Genetically engineered bacterium producing tetrahydropyrimidine and structuring method and application thereof

A technology of genetically engineered bacteria and tetrahydropyrimidine, which is applied in the field of genetically engineered bacteria producing tetrahydropyrimidine and its construction, can solve problems such as being unsuitable for large-scale industrial production, corrosion of fermentation equipment, long fermentation period, etc., and achieve production efficiency High, low equipment loss, short fermentation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

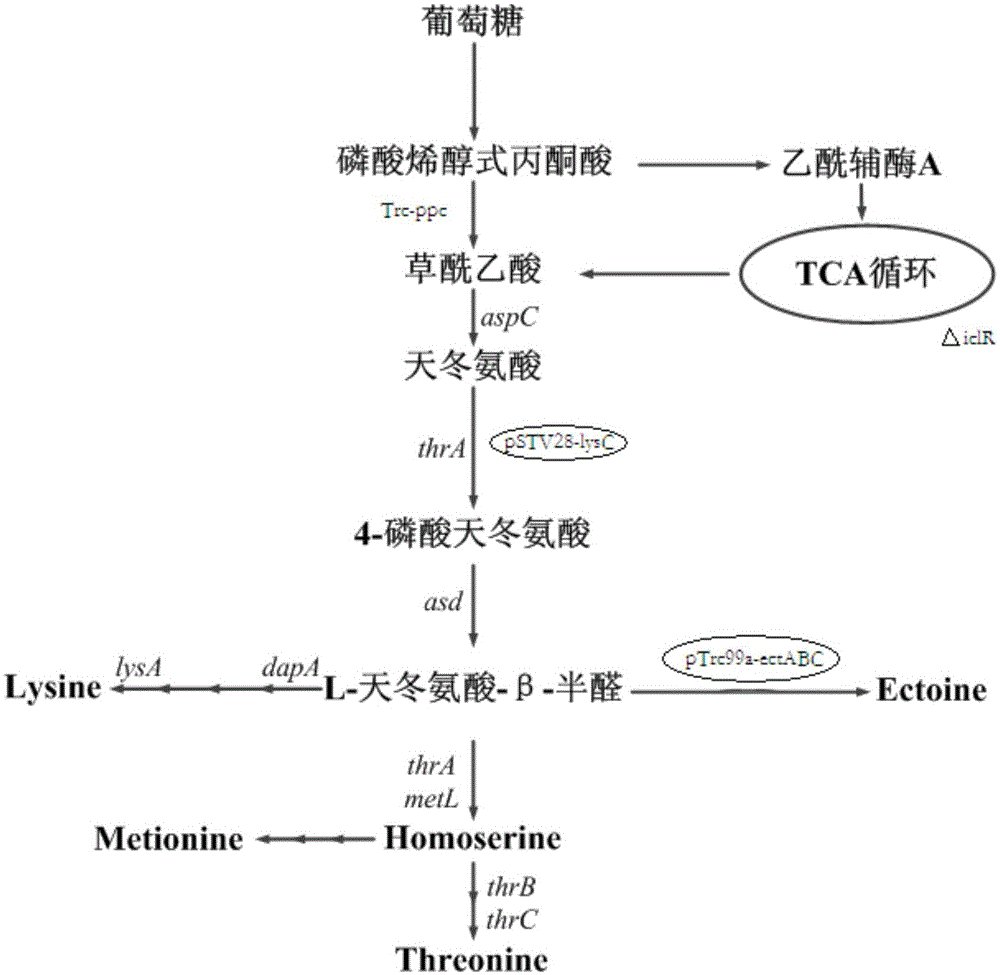

[0054] Construction of Genetically Engineered Bacteria E.coli ECT06 Producing ectoine

[0055] (1) Construction of the metabolic pathway from L-aspartic acid-β-semialdehyde to ectoine.

[0056] ①A pair of primers were designed according to the ectABC gene sequence by using the genome of Halomonas elongatus (CGMCC 1.6329) as a template by PCR technology, and the ectABC fragment was amplified. The pair of primers respectively comprise enzyme cutting sites EcoR I and BamH I.

[0057] ②Use Takara restriction endonucleases EcoR I and BamH I to double digest step ① to obtain the target fragment and pTrc99a vector plasmid, and obtain ectABC and pTrc99a linear fragments with the same cohesive ends.

[0058] ③ Use Takara T4 DNA ligase to connect the two target fragments obtained in step ② to obtain the target vector pTrc99a-ectABC.

[0059] ④ Transform the vector obtained in step ③ into E.coli W3110 (ATCC 27325) to obtain E.coliECT01

[0060] (2) Knockout of thrA gene

[0061] ① Th...

