an hvac system

A system controller and gear technology, applied in the field of HVAC systems, can solve the problems of single function, incompatibility, and inapplicability of ECM motors and motors, and achieve the effect of reducing product models, facilitating management, and reducing R&D costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

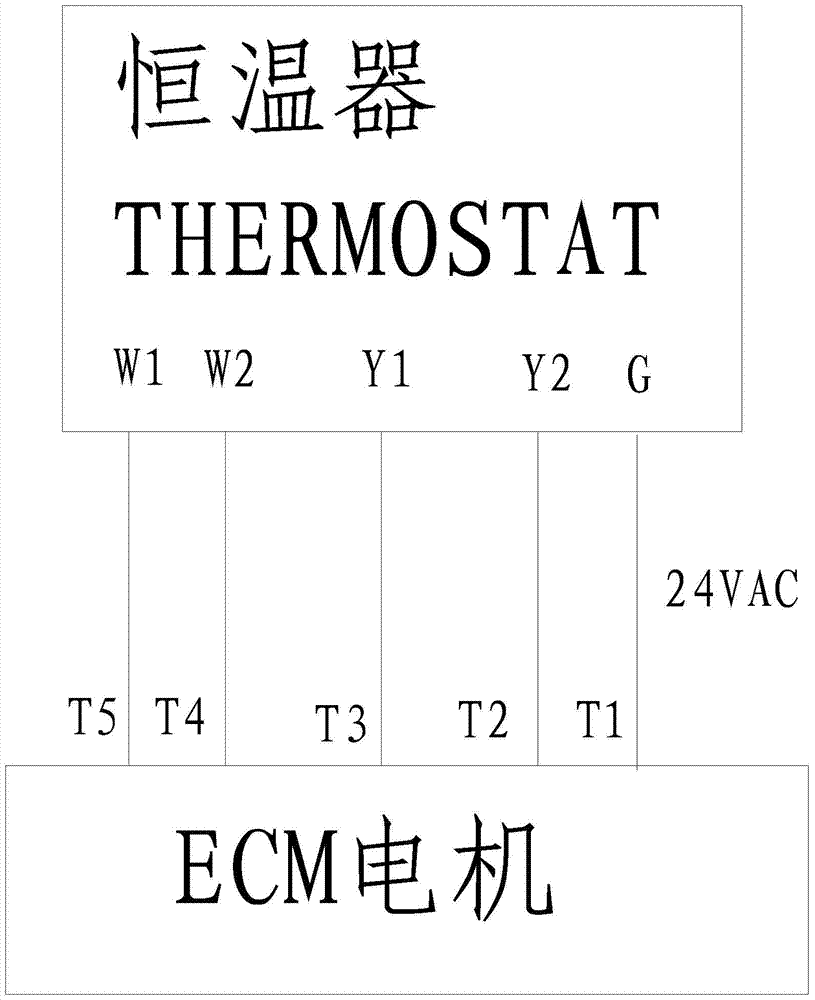

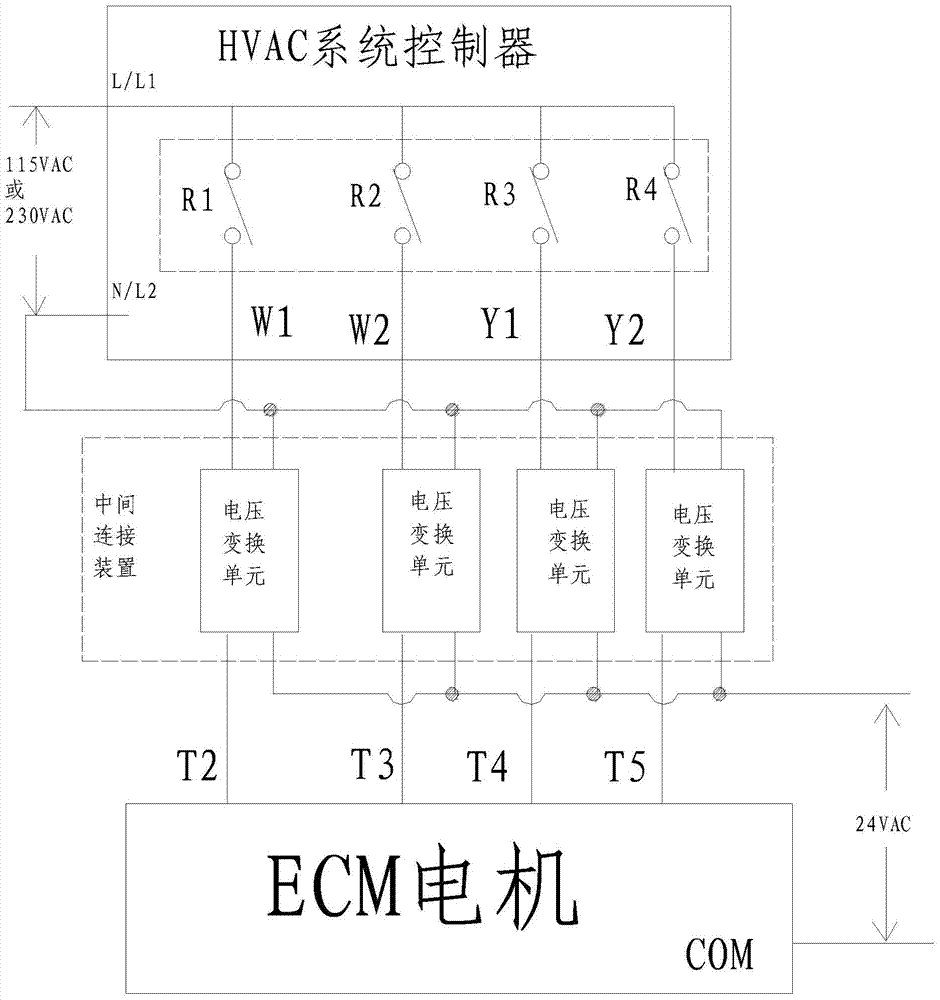

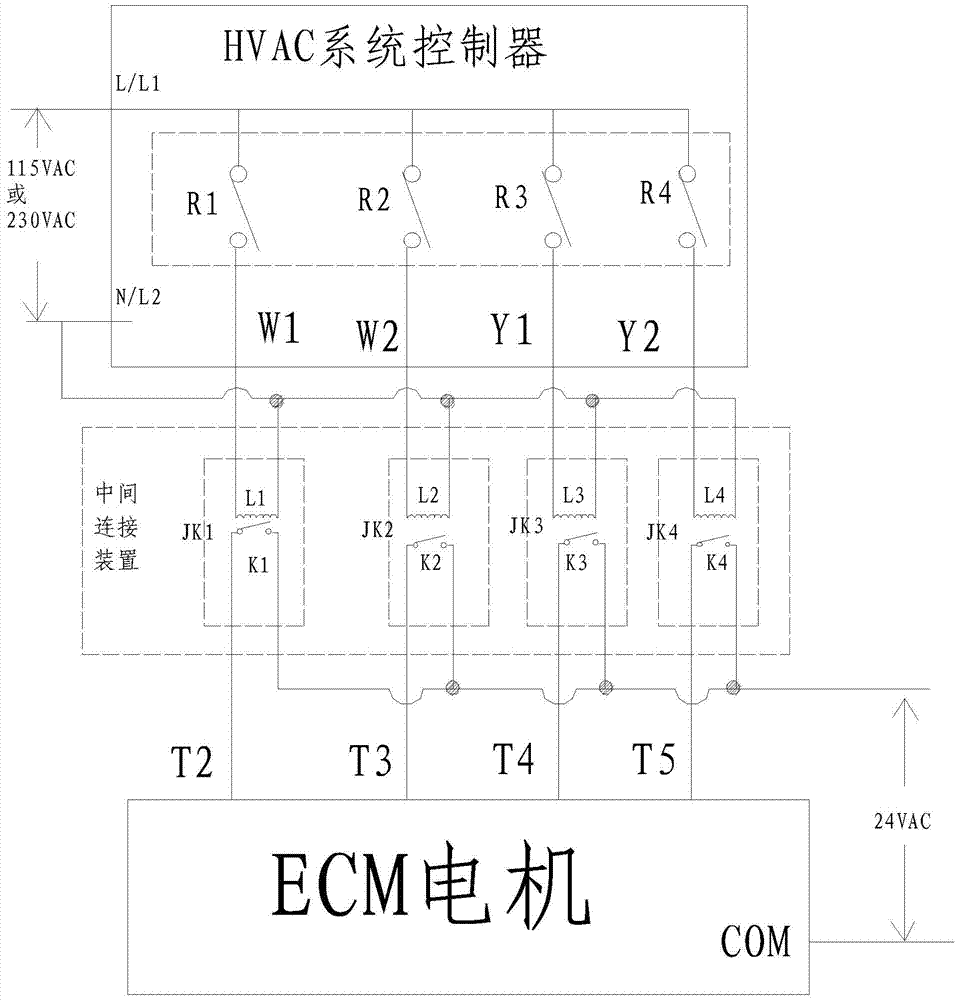

[0043] Such as figure 2 As shown, a kind of HVAC system, described HVAC system originally used PSC fan motor, including HVAC system controller, now replaces PSC fan motor with ECM motor, wherein: HVAC system controller has several output ports connected with the motor W1, W2, Y1, Y2 and two AC input ports L / L1, N\L2, one of the AC input ports L / L1 is respectively connected to the output port W1 through several relays R1, R2, R3, R4 inside the HVAC system , W2, Y1, and Y2 are connected to control a number of relays R1, R2, R3, and R4 so that one of the output ports W1, W2, Y1, and Y2 has an AC signal of 115V or 230V; the ECM motor is set to several There are only one gear input line, only