Hot press molding mechanism for electrode lugs of lithium-ion power batteries

A power battery, hot-press forming technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of glass strength not meeting the specification requirements, difficult to find and remove defective products, low production efficiency, etc., and achieve product quality. Stable and reliable, the effect of heating technology is stable, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention provides a hot press forming mechanism for tabs of lithium-ion power batteries. In order to make the object, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail with reference to the accompanying drawings and examples. It should be understood that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

[0016] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

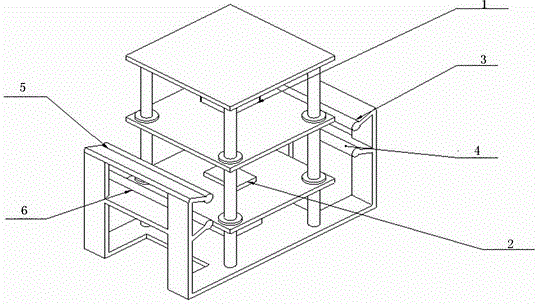

[0017] The heat press forming mechanism of the tab of the lithium-ion power battery includes an intermediate heat press mechanism and a metal conductor heating mechanism for hot pressing the tab glue and the metal conductor together. The hot-pressing heads 1 and 2 driven by the cylinder are equipped with two sets of left and right metal belt heating mechanisms on both sides of the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com