Preparation method and application of soft-base curing component material

A technology of polypropylene composition and hindered amine light stabilizer, which is applied in the field of preparation of soft-base curing treatment component materials, can solve the problem of not considering the synergistic effect of light stabilizer, short weather resistance, light stabilizer and antioxidant being easily damaged. damage and other problems, to avoid changes in mechanical properties and color, high anti-oxidation ability, and solve the effects of thermo-oxidative aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

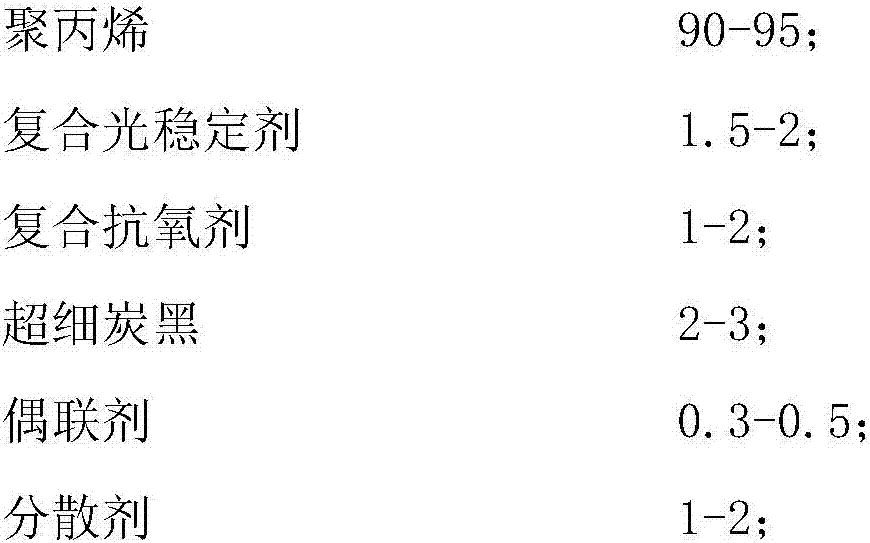

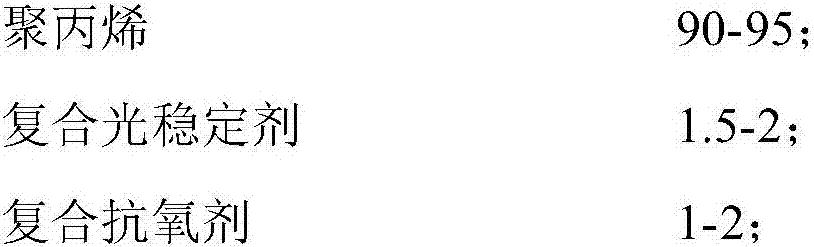

[0042] The preparation method of the polypropylene composition of the foregoing Examples 1-4 includes the following steps:

[0043] Step 1: Weigh each raw material in parts by weight;

[0044] Step 2: Mix polypropylene, composite light stabilizer, composite antioxidant and dispersant in a high-speed mixer for 3 minutes to obtain a mixture;

[0045] Step 3: Stir the ultrafine carbon black and coupling agent mixer for 5 minutes to obtain a mixture;

[0046] Step 4: Extrude the mixture in step 2 and the mixture in step 3 from the main feed port and side feed port of the twin-screw extruder to extrude and granulate, and finally obtain the product; the processing temperature is 200°C, the screw speed It is 500RPM, the screw length to diameter ratio is greater than 40, the temperature control zone of the extruder is greater than zone 8, and the side feed port is located in zone 4 or zone 5.

[0047] Table 2

[0048]

[0049] The experimental method in Table 2 is tested in accordance with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com