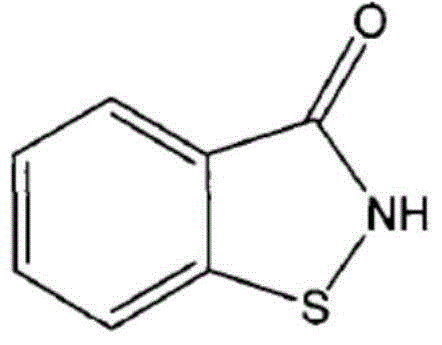

Solid waste reutilization technique in BIT (1,2-benzoisothiazolyl-3-one) production

A process and solid technology, applied in the field of solid waste recycling process in BIT production, can solve the problems of affecting economic effects, backward technical level, high cost, increase economic benefits, solve the problem of three wastes, and realize the effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Mix 150kg of waste with 300kg of solvent chlorobenzene, dissolve completely, add 99kg of solid light at 40°C while keeping warm, there is no obvious heat release, and the gas is continuously released. The reaction is detected by HPLC, and the active ingredient content in the mixture is less than 0.5%. The temperature was raised to 60°C, 64Kg of ammonium chloride was added, and the temperature was raised to reflux. After the reaction is complete, add 10Kg of water, feed chlorine gas, analyze and monitor with HPLC during the process, the raw material disappears, raise the temperature to 80°C, filter the solid, distill the filtrate to recover the solvent, dissolve the solid with liquid alkali, adjust the pH to 12, the solid is completely dissolved, add Stir the activated carbon, filter the activated carbon, add hydrochloric acid to the filtrate to adjust PH=5, precipitate solids, cool to 20°C, filter to obtain 114Kg solids, and the yield reaches 95% (based on the effective...

Embodiment 2

[0029] Mix 150Kg of waste with 450Kg of solvent toluene, dissolve completely, add 125Kg of thionyl chloride at 30°C, no obvious heat release, and continuous release of gas. The reaction is detected by HPLC, and the active ingredient content in the mixture is less than 0.5%. The temperature was raised to 50°C, and 127Kg of 20% ammonia water was added until the pH=9. Introduce chlorine gas, analyze and monitor with HPLC during the process, the raw material disappears, raise the temperature to 70°C, filter the solid, distill the filtrate to recover the solvent, dissolve the solid with liquid caustic soda, adjust the pH to 11-12, and dissolve all the solid, add activated carbon and stir, filter the activated carbon solid , the filtrate was added hydrochloric acid to adjust PH=4, and the solid was precipitated, cooled to 20° C., filtered to obtain 114Kg solid, and the yield reached 95% (based on the effective content in solid waste).

Embodiment 3

[0031] Mix 150Kg of waste with 300Kg of solvent chlorobenzene, dissolve completely, add 125Kg of thionyl chloride at 20°C, no obvious exotherm is seen, and the gas is continuously released. The reaction is detected by HPLC, and the active ingredient content in the mixture is less than 0.5%. The temperature was raised to 80°C, and ammonia gas was introduced until PH=9. Add 40Kg of water, feed chlorine gas, analyze and monitor with HPLC during the process, the raw materials disappear, raise the temperature to 80°C, filter the solid, distill the filtrate to recover the solvent, dissolve the solid with liquid caustic soda, adjust the pH to 10, dissolve all the solid, add activated carbon to stir, filter Activated carbon was solid, and hydrochloric acid was added to the filtrate to adjust PH=3, and the solid was precipitated, cooled to 10° C., filtered to obtain 114Kg solid, and the yield reached 95% (based on the effective content in solid waste).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com