Processing method of capacitor type MEMS sensor and sensor structure

A processing method and sensor technology, applied to piezoelectric devices/electrostrictive devices, microstructure devices composed of deformable elements, microstructure technology, etc., can solve the problems of increasing investment in fixed assets, difficult quality monitoring, thermal expansion coefficient Large gaps and other issues, to avoid investment in fixed assets and ensure consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

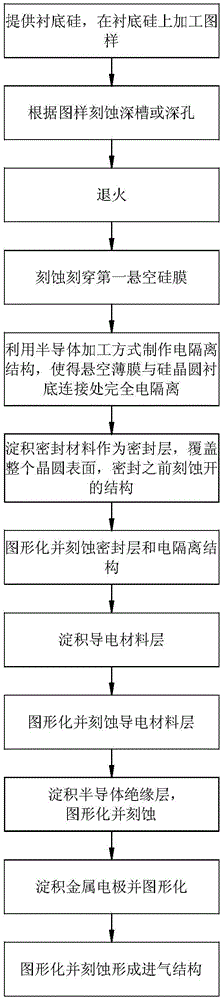

[0052] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0053] Such as Figure 1-14 As shown, in the present embodiment, a processing method of a capacitive MEMS sensor according to the present invention comprises the following steps:

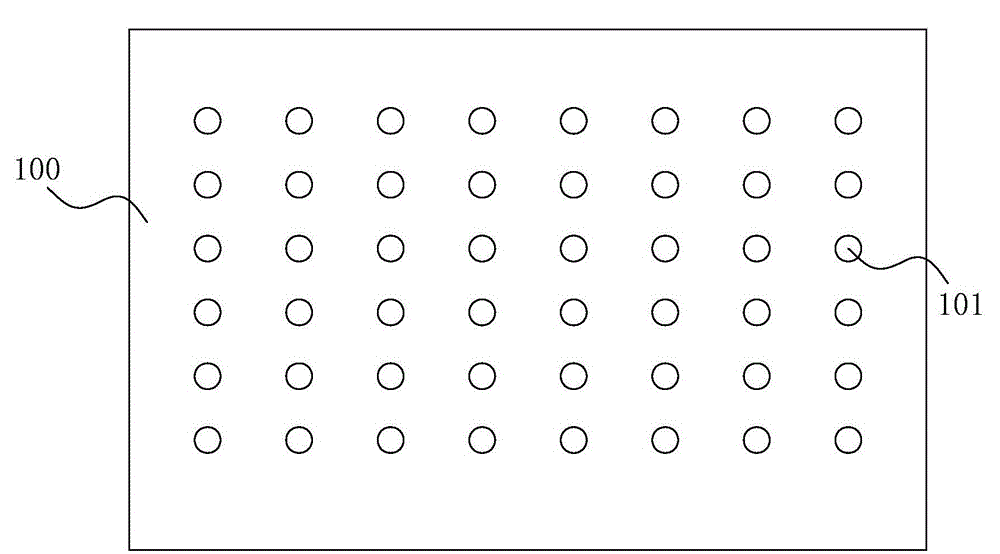

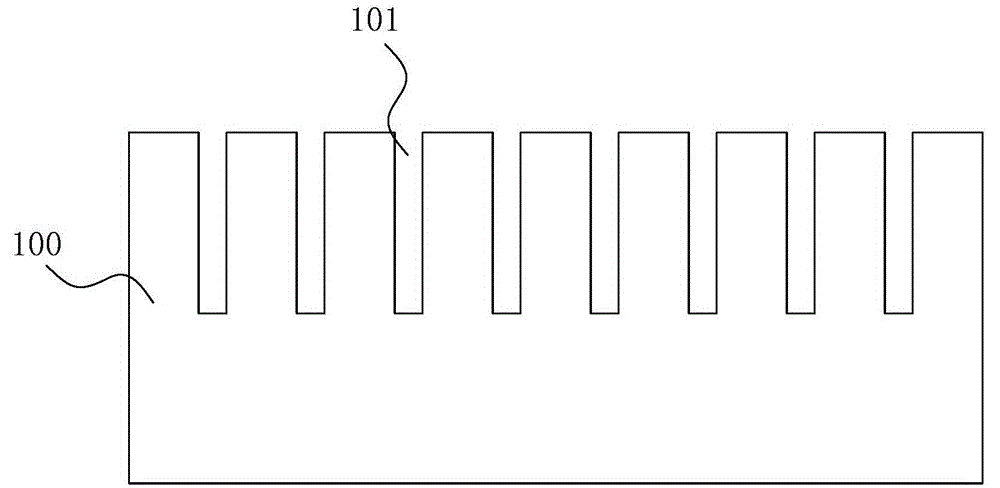

[0054] Step S1, providing a silicon wafer substrate 100, and performing pattern processing on the silicon wafer substrate 100;

[0055] Step S2, etching deep holes 101 on the silicon wafer substrate 100 according to the pattern;

[0056]Step S3, performing annealing treatment on the silicon wafer substrate 100 in a high-temperature oxygen-free environment, so that the silicon atoms on the substrate surface of the silicon wafer 1 are migrated to form a first suspended silicon film 102, a second suspended silicon film 103 and A first cavity 104 located between the first suspended silicon film 102 and the second suspended ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross section width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com