Energy-saving type garden staff heat pump drying device

A heat pump drying and energy-saving technology, which is applied in heating devices, local agitation dryers, and static material dryers, can solve problems such as unreasonable energy utilization, affecting the drying quality of fruits and vegetables, and difficulty in discharging heat from the drying box. Facilitate water analysis, ensure drying quality, and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the given examples are only used to explain the present invention, and are not intended to limit the scope of the present invention.

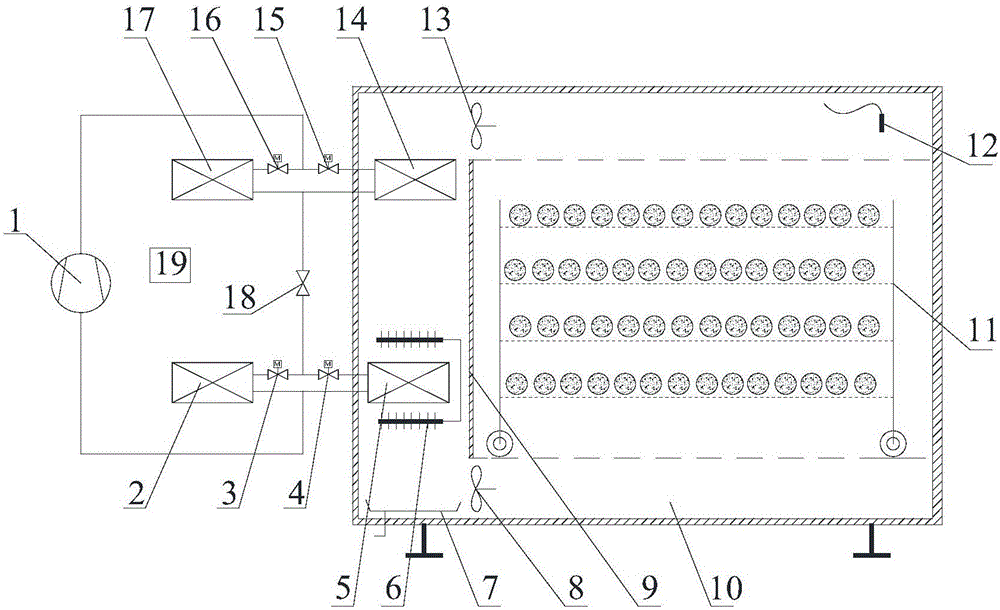

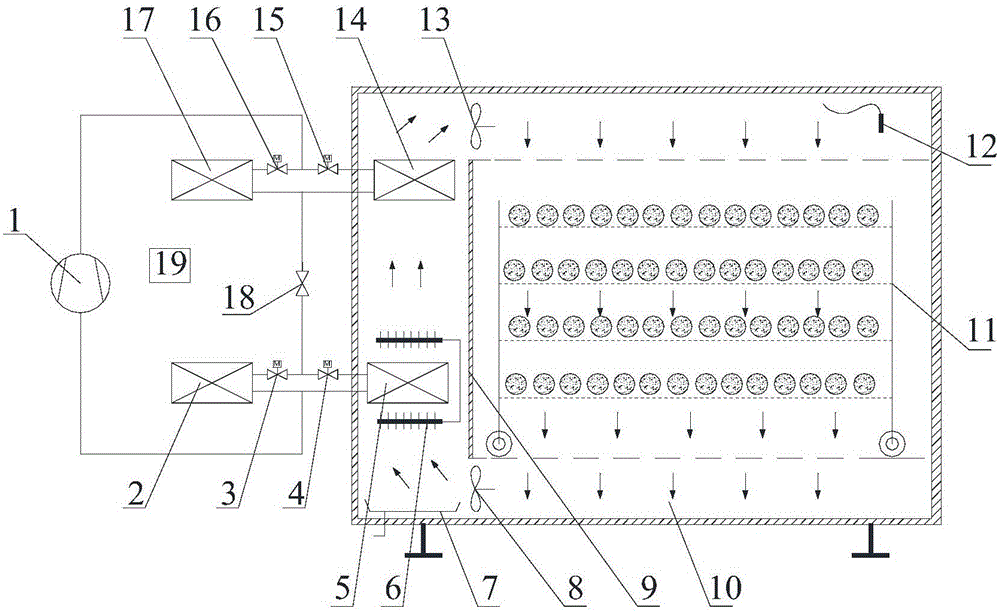

[0022] Such as figure 1 As shown, an energy-saving heat pump drying device for fruits and vegetables consists of a compressor 1, a first evaporator 2, a first electromagnetic shut-off valve 3, a second electromagnetic shut-off valve 4, a second evaporator 5, a heat pipe 6, and a water tray 7 , return fan 8, partition 9, drying box 10, fruit and vegetable rack 11, temperature and humidity sensor 12, air blower 13, second condenser 14, third electromagnetic shut-off valve 15, fourth electromagnetic shut-off valve 16, first condenser 17 , a throttle valve 18, and a controller 19.

[0023] The compressor 1, the fourth electromagnetic shut-off valve 16, the first condenser 17, the throttle valve 18, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com