Production method and die of prefabricated supporting sleeve used in cooperation with split bolt

A technology for supporting sleeves and pull bolts, which is applied in the direction of manufacturing tools, prefabricated components, ceramic molding machines, etc., can solve the problems of thin sleeve wall thickness, unreasonable force system, and low compressive strength of materials, so as to ensure that the wall body thickness, improved appearance quality, and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

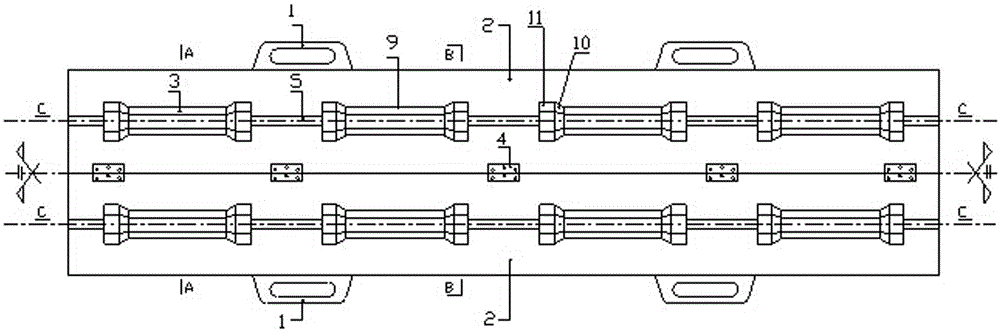

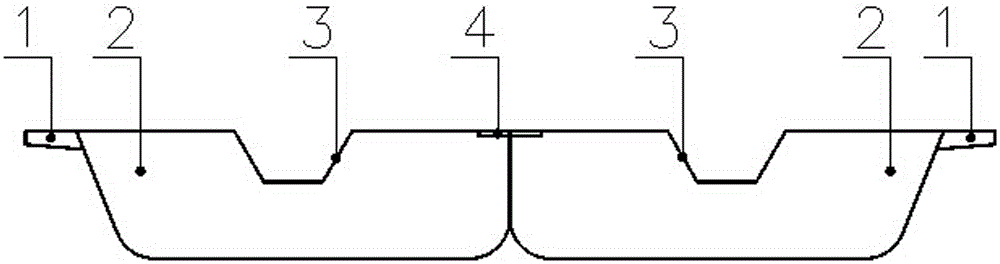

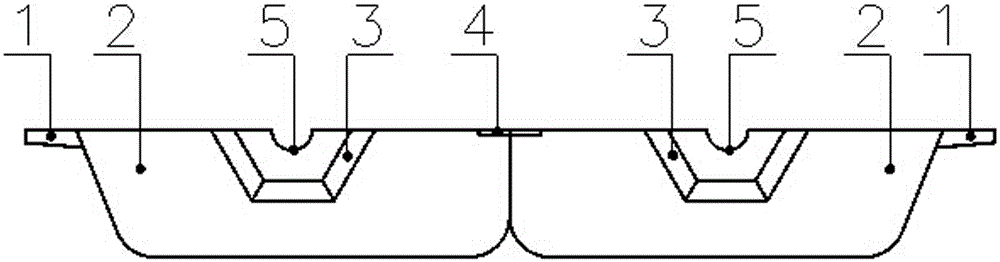

[0024] Such as Figure 1 to Figure 4 As shown, a production mold of a prefabricated support sleeve used in conjunction with pull bolts is provided with two identical sides with split mold handles 1. The mold components are connected side by side through a link hinge 4. The mold includes a mold body 2, located at A number of shaped templates 3 and fixed pipe grooves 5 in the mold body 2, the shaped templates 3 and the fixed pipe grooves 5 are connected, the shaped template 3 is composed of a middle part 9 and two ends, and the ends are frustum-shaped enlargements with the same shape as the middle part Head structure, frustoconical enlargement The head structure is composed of a cone part 10 and an end cylinder part 11 .

[0025] Wherein, the cross-sectional shape of the middle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com