A uniform liquid supply system for multi-nozzle high-voltage electrospinning mass production equipment

A high-voltage electrospinning and multi-nozzle technology, which is applied in the direction of feeding solution to the spinneret, textile and papermaking, filament/thread forming, etc., can solve the problem of low production capacity, uneven distribution of spinning solution, and inability to produce nano Fiber membrane and other issues, to achieve the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

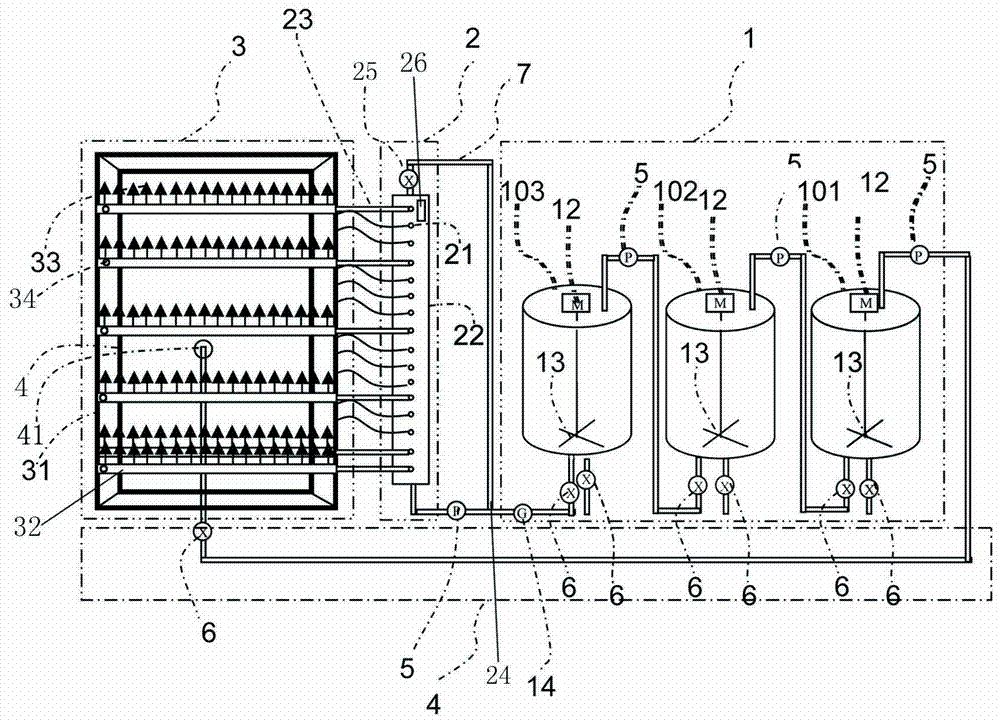

[0026] Such as figure 1 As shown, the present invention provides a uniform liquid supply system for multi-nozzle high-voltage electrospinning mass production equipment, including a spinning solution preparation device 1, a spinning solution distribution device 2, and a spinning unit 3 arranged in sequence along the liquid supply direction And a waste liquid collection tank 4 for collecting waste liquid.

[0027] Wherein, the spinning solution preparation device 1 includes a first stirred tank 101, a second stirred tank 102, and a third stirred tank 103 connected in sequence, and each stirred tank is configured with one or more feed ports, a liquid outlet, and a setting A filter screen at the liquid outlet, a waste liquid port, an electric stirrer, and a water bath heating or water bath cooling device installed on the outer wall of the stirred tank, the water bath heating or water bath cooling device ensures that the temperature in the stirred tank is always maintained at the s...

Embodiment 2

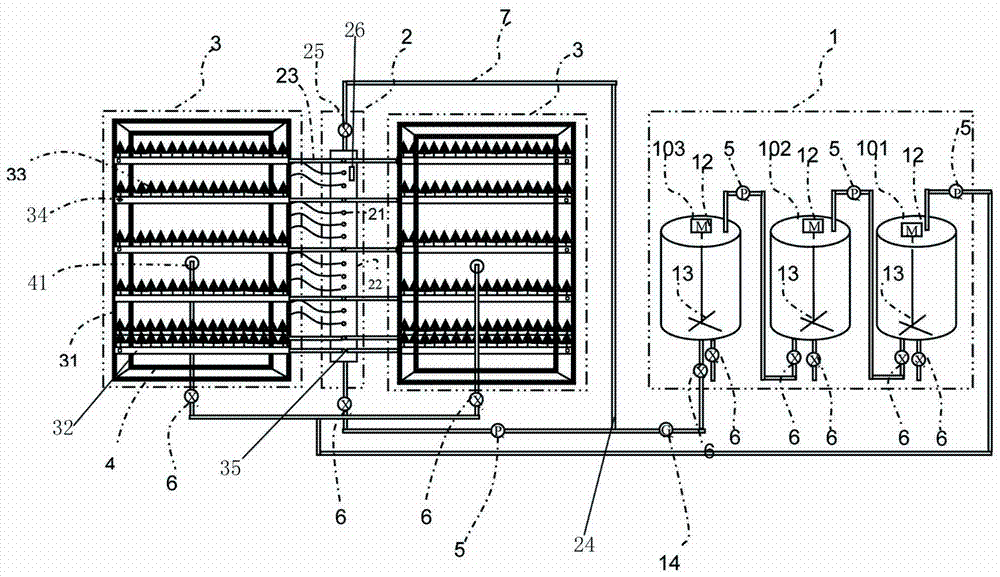

[0033] In order to improve production efficiency and yield, such as figure 2 As shown, the uniform liquid supply system in the second embodiment of the present invention has: a spinning solution preparation device 1 and a spinning solution distribution device 2 arranged in sequence along the liquid supply direction, and symmetrically arranged on both sides of the spinning solution distribution device 2 Two spinning units 3 and a waste liquid collection tank 4 for collecting waste liquid.

[0034] Specifically, the spinning solution preparation device 1 includes a first stirred tank 101, a second stirred tank 102, and a third stirred tank 103 connected in sequence, and each stirred tank is equipped with one or several feed ports, a liquid outlet, A filter screen (not shown) installed at the liquid outlet, a waste liquid outlet, an electric stirrer, and a water bath heating or water bath cooling device installed on the outer wall of the stirred tank, the water bath heating or w...

Embodiment 3

[0041] In order to further improve production efficiency and output, the uniform liquid supply system in the second embodiment of the present invention has: a spinning solution preparation device 1 and a spinning solution distribution device 2 arranged in sequence along the liquid supply direction, symmetrically arranged on the spinning solution An even number of spinning units 3 around the distribution device 2 and a waste liquid collection tank 4 for collecting waste liquid.

[0042] The difference with embodiment one and two only lies in:

[0043] The spinneret units are an even number of symmetrically arranged around the spinning solution distribution device, and the even number of spinneret units have a row of spinneret tubes arranged at equal intervals, and the even number of spinneret tubes are symmetrically arranged on the four sides of the distribution tank. Each spinneret in the row is set at an interval of 2 to 10 cm, and the spinneret is placed horizontally on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com