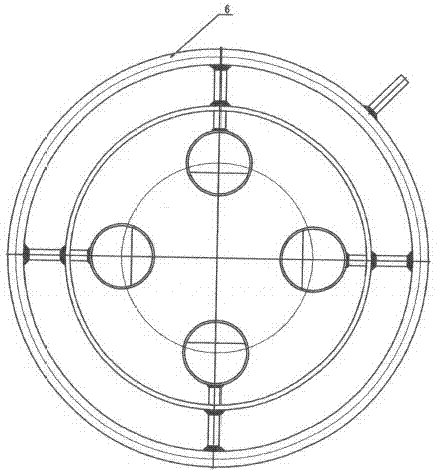

[0014] A kind of medium and high velocity flowmeter of large diameter, it comprises measuring pipeline 3, such as figure 1 and 2 As shown: four rectangular tube generators 5 are arranged in the measuring pipeline 3, and each rectangular tube generator 5 is provided with a positive pressure-taking tube 1 and a negative pressure-taking tube 2, and the positive pressure-taking tubes of the four rectangular tube generators 5 The pipe 1 and the negative pressure-taking pipe 2 are connected through a round pipe 6 .

[0015] The pipe centers of the four rectangular pipe generators 5 are evenly arranged on the iso-annulus of the measuring pipe 5 .

[0016] In the rectangular tube generator 5, α is 45°, β is 14°, and the wedge height H is 0.4D, where D is the inner diameter of the measuring pipe 3. α is the contraction angle of the wedge, β is the divergence angle of the wedge, and H is the height of the wedge, that is, the height of the wedge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com