Scraper conveyer detecting device and method

A technology of scraper machine and scraper, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of coal mine production benefit economic loss, failure to protect equipment failure, chain damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The scraper device is installed on the head of the scraper during measurement, so as to prevent the magnetic sensor from being damaged by the objects transported on the scraper during operation.

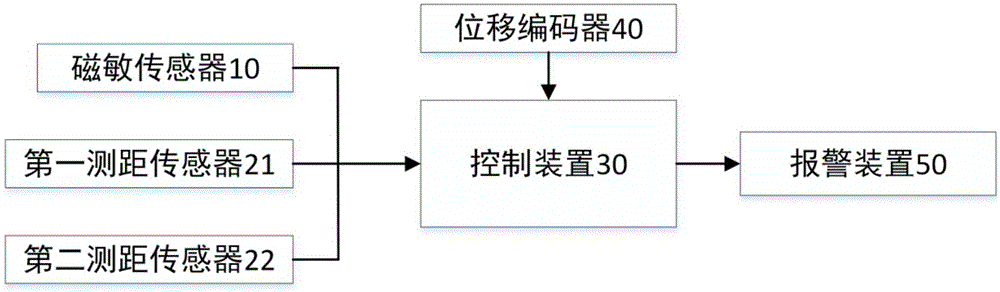

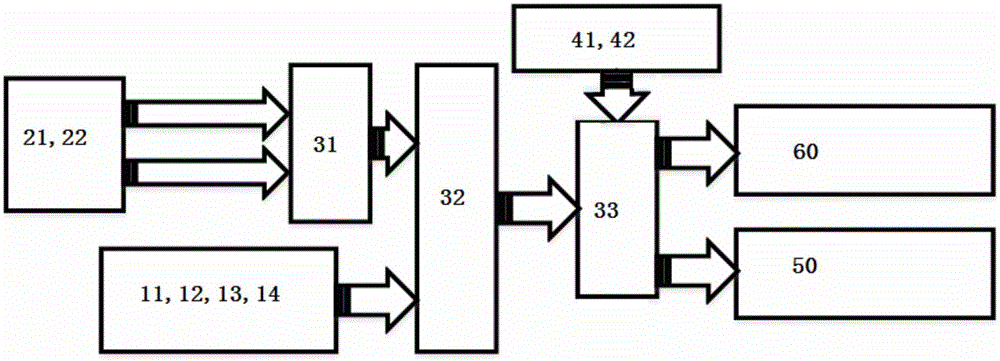

[0036] figure 2 A structural block diagram of a scraper detection device according to another embodiment of the present invention is shown. Such as figure 2 As shown, in this embodiment, the magnetic sensitive sensor 10 may include four magnetic sensitive sensors, which are respectively: a first magnetic sensitive sensor 11, a second magnetic sensitive sensor 12, a third magnetic sensitive sensor 13 and a fourth magnetic sensitive sensor 14. The displacement encoder 40 may include two displacement encoders, namely: a first displacement encoder 41 and a second displacement encoder 42 . The control device 30 may include: a subtractor 31 , a signal processing circuit 32 and an embedded chip 33 . In addition, the scraper detection device may further include a display device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com