one of the gear input lines is selected to be in the on state, and the rest are selected to be in the off state without power, and the ECM selects the motor according to the gear input line that is selected to be in the on state. operating parameters, and control the motor to run according t...

Embodiment 2

[0049] Such as Figure 9 , Figure 10 As shown, the intermediate connecting device used for HVAC system includes connecting socket 1, connecting lead 2, connecting terminal 3 and several relays 4, wherein connecting lead 2 includes power lead 21L, 21N, first connecting lead 21 of relay, relay second Two connection lead wires 22, 24V AC power lead wire 23 and grounding wire 24, several socket holes 11 are arranged on the connection socket 1, and connection terminals 3 are installed inside the connection socket 11, and some connection terminals 3 are respectively connected with power lead wires 21L, 21N Connection, part of the connection terminal 3 is connected to one end of the first connection lead 21 of the relay 4, the other end of the first connection lead 21 of the relay is connected to one terminal of the switch of the relay 4, and the other terminal of the switch of the relay is connected to the second connection of the relay One end of the lead wire 22 is connected to ...

Embodiment 3

[0052] Such as Figure 11 , Figure 12 As shown, the intermediate connection device used for the HVAC system includes a connection socket 1, a connection lead 2, a connection terminal 3 and a control circuit board 100. The control circuit board 100 is provided with several optocoupler isolation units U1, U2, U3 and U4, wherein The connection leads 2 include power supply leads 21L, 21N, optocoupler first connection leads 210, optocoupler second connection leads 220, 24V AC power supply leads 23 and grounding wires 24. The connection socket 1 is provided with several insertion holes 11. Connecting terminals 2 are installed inside the connecting hole 11, some of the connecting terminals 2 are respectively connected to the power leads 21L and 21N, some of the connecting terminals 2 are connected to one end of the first connecting lead 210 of the optocoupler, and the other end of the first connecting lead 210 of the optocoupler is connected to One output end of the optocoupler iso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com