Magnetized fuel economizer for motor vehicle oil pipeline and preparation method of nano catalytic material

A nano-catalytic material and oil pipeline technology, applied in the field of magnetized fuel savers, can solve the problems of rapid movement of unfavorable molecules, affecting fuel saving rate, destroying oil pipelines, etc., to save fuel, prolong service life, and reduce pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

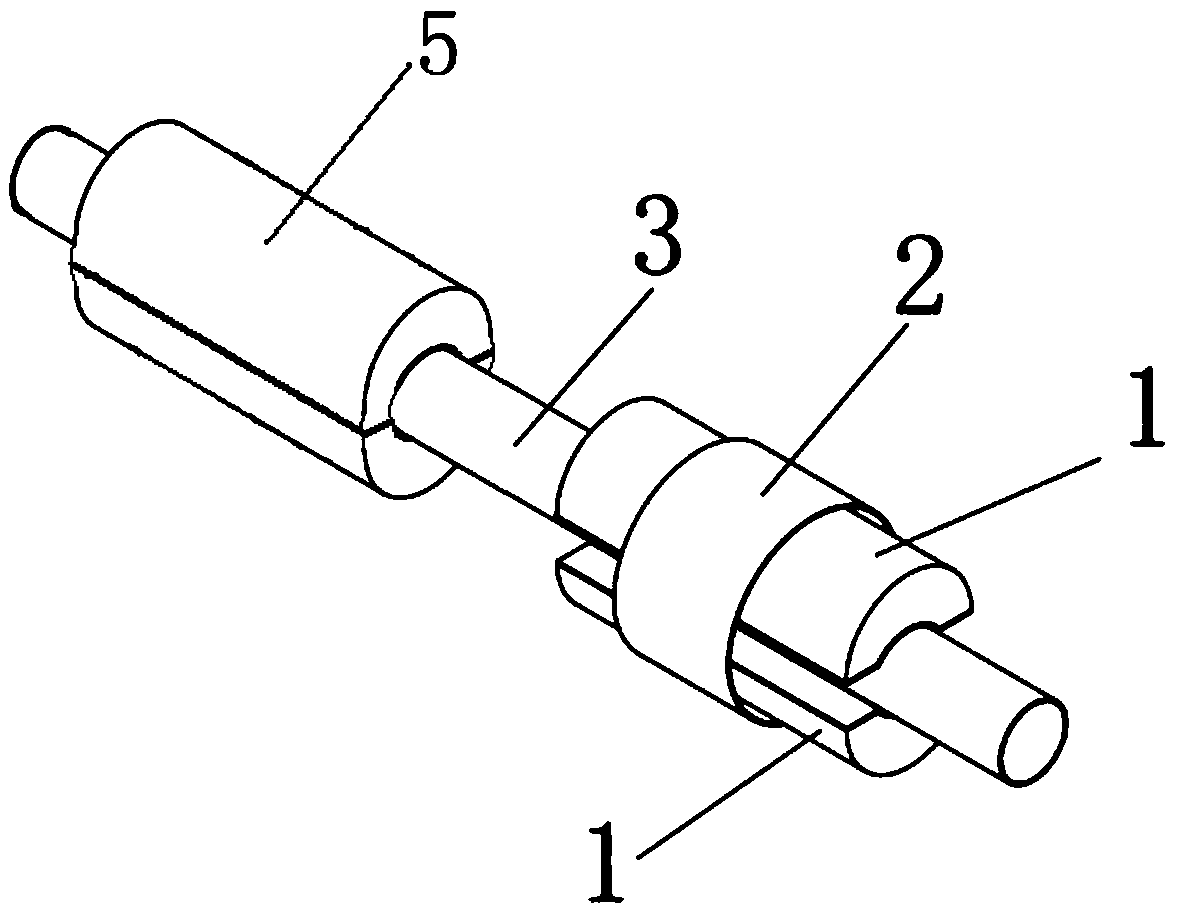

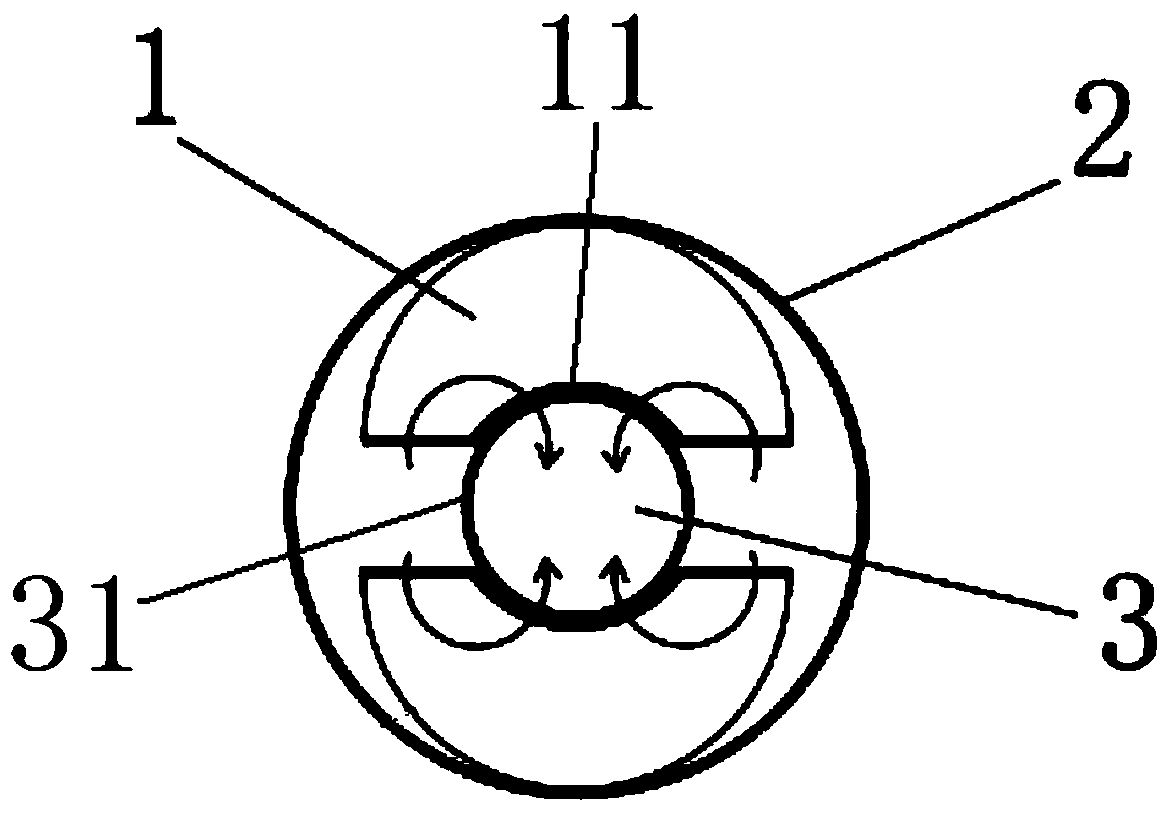

[0028] See attached Figure 1-4 As shown, this embodiment 1 provides a magnetized fuel economizer for motor vehicle oil pipelines, including two fuel-saving units 1 and fastening devices 2 with the same structure, and the two fuel-saving units 1 are fixed on the fuel pipeline 3, and two magnetized units 4, the two magnetized units 4 are also fixed on the fuel delivery pipe 3, and the magnetized unit 4 is fixed at the upper end of the fuel-saving unit 1, specifically, the fuel in the fuel delivery pipe 3 first passes through After the magnetization unit 4, it passes through the fuel-saving unit 1.

