Preparation method of carbon nano tube (CNT)/polylactic acid (PLA) electromagnetic shielding composite material with isolation structure

A composite material and electromagnetic shielding technology, which is applied in the field of preparation of carbon nanotube/polylactic acid isolation structure conductive polymer composite materials, can solve many problems, and achieve the effect of high conductivity, wide sources and excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

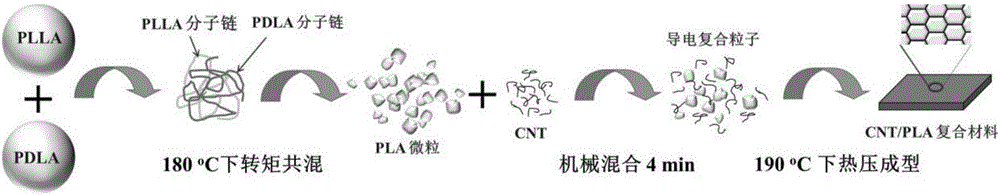

[0034] The process steps adopt:

[0035] (1) Drying of raw materials: Dry CNT in an oven at 80°C until the moisture content is lower than 0.01%; dry PDLA and PLLA in a vacuum oven at 60°C for more than 24h until the moisture content is lower than 0.01%.

[0036] (2) Preparation of PLA microparticles: PDLA and PLLA were added to a Haake torque rheometer, and mixed at 40 rpm and 180° C. for 10 min to obtain PLA microparticles.

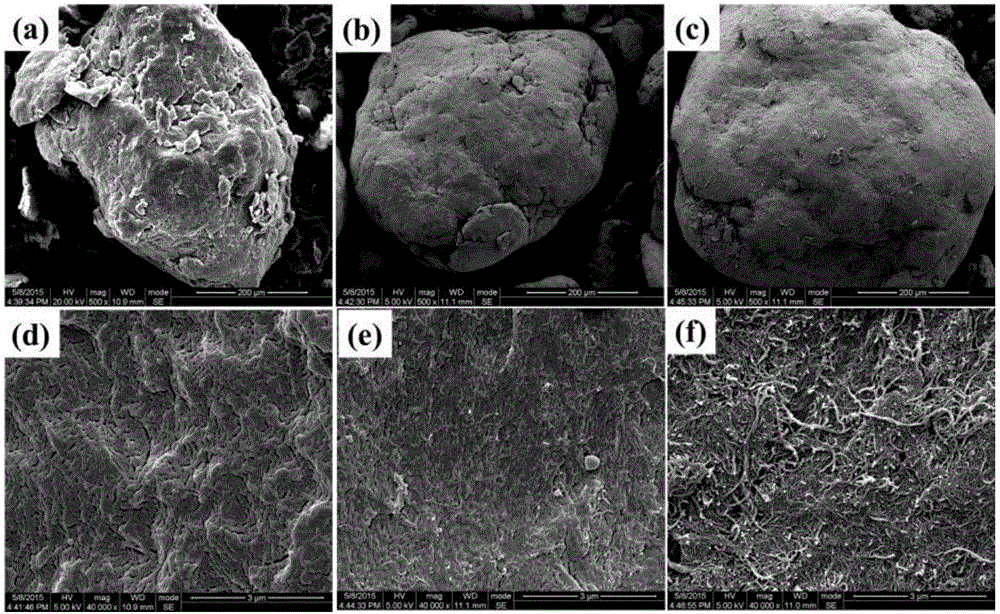

[0037] (3) Preparation of conductive composite particles: Weigh the PLA particles obtained in (2) and dry CNTs in (1) according to a certain mass ratio (see Figure 8 ) placed in a high-speed mixer, mixed for 3 minutes at a stirring speed of 24,000 rpm, and kept at a temperature not exceeding 60° C. during the mixing process to achieve uniform coating of PLA particles by CNTs.

[0038] (4) Compression molding: Preheat the composite material particles mixed in (3) at a temperature of 190-220°C for 10 minutes, then hot-press at 10MPa for 5 minutes, and fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com