gas cooler

A gas cooler and cooling chamber technology, which is applied in gaseous chemical plating, chemical instruments and methods, lighting and heating equipment, etc., can solve the problems of increasing driving force, increasing sliding resistance, and increasing the overall size of the device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

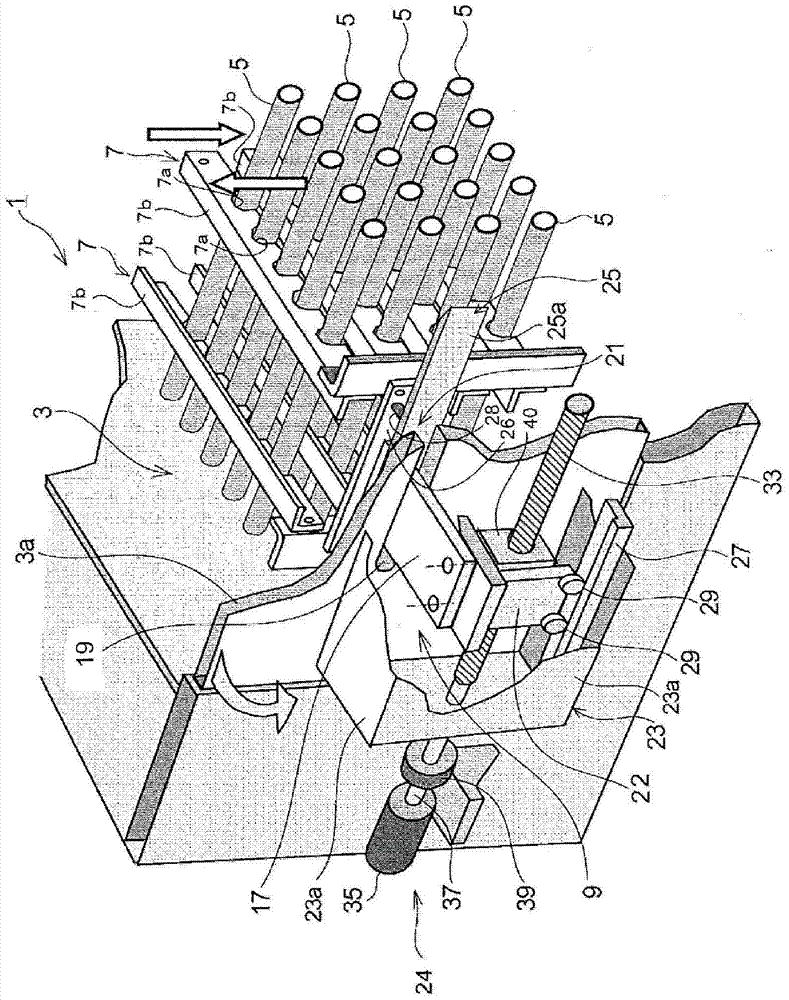

[0030] based on figure 1 The gas cooler 1 according to this embodiment will be described.

[0031] like figure 1 As shown, the gas cooler 1 of this embodiment has: a plurality of cooling pipes 5, which are arranged in parallel in the cooling chamber 3 for gas circulation; and a reciprocating mechanism 9 that reciprocates the dust removal component 7 along the axial direction of the cooling pipe 5 .

[0032] Each configuration will be described in detail below.

[0033]

[0034] Cooling chamber 3 is a chamber for the circulation of exhaust gas, such as figure 1 Flow in the direction perpendicular to the cooling pipe 5 (from bottom to top, or from top to bottom) as shown by the arrow.

[0035] The side wall 3a of the cooling chamber 3 has a door structure and can be opened and closed as shown by the arrow in the figure. By making the side wall 3a openable and closable, maintenance such as replacement of the dust removal member 7 and internal inspection become easy.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com