Pressure Stabilization Technology for Improving the Cementing Quality of High Temperature and High Pressure Wells

A high temperature and high pressure, well cementing technology, applied in wellbore/well components, sealing/isolation, earth-moving drilling, etc. Achieve the effect of reducing the risk of a large amount of fluid intrusion and shortening the waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

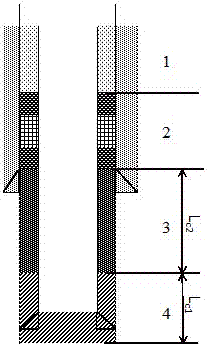

Image

Examples

Embodiment 1

[0013] Embodiment 1 is realized according to the following steps:

[0014] 1. According to the specific gravity of the actual drilling mud and the measured or predicted formation pressure coefficient and formation fracture pressure coefficient, comprehensively consider the weightlessness pressure at the critical point of the cement slurry to ensure that the pressure stability coefficient is not less than 1.0 while not leaking.

[0015] Set formation pressure coefficient as ρ f , the burst pressure coefficient is ρ p , then the formation pressure P f =ρ f gH, Pp=ρ p gH, then, the voltage stability coefficient p is calculated according to the following formula:

[0016]

[0017] Among them, P cmk is the slurry column pressure of the cement slurry in the static glue of 150Pa, MPa; P f is formation pressure, MPa; P cm is the initial annular liquid column pressure, MPa, P cm flw is the weight loss pressure at the critical point of cement slurry, MPa.

[0018] 2. In term...

Embodiment 2

[0020] Example 2 Application of actual drilling operations.

[0021] 1. In a drilling operation, the polymer cement slurry system is used, the predicted formation pressure coefficient is 1.62sg, the formation fracture pressure coefficient is 1.95sg, the cement slurry specific gravity is 2.0sg, the slurry column length is 880m, the annular drilling fluid specific gravity is 1.63sg, and the fluid column The length is 1900m, the specific gravity of the front fluid is 1.0sg, the length of the liquid column is 816m (the flushing fluid is 510m, the spacer fluid is 306m), and the weight loss pressure at the critical point of the cement slurry is 2.95MPa.

[0022] 2. According to the calculation formula of pressure stability coefficient p in embodiment 1:

[0023] , the calculated pressure stability coefficient p=0.92.

[0024] Since the pressure stability coefficient p is less than 1.0, the following measures are used to adjust to ensure that the pressure stability coefficient is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com