Central air-conditioning air flue with slit valve

A technology for central air conditioning and air ducts, applied in the direction of duct layout, airflow control components, etc., can solve problems such as air duct resistance, energy loss, variable diameter air duct processing or installation difficulties, and achieve the effect of easy layout and flexible layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

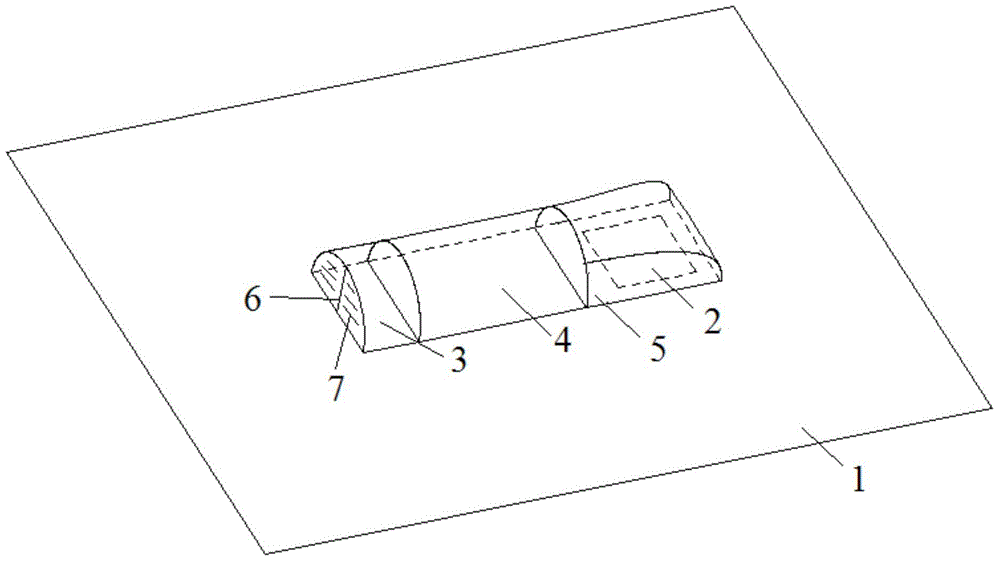

[0007] A central air-conditioning air duct has an air duct body, the width of the air duct body bottom plate 1 is 50cm, and the cross section of the air duct body is a rectangle of 50cm*30cm. It is made of aluminum plate and has a thermal insulation layer on the inner surface of the air duct body.

[0008] The air duct has a total length of 10m from the wind source to the end, and has three air outlets 2. The first air outlet is set 1m away from the wind source. The air outlet is a square with a side length of a=30cm. Between each air outlet The distance is 4m (based on the distance between the center points of the air outlet). The air outlet is opened on the bottom plate 1 of the air duct body. Inside the air outlet, there is an air guide channel installed close to the bottom plate of the air duct body. The structure diagram of the air guide channel is as follows figure 1 shown.

[0009] The air guide flow channel is divided into an air inlet 3, a flow channel body 4 and an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com