High-backfill deformation wireless remote integrated monitoring system and mounting and monitoring method

A comprehensive monitoring and high fill technology, applied in infrastructure engineering, on-site foundation soil survey, construction, etc., can solve the problems of frequent accidents, inability to achieve real-time monitoring, blindness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

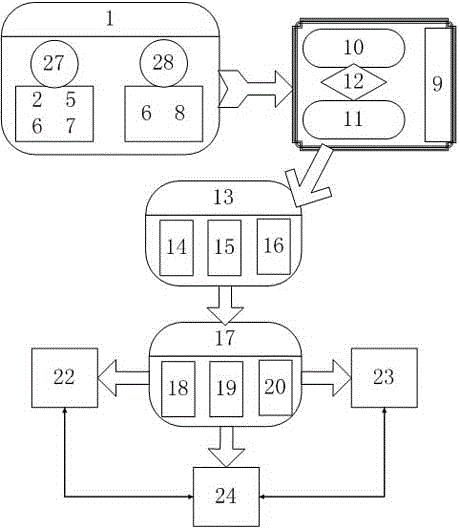

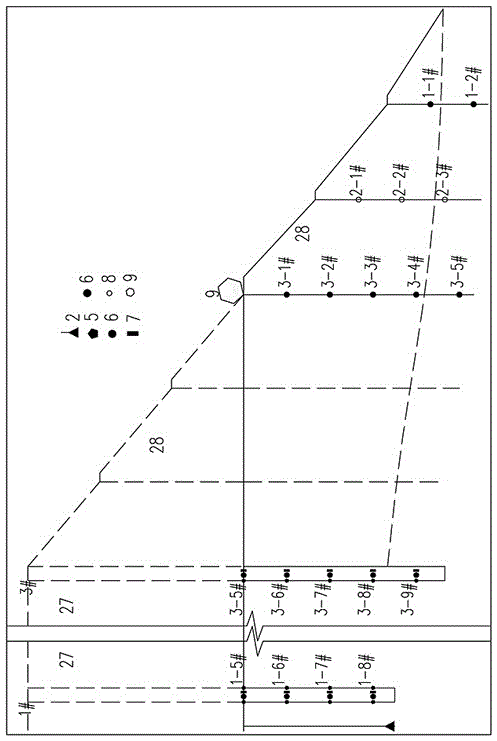

[0075] The present invention is a wireless remote comprehensive monitoring system for high filling deformation and an installation monitoring method. The wireless remote comprehensive monitoring system for high filling deformation is composed of a sensor system 1, a data acquisition system 9, a wireless transmission system 13 and a data management and analysis system 17. A variety of information during and after filling construction can be collected and stored through the sensor system 1 and the data acquisition system 9, and the data signal is transmitted to the data management and analysis system 17 of the monitoring unit's online computer 21 through the wireless transmission system 13;

[0076] The sensor system 1 includes a single-point settlement meter 2 for monitoring the total settlement and layered settlement of the high-fill foundation 27 , an earth pressure cell 5 for monitoring the earth pressure of different high-fill soil layers for the high-fill foundation 27 , and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com