Heat treatment technology for grey cast iron HT250 bearing ring

A technology for bearing rings and gray cast iron, which is applied in the field of heat treatment of gray cast iron HT250 bearing rings, can solve the problems of reduced fatigue strength of rings, affecting the service life of bearings, and large dispersion of hardness values. uncomplicated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

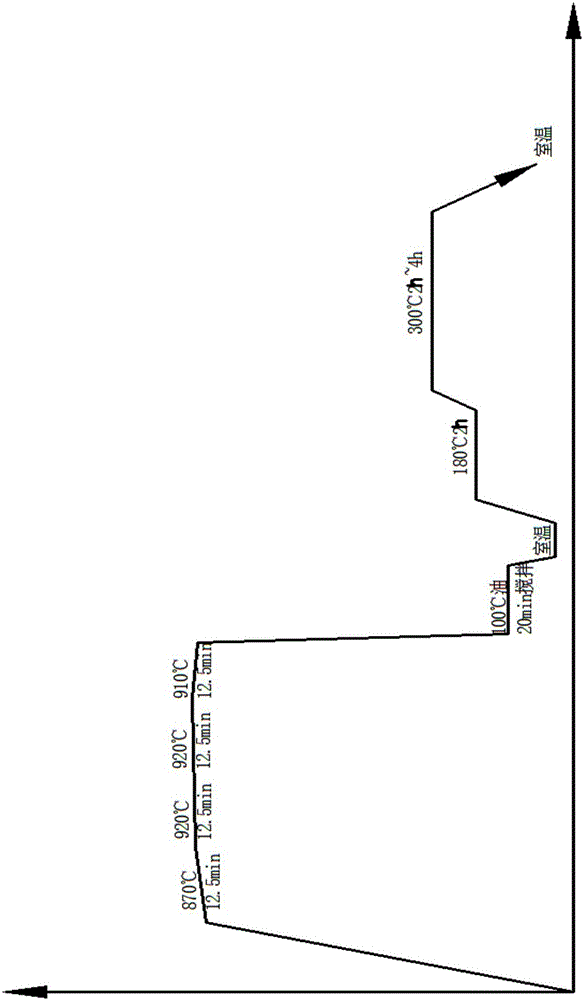

[0021] The heat treatment process includes the following steps:

[0022] (1) Quenching: Adjust the quenching temperature to 890°C and keep it warm for 50 minutes. The holding time is determined according to the wall thickness of the gray cast iron HT250 bearing ring and the amount of furnace for heat treatment, then oil cooling, and the oil temperature is set to 100°C. Then cool to room temperature;

[0023] (2) Step tempering, heat up the gray cast iron HT250 bearing ring to 180°C, keep it warm for 2 hours, then continue to raise the temperature of the gray cast iron HT250 bearing ring to 300°C, keep it warm for 2 hours, and then air cool to room temperature.

[0024] The gray cast iron HT250 bearing ring in this embodiment includes the following components, in mass percentage:

[0025] C 3.0~3.6%; Si 2.0~2.6%; Mn 0.6~1.0%; Cr 0.5~1.0%;

[0026] P below 0.1%; S below 0.1%; the balance is Fe.

Embodiment 2

[0028] The heat treatment process includes the following steps:

[0029] (1) Quenching: Adjust the quenching temperature to 920°C and keep it warm for 60 minutes. The holding time is determined according to the wall thickness of the gray cast iron HT250 bearing ring and the amount of heat treatment furnace, then oil cooling, the oil temperature is set to 110°C, and then Cool to room temperature;

[0030] (2) Step tempering, heat up the gray cast iron HT250 bearing ring to 190°C, keep it warm for 4 hours, then continue to heat up the gray cast iron HT250 bearing ring to 310°C, keep it warm for 4 hours, and then air cool to room temperature.

[0031] The gray cast iron HT250 bearing ring in this embodiment includes the following components, in mass percentage:

[0032] C 3.0~3.6%; Si 2.0~2.6%; Mn 0.6~1.0%; Cr 0.5~1.0%;

[0033] P below 0.1%; S below 0.1%; the balance is Fe.

Embodiment 3

[0035] The heat treatment process includes the following steps:

[0036] (1) Quenching: Adjust the quenching temperature to 900°C and keep it warm for 55 minutes. The holding time is determined according to the wall thickness of the gray cast iron HT250 bearing ring and the amount of furnace for heat treatment, then oil cooling, the oil temperature is set to 105°C, and then Cool to room temperature;

[0037] (2) Step tempering, heat up the gray cast iron HT250 bearing ring to 185°C, keep it warm for 3 hours, then continue to raise the temperature of the gray cast iron HT250 bearing ring to 305°C, keep it warm for 3 hours, and then air cool to room temperature.

[0038] The gray cast iron HT250 bearing ring in this embodiment includes the following components, in mass percentage:

[0039] C 3.0~3.6%; Si 2.0~2.6%; Mn 0.6~1.0%; Cr 0.5~1.0%;

[0040] P below 0.1%; S below 0.1%; the balance is Fe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com