Offshore wind turbine foundation and construction mechanism thereof

A technology for offshore wind turbines and wind turbine foundations, applied in infrastructure engineering, construction, etc., can solve problems that affect the smooth construction of wind turbine foundations, increase construction costs, and affect construction efficiency, and achieve simple structure, improved efficiency and reliability, and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention are described in detail below:

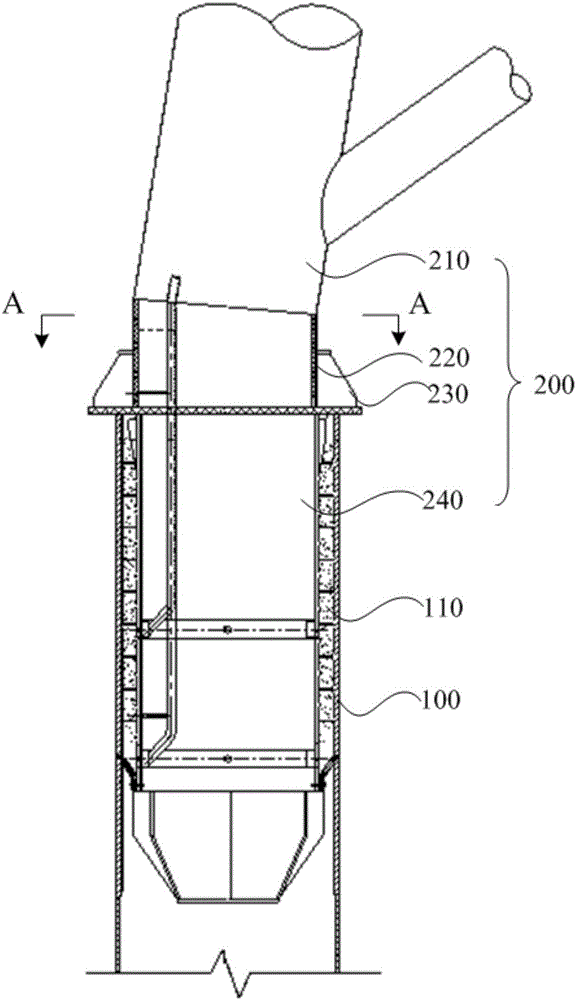

[0040] Such as figure 1 As shown, an offshore wind turbine foundation 200 is fixed in a pipe pile 100 with an opening, and includes a first main body 210, a connecting plate 230 and a second main body 240 arranged in sequence from top to bottom, and the first main body 210 is a supporting structure The main body part, the second main body 240 is a grouting connecting section part, one side of the connecting plate 230 is connected with the first main body 210 , and the other side is connected with the second main body 240 . The pipe pile 100 is fixed on the seabed, and the end of the second body 240 away from the connecting plate 230 extends into the opening of the pipe pile 100 and is fixedly connected with the pipe pile 100 . When the pipe pile 100 deviates from the preset installation position and its deviation exceeds the allowable construction error, it will affect the smooth installation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com