Stepless speed regulating control system of pneumatic monorail crane

A stepless speed regulation and control system technology, applied in the field of monorail cranes, can solve the problems of unstable operation of the main engine of monorail cranes, easy impacts caused by monorail cranes and hoisting parts, increased wear of friction wheels, etc., to avoid fast start and stop Phenomenon, improvement of reliability and safety, effect of shock reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

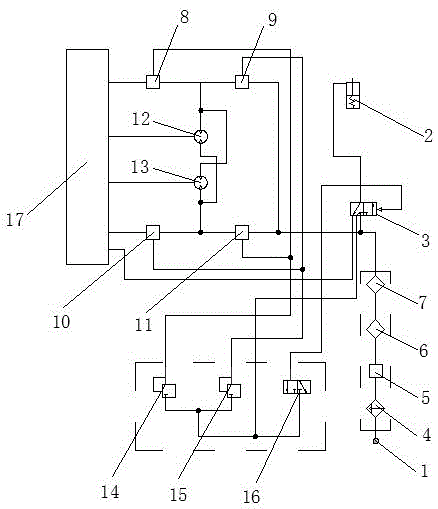

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] Such as figure 1 As shown, a pneumatic monorail crane stepless speed regulation control system includes an air source 1, a cylinder 2, and a main control reversing valve 3. The output pipeline of the air source 1 is divided into two routes, one of which passes through the main control reversing valve The air inlet of valve 3 communicates with cylinder 2, and the other way communicates with the air inlets of speed regulating valve B9 and speed regulating valve D11 respectively;

[0014] There are two branches at the exhaust port of the speed regulating valve B9, one branch communicates with the air inlet of the speed regulating valve A8, and the other branch communicates with the first working port of the motor A12 and the first working port of the motor B13 respectively. The working port is connected, and the exhaust port of the speed regulating valve D11 has two br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com