Distributed electric control system of heat exchange station

An electronic control system and distributed technology, applied in heating systems, heating methods, household heating, etc., can solve problems such as narrow application range, transformation, and inflexible working methods, and achieve wide application range, standardized maintenance, and reduced The effect of initial installation and maintenance resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

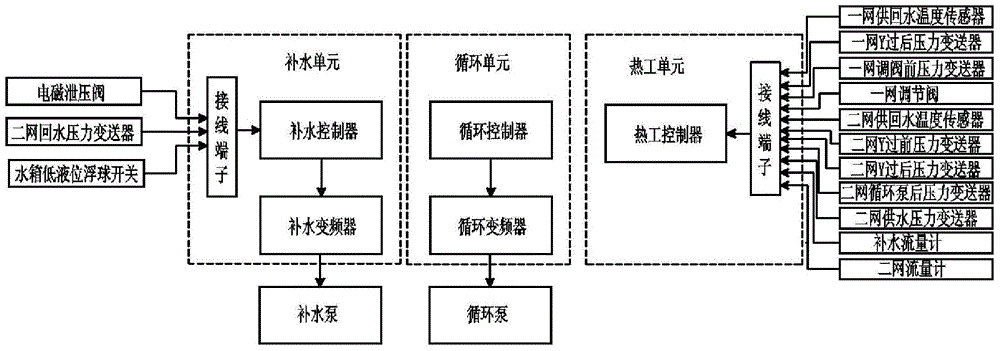

[0033] Embodiment 1: The distributed electric control system of the heat exchange station includes several electric control parts of the units, such as figure 1 As shown, the electric control part of the unit includes a water supply unit and a circulation unit, and the circulation unit and the water supply unit are installed in the electric control cabinet of the electric control part of the unit;

[0034] Such as Figure 6 As shown, the water supply unit includes a water supply unit mounting plate 1-1, a water supply inverter 1-2, a circuit breaker 1-3, an intermediate relay 1-4, a water supply controller 1-5, an AC contactor 1-6, an overheating Relays 1-7, terminal blocks 1-8, and wire slots 1-9, the unit includes an electromagnetic pressure relief valve, a secondary network return water pressure transmitter, a water replenishment pump, a water tank low level float switch, and a water replenishment controller 1-5 is connected to the water supply pump through the water suppl...

Embodiment 2

[0047] Embodiment two: if figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the unit of this embodiment includes a network of supply and return water temperature sensors, a network of pressure transmitters after Y, a network of pre-valve pressure transmitters, and a network of regulators. Valve, secondary network supply and return water temperature sensor, secondary network Y pressure transmitter, secondary network Y pressure transmitter, secondary network circulating pump pressure transmitter, secondary network water supply pressure transmitter, water replenishment flowmeter and the second network flowmeter, the electric control part of the unit includes a thermal unit, and the thermal unit is installed in the electric control cabinet of the electric control part of the unit, such as image 3 As shown, the thermal unit of the unit includes a thermal unit mounting plate 3-1, an AC power supply 3-2, a DC power supply 3-3, a circuit breaker 3-4,...

Embodiment 3

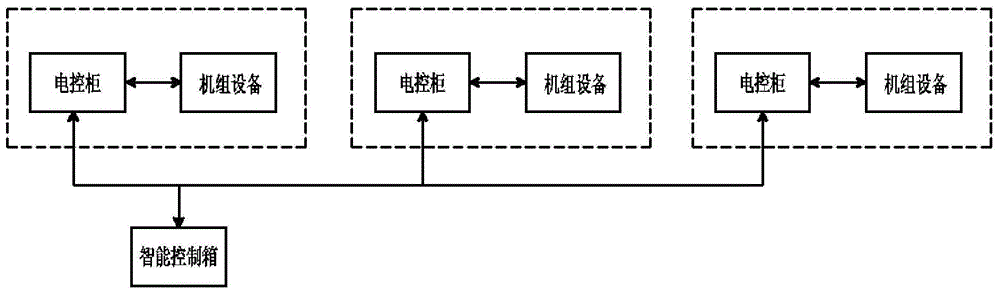

[0055] Embodiment three: as image 3 and Figure 4 As shown, the difference between this embodiment and Embodiment 2 is that the distributed electric control system of the heat exchange station in this embodiment includes an intelligent control unit, and the unit includes an outdoor temperature sensor, a network supervisor supply and return water temperature sensor, and a soft water tank temperature sensor. Sensors, supply and return water pressure transmitters for main network, pressure transmitters for decontamination devices for one network, electric valves for one network, liquid level gauges for soft water tanks and floating and multi-functional electric meters, such as Figure 10 and Figure 11 As shown, the intelligent control unit is installed in the intelligent control box body 4-1, which includes the intelligent control unit mounting plate 4-2, axial flow fan 4-3, DC power supply 4-4, circuit breaker Device 4-5, main controller 4-6, communication module 4-7, termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com