Drill rig support frame for coal mine

A technology for drilling rigs and coal mines, applied in drilling equipment, earthwork drilling, support devices, etc., can solve the problems of large space occupation, inflexible adjustment of pitch angle, and inability to be used independently, saving space and avoiding rod change interference , the effect of improving positional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

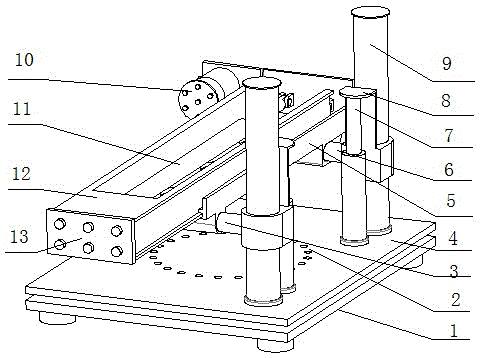

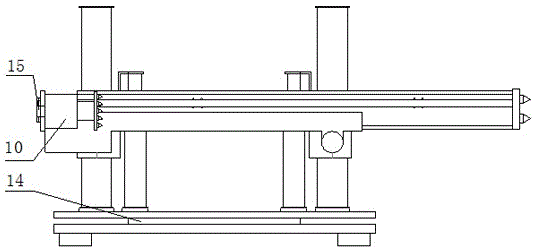

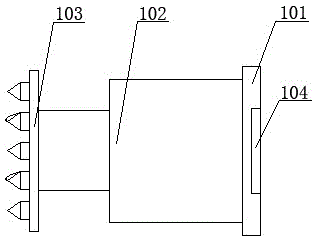

[0016] As shown in the figure, a coal mine drilling rig support includes a chassis 1, a turntable bearing 14 and a support body, the support body is arranged on the base 1 through the turntable bearing 14, and the support body includes a The rotating platform 4, the corresponding positions of the rotating platform 4 and the base 1 are provided with positioning holes 2, and the upper end surface of the rotating platform 4 is provided with two guide support columns 9, and each guide support column 9 is provided with a pipe buckle 8, in which The pipe buckle 8 on one side is provided with front beam 3, and the pipe buckle 8 on the other side is provided with back beam 6, and described front beam 3 and back beam 6 are fixedly connected with corresponding pipe buckle 8 respectively, between front beam 3 and The back beam 6 is provided with a slide seat 5 for placing the guide rail 12. The front beam 3 passes through the holes on the two side walls of the slide seat 5 and is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com