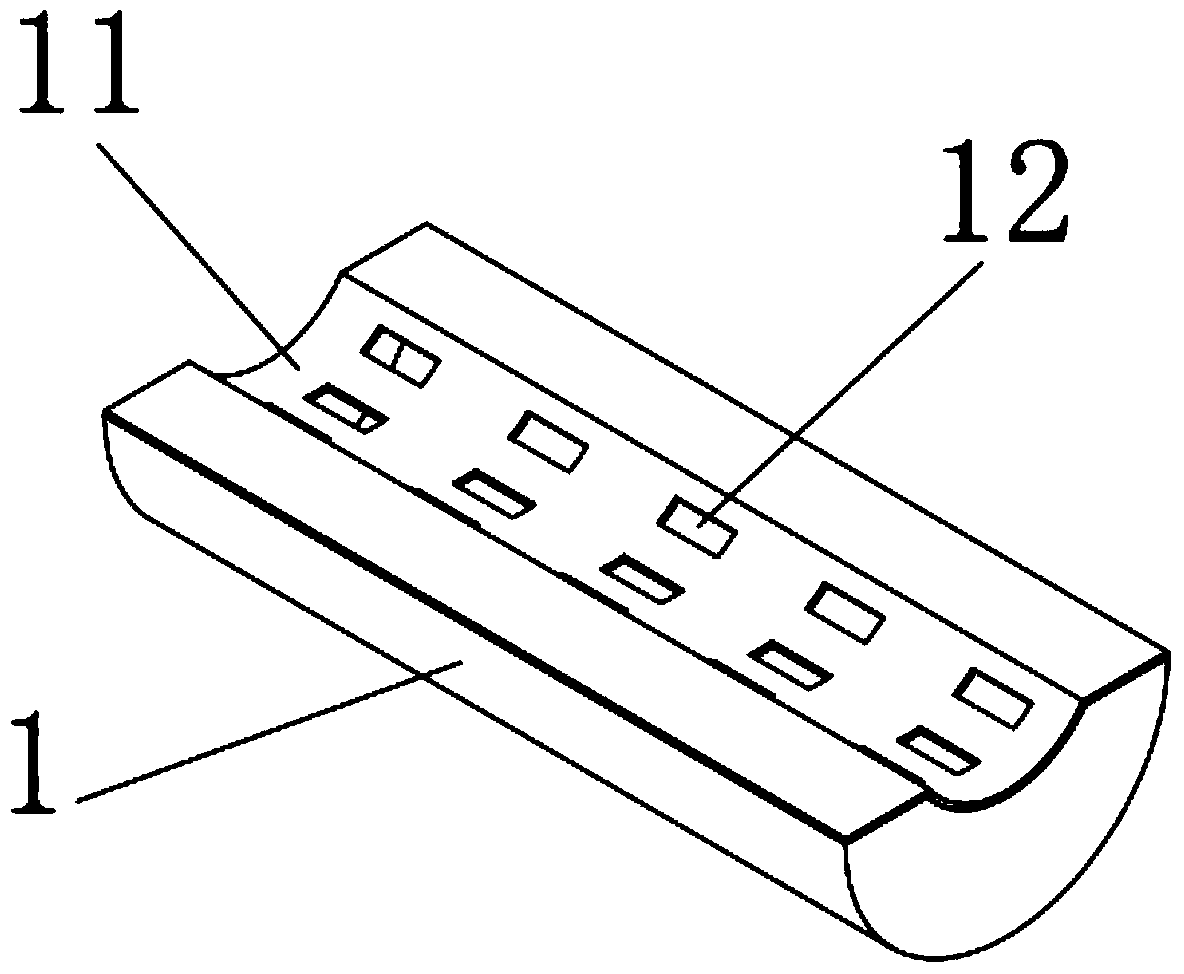

[0029] The two fuel-saving units 1 are arched and hollow inside to form an accommodating cavity 14. The two fuel-saving units 1 with the same structure are arranged correspondingly, but do not touch each other. The arches of the two fuel-saving units 1 form a The catalytic channel, the motor vehicle oil delivery pipe 3 is placed in the catalytic channel. The side of the two fuel-s...

Embodiment 2

[0044] The content of this embodiment 2 is the same as that of the above embodiment, the only difference is that the groove wall 11 on the inner side of the fuel-saving unit 1 of this embodiment is detachable, and the catalytic hole 12 is arranged along the axial direction of the groove. There are 3 rows, each row has 7, and the fastening device 2 is a rope.

Embodiment 3

[0046] The content of this embodiment 3 is the same as that of the above embodiment, except that the catalytic holes 12 of this embodiment are arranged in four rows along the axial direction of the groove wall 11, with five holes in each row. Device 2 is a deck.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com