Methanol tower reboiler with fluid uniformly distributing function

A technology of uniform distribution, methanol tower, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of difficult to control pressure loss, unable to meet the uniform distribution of fluid, increase in the number of heating pipes, etc., to achieve the effect of improving the flow state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

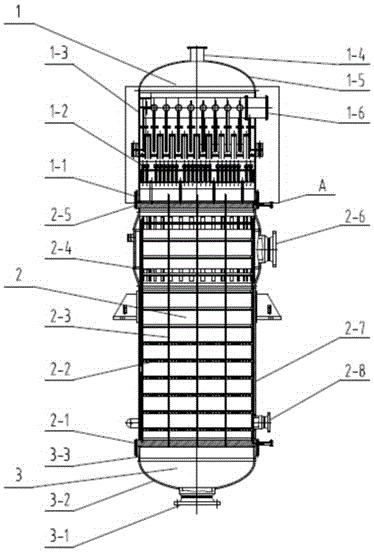

[0066] like figure 1 As shown, the present invention includes an upper tube box 1, a shell-side tube bundle 2 and a lower tube box 3,

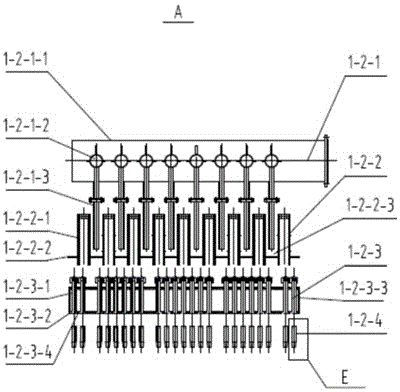

[0067] The upper pipe box 1 includes an upper pipe box equipment flange 1-1, a multi-stage conjoined distributor 1-2, an upper pipe box cylinder 1-3, a gas phase outlet 1-4, an upper head 1-5 and Liquid inlet 1-6, wherein, the upper pipe box cylinder 1-3 is a cylindrical cylinder body, the upper pipe box equipment flange 1-1 is welded on the lower end surface of the upper pipe box cylinder 1-3, and the upper pipe box The upper end surface of the cylinder 1-3 is welded with the upper head 1-5, the gas phase outlet 1-4 is welded on the top of the upper head 1-5, and the liquid inlet 1-6 is welded on the side of the upper pipe box cylinder 1-3, Weld the multi-stage conjoined distributor 1-2 on the inner wall of the cylinder 1-3;

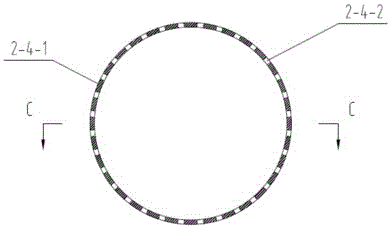

[0068] The shell-side tube bundle 2 includes a lower tube plate 2-1, an ultra-thin baffle grid 2-2, a heating tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com