Production technique of mineral/TiO2 composite granular material

A composite particle and production process technology, applied in the field of mineral/TiO2 composite particle material production process, can solve the problems of production process and production cost limitation, inability to carry out large-scale industrial production, etc., and achieves suitable mass production and production cost. Low, dispersion-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention will be defined more clearly.

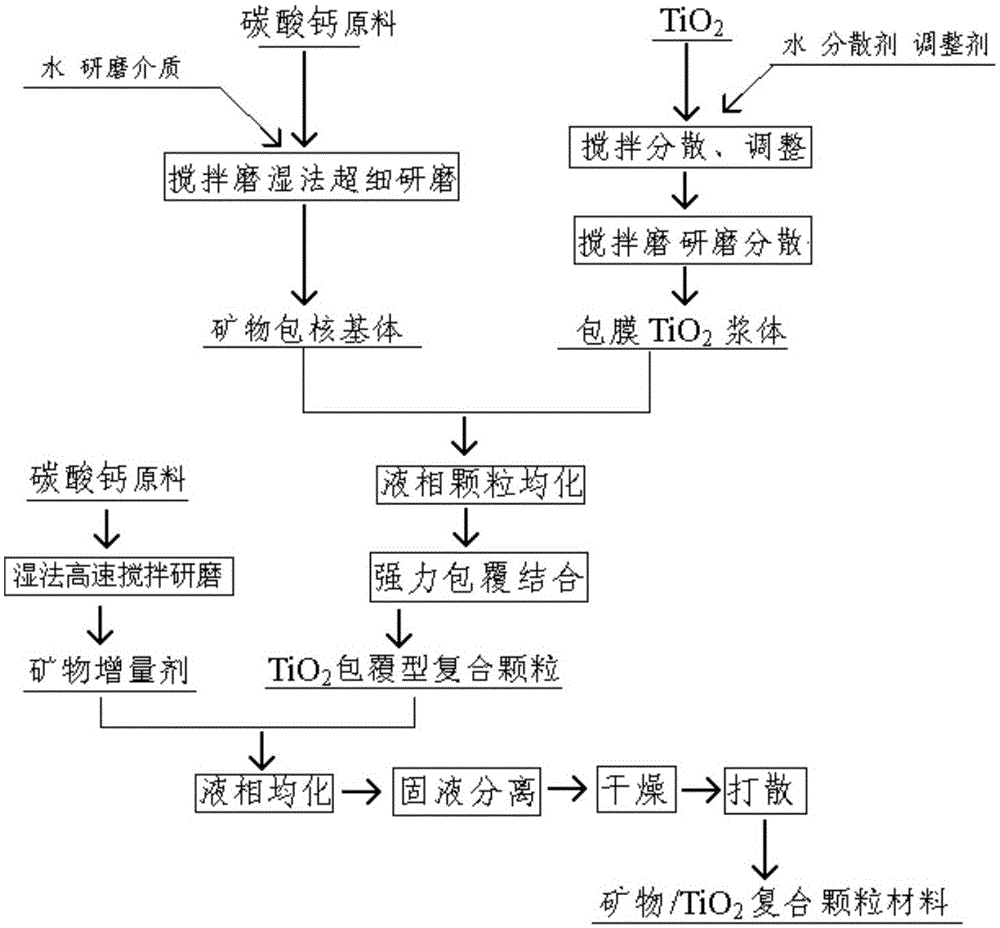

[0035] See figure 1 , A mineral / TiO provided by the present invention 2 The composite particle material production process includes the following steps:

[0036] (1) Preparation of mineral core-coated matrix: add water, dispersant and grinding aid to the calcium carbonate raw materials, and superfinely grind it by the stirring and wet method to make the mineral core-coated matrix;

[0037] (2) Preparation of coated TiO 2 Paste: in TiO 2 Add water, dispersant and regulator to the raw materials, stir and disperse, adjust, grind and disperse, then make coated TiO 2 Slurry

[0038] (3) Preparation of TiO 2 Coated composite particles: the mineral is coate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com