Following cathode device with distance between following cathode device and active anode kept unchanged and application of following cathode device

An active anode technology that remains unchanged, applied in the field of electrochemical electrolysis, can solve the problem of loss of effective area of the cathode plate, and achieve the effects of no loss of effective area, easy installation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

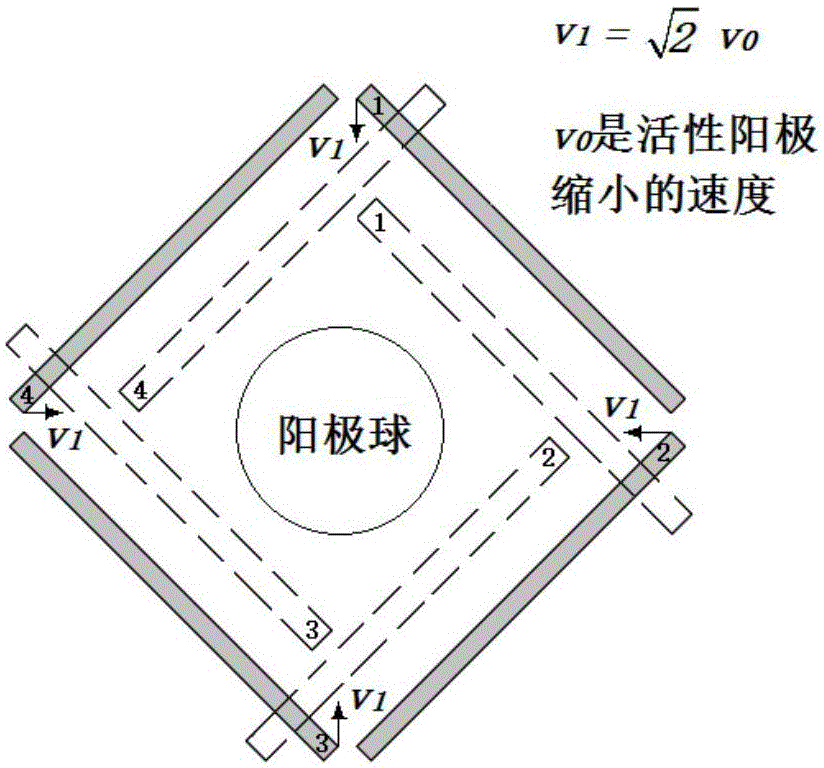

[0018] This embodiment is a follower cathode device of the present invention that keeps the constant distance from the active anode, and is used in the electrolysis process containing a spherical active anode under radioactive conditions. The handles of the 4 special-shaped plates are clamped, and the 4 special-shaped plates are arranged according to the four sides of the circumscribed square of the active anode of the spherical fuel element to realize mechanical installation; the wire connected to the negative pole of the electrolyzer power supply passes through the 4 special-shaped plates in the form of screws and nuts The through hole on the handle is clamped to realize electrical connection; during electrolysis, the mechanical device of the electrolytic cell drives 4 special-shaped plates to move along the diagonal of the square to the center of the square, and the moving speed is equal to the shrinking speed of the active anode times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com