Polytetrafluoroethylene synthesis material

A technology of polytetrafluoroethylene and synthetic materials, which is applied in the field of composite materials, can solve problems such as uneven texture and inconsistent wall thickness uniformity, and achieve the effects of improving product quality and stability, reducing tolerance range, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the examples.

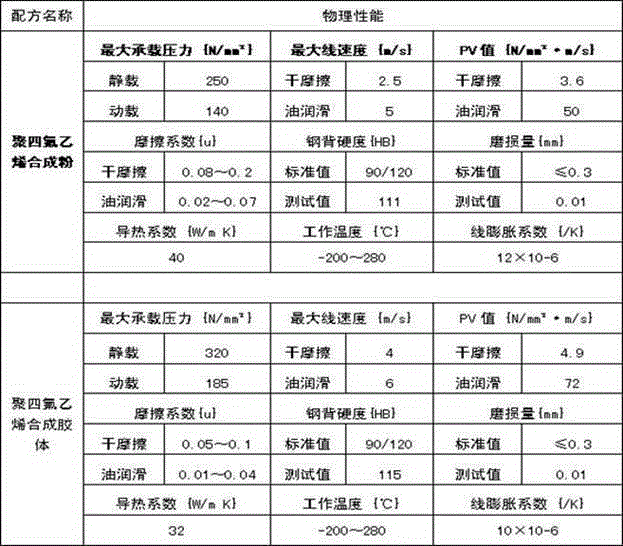

[0009] A polytetrafluoroethylene synthetic material, which contains polytetrafluoroethylene powder, crystal glass fiber, lead powder, polytetrafluoroethylene synthetic emulsion, and liquid wear-resistant material, with a weight ratio of 2.7:1.5:2:1.25:4.5 .

[0010] PTFE synthetic emulsion is made by mixing 70% PTFE emulsion and 30% graphite powder. Take out the polytetrafluoroethylene emulsion and graphite powder in a ratio of 7:3, and mix them at a temperature below 14°C for 10 minutes, and then cool them at a temperature below 5°C for more than 12 hours. Higher viscosity.

[0011] The liquid wear-resistant material contains 0.5%~1% ammonia by weight, 3.5%~4.5% molybdenum disulfide, 2%~3% nodular ink molecules, 1%~1.5% nickel, and the rest is copper, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com