Titanium alloy target material and method for preparing coating film in rose gold color through titanium alloy target material

A titanium-aluminum alloy, rose gold technology, applied in metal material coating process, sputtering plating, ion implantation plating and other directions, can solve the problem that the ideal effect cannot be achieved, or it needs to be pre-plated for a long time, the color is dull and black, Consumer satisfaction and other issues, to achieve the effect of maintaining color tone, high redness, and rapid color formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A titanium-aluminum alloy target material, the target material includes 82% titanium, 17.9% aluminum, and the balance is trace elements Fe, Zr, Ni, Cu, Si, etc. by weight percentage.

[0031] A coating method for preparing a rose gold color by using the above-mentioned titanium-aluminum alloy target material comprises the following steps:

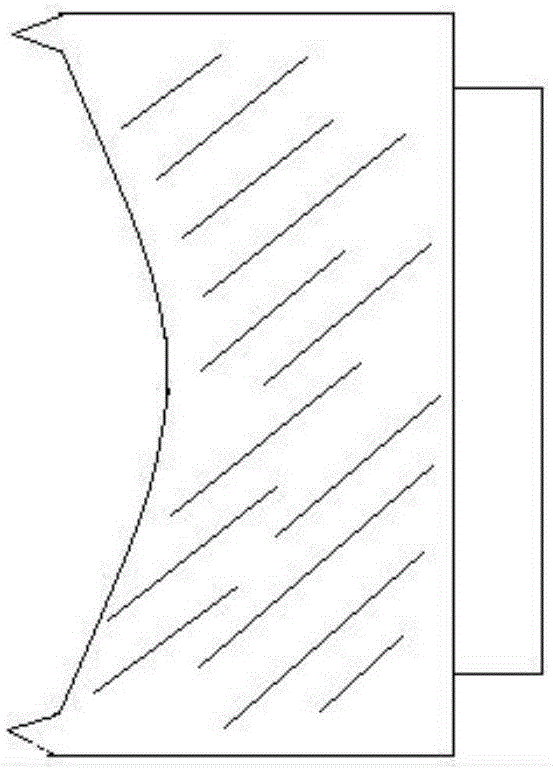

[0032] The smelting and forming process is used to form an ingot, and the target surface of the titanium-aluminum alloy target is machined into a bowl-shaped surface along the direction of the magnetic field. The titanium-aluminum alloy target is arranged in a furnace with 9 targets (9 arc targets are installed in a furnace body), Under the conditions of titanium-aluminum alloy target arc source current 60A, working vacuum 0.8Pa, and bias voltage 60V, firstly use titanium target to prepare titanium nitride for 3 minutes, and then use titanium-aluminum alloy target to fill nitrogen gas to prepare titanium aluminum nitride for 4-7 minut...

Embodiment 2

[0034] A titanium-aluminum alloy target material, the target material includes 84.2% titanium, 15.6% aluminum, and the balance is trace elements Fe, Zr, Ni, Cu, Si, etc. by weight percentage.

[0035] A coating method for preparing a rose gold color by using the above-mentioned titanium-aluminum alloy target material comprises the following steps:

[0036] The smelting and forming process is used to form ingots, and the target surface of the titanium-aluminum alloy target is machined into a conical surface along the direction of the magnetic field. 18 targets of the titanium-aluminum alloy target are arranged in a furnace (18 arc targets are installed in a furnace body), and the Under the conditions of titanium aluminum alloy target arc source current 70A, working vacuum 0.5Pa, and bias voltage 80V, use titanium aluminum alloy target to fill nitrogen to prepare titanium aluminum nitride for 2 to 3 minutes, and then a rose gold coating can be formed on bathroom or stainless stee...

Embodiment 3

[0038] A titanium-aluminum alloy target material, the target material includes 83.3% titanium, 16.4% aluminum, and the balance is trace elements Fe, Zr, Ni, Cu, Si, etc. by weight percentage.

[0039] A coating method for preparing a rose gold color by using the above-mentioned titanium-aluminum alloy target material comprises the following steps:

[0040] Hot isostatic pressing is used to form ingots, and the target surface of the titanium-aluminum alloy target is machined into a saddle-shaped surface along the direction of the magnetic field. 36 targets of the titanium-aluminum alloy target are arranged in one furnace (36 arc targets are installed in one furnace body) ), under the conditions of titanium-aluminum alloy target arc source current 100A, working vacuum 0.5Pa, and bias voltage 100V, use titanium-aluminum alloy target to fill nitrogen to prepare titanium-aluminum nitride for 2 to 3 minutes, and then it can be formed on bathroom or stainless steel products. Rose gol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com