Method for preparing coal water slurry

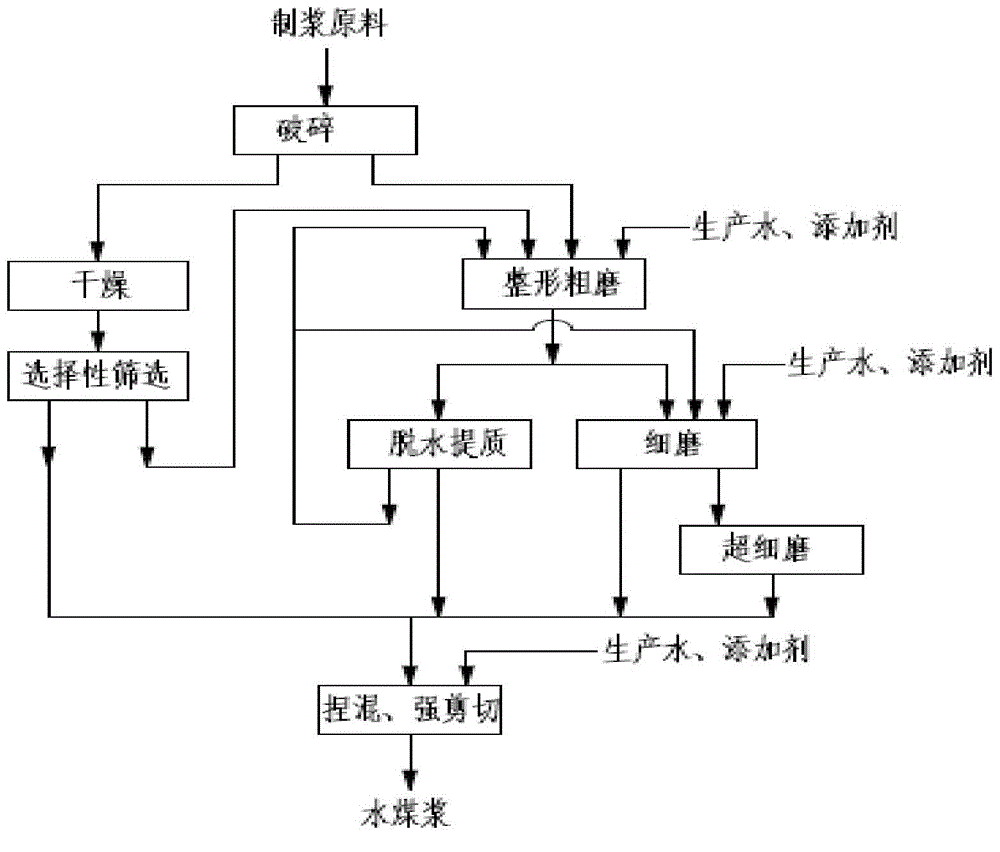

A coal-water slurry and slurry technology, which is used in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of irregular particle size of raw coal particles at all levels, difficult-to-pulverize coal slurry effect, and inhomogeneity, etc. To achieve the effect of convenient parameter adjustment, wide range of coal adaptation, and increased concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing coal-water slurry from Mengdong lignite, said Mengdong lignite is Dongming Coal Mine lignite in Hailaer, Inner Mongolia, the analysis water is 14.8%, the total water is 32%, the ash content is 12.4%, and the particle size is less than 50mm; The method includes the following steps:

[0041] (1) crushing the Mengdong lignite to below 13mm to obtain the first slurry;

[0042] (2) Mix 75wt% of the first slurry with production water in a mass ratio of 3.5:2, then add 0.2wt% sodium humate to obtain the second slurry; dry the remaining first slurry, and carry out selective screening points to obtain the eighth slurry with a particle size of 150-1000 μm;

[0043] (3) Shaping, stirring and grinding the second slurry to spherical particles at 19° C. at a stirring and grinding speed of 20 m / s to obtain the third slurry. The solid content of the third slurry is 35%, and the largest particle Less than 2.4mm, D38 is 75μm;

[0044] (4) Dehydrate and upgrade 8...

Embodiment 2

[0049]A method for preparing coal-water slurry from coal in the Wucaiwan coal mine in the Junggar area of Xinjiang, the coal in the Junggar area of Xinjiang has an analysis water of 11.3%, a total water of 18.6%, an ash content of 13.1%, and a particle size of less than 50mm; the method Including the following steps:

[0050] (1) crushing the coal in the Junggar region of Xinjiang to below 13 mm to obtain the first slurry;

[0051] (2) Mix 85wt% of the first slurry with production water in a mass ratio of 3.8:2, then add 0.1wt% lignosulfonate to obtain the second slurry; dry the remaining first slurry, and select sieving to obtain the eighth slurry with a particle size of 150-1000 μm;

[0052] (3) Shaping, stirring and grinding the second slurry to spherical particles at 22° C. at a stirring and grinding speed of 20 m / s to obtain the third slurry. The solid content of the third slurry is 40%, and the largest particle Less than 2.4mm, D38 is 75μm;

[0053] (4) 84wt% of t...

Embodiment 3

[0058] A method for preparing coal-water slurry from coal in the Ordos Shenfu area of Inner Mongolia, the coal in the Ordos Shenfu area of Inner Mongolia has an analysis water of 5.7%, a total water of 13.6%, ash content of 6.9%, and a particle size of less than 50mm; the method Including the following steps:

[0059] (1) crushing the coal in the Shenfu area of Ordos, Inner Mongolia to less than 13 mm to obtain the first slurry;

[0060] (2) Mix 80wt% of the first slurry with production water in a mass ratio of 4:2, then add 0.1wt% lignosulfonate to obtain the second slurry; dry the remaining first slurry, and select sieving to obtain the eighth slurry with a particle size of 150-1000 μm;

[0061] (3) Shaping, stirring and grinding the second slurry to spherical particles at 22°C and at a stirring and grinding speed of 20m / s to obtain the third slurry, the solid content of the third slurry is 44%, the largest particle Less than 2.4mm, D40 is 75μm;

[0062] (4) Dehydra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com