Embodiment 2

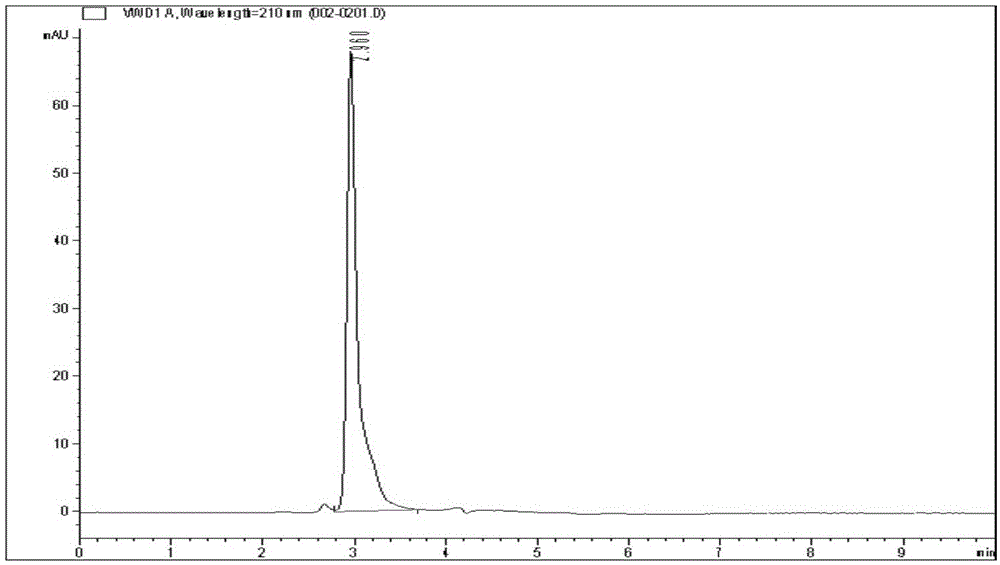

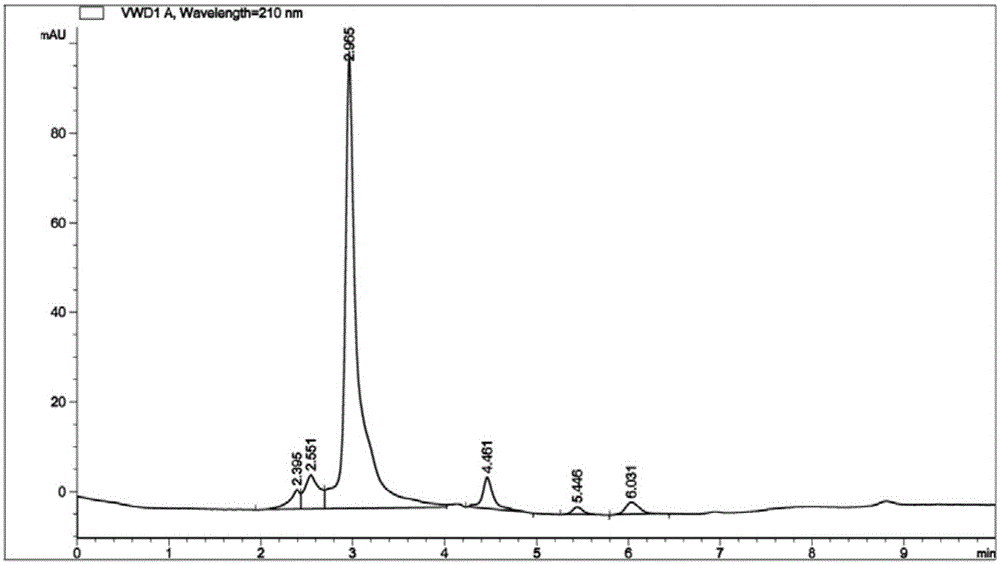

[0088] The specific steps for the fermentation, cultivation and detection of the genetically engineered bacterium E.coliECT06 producing ectoine are as follows:

[0089] (1) Activate the genetically engineered bacterium (E.coli ECT06 engineered bacterium) producing ectoine by using the complete bacterial medium, and culture at a constant temperature of 37°C for 12 hours;

[0090] (2) Transfer the above-mentioned activated slant to the second-generation activated slant, and incubate at a constant temperature of 37° C. for 10 h;

[0091] (3) Use an inoculation loop to scrape a ring of strains into a 500mL round-bottomed conical flask with a liquid volume of 30mL, and incubate at 37°C and 200rpm for 7h;

[0092](4) Use a pipette to inoculate the fermentation shaker flask according to 10% inoculum amount. The fermentation bottle is a 500mL baffled Erlenmeyer flask with a liquid volume of 30mL, cultivated at 37°C and 200rpm for 28h; Add ammonia water to maintain the pH at 7.2, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com