Cooling tower vapor condensation recovery device utilizing industrial low-temperature exhaust heat for refrigeration

A technology of condensation recovery and low-temperature waste heat, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of large evaporation loss of cooling towers, difficulty in effective recovery, and difficulty in recycling, etc., to extend the service life, good Energy saving and environmental protection benefits, the effect of efficiency guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail through the embodiments below in conjunction with the accompanying drawings.

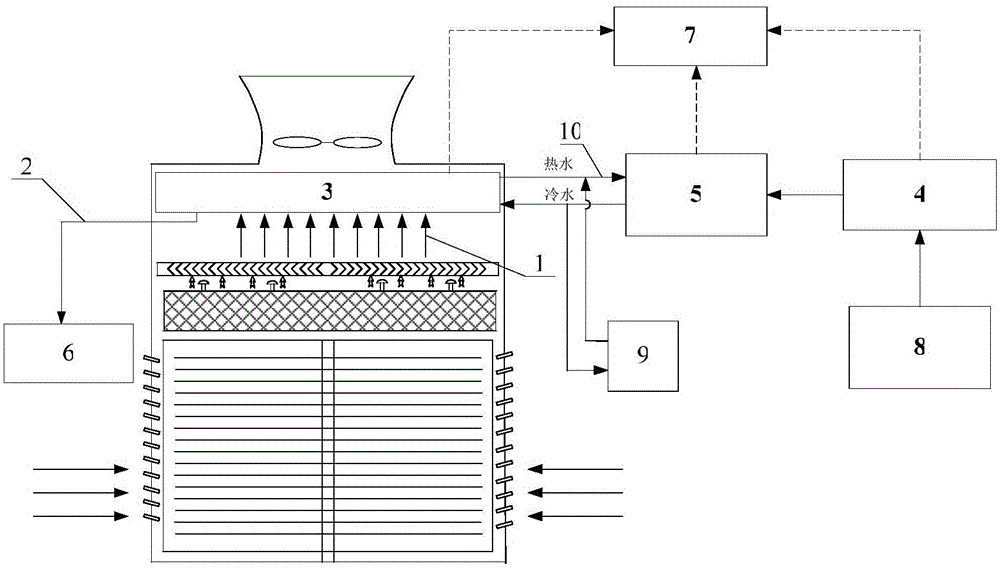

[0028] like figure 1 Shown is a system according to an embodiment of the present invention that uses industrial low-temperature waste heat to refrigerate and recover cooling tower exhaust water, wherein an evaporator (3) is arranged above the exhaust device (1) at the top of the cooling tower, and the cooling tower exhaust The water contained in the gas device (1) is deeply recovered; the condensed water flows into the pure water collector (6) through the condensed water diversion channel (2); the working fluid in the heat exchange surface of the evaporator (3) is cold water, and the The refrigeration unit (5) provides, and the hot water produced by heat exchange flows back to the refrigeration unit (5) for recycling.

[0029] According to an embodiment of the present invention, the refrigerating unit (5) can adopt ammonia water absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com