Solar water heater heat storage unit with safety device and installation method of heat storage unit

A technology for solar water heaters and safety devices, which is applied to solar thermal power generation, heating devices, solar thermal devices, etc., can solve problems such as container damage, equipment heat storage performance decline, safety hazards, etc., and achieves simple structure, easy installation requirements, and easy installation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

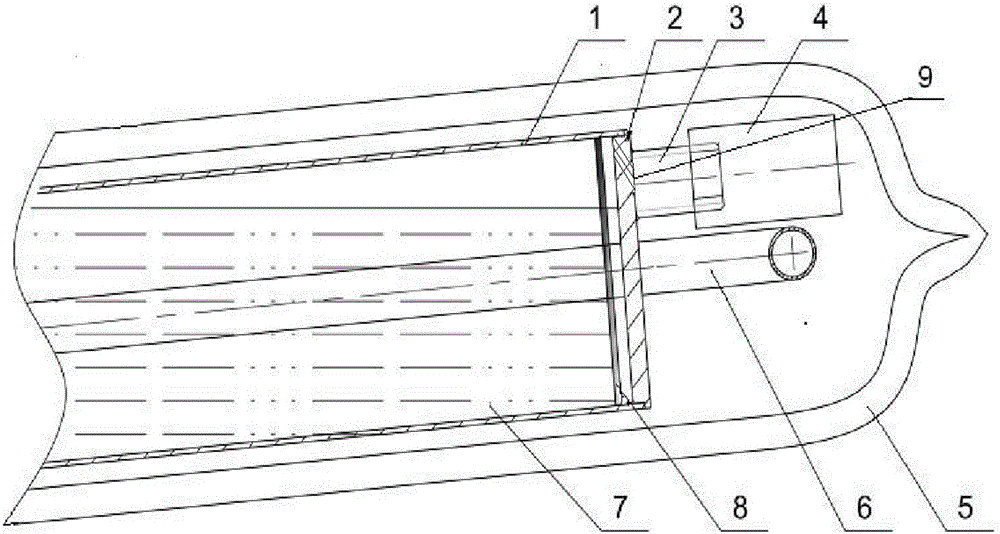

[0027] The heat storage element 1 is a long cylindrical stainless steel container, which contains a certain amount of heat storage material 7 and is provided with U-shaped heat exchange tubes 6 . One end of the cylindrical container is sealed with a flange 2 . The flange 2 is in the shape of an end cap, the maximum outer diameter of which is equal to the outer diameter of the heat storage element, and the smallest outer diameter is slightly smaller than the inner diameter of the heat storage element. There is an inclined pressure relief hole on the outer surface of the flange 2, and the opening of the pressure relief hole inside the flange is located at the top of the smallest outer diameter part. A through-hole stud 3 is welded at the pressure relief hole of the flange, on which a pressure relief valve 4 is installed in a threaded connection. The whole heat storage unit is inserted into the solar vacuum heat collecting tube 5, and the tail of the heat collecting tube is rais...

Embodiment 2

[0029] The heat storage element 1 is a long cylindrical stainless steel container, which contains a certain amount of heat storage material 7 and is provided with U-shaped heat exchange tubes 6 . One end of the cylindrical container is sealed with a flange 2 . The flange 2 is in the shape of an end cap, the maximum outer diameter of which is equal to the outer diameter of the heat storage element, and the smallest outer diameter is slightly smaller than the inner diameter of the heat storage element. An inclined pressure relief hole is formed on the outer surface of the flange, and the opening of the pressure relief hole inside the flange is located at the top of the part with the smallest outer diameter. A metal sheet 8 with a gap is installed near the flange 2. The diameter of the metal sheet 8 is slightly smaller than the inner diameter of the heat storage element, and there is a gap of a certain width with the inner wall of the heat storage element. The gap faces downward ...

Embodiment 3

[0031] The heat storage element 1 is a long cylindrical stainless steel container, which contains a certain amount of heat storage material 7 and is provided with U-shaped heat exchange tubes 6 . One end of the cylindrical container is sealed with a flange 2 . The flange 2 is in the shape of an end cap, the maximum outer diameter of which is equal to the outer diameter of the heat storage element, and the smallest outer diameter is slightly smaller than the inner diameter of the heat storage element. A pressure relief hole perpendicular to the surface is opened on the outer surface of the flange. A U-shaped curved capillary copper tube 8 is welded to the opening of the pressure relief hole inside the flange. The opening of the copper tube 8 is close to the inner wall of the top of the container, and the opening faces and is close to Flange 2 inner surface. A through-hole stud 3 is welded at the pressure relief hole of the flange, on which a pressure relief valve 4 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com