Hydraulic gear shifting device used for numerically-controlled machine tool

A technology of CNC machine tools and shifting devices, which is applied in the direction of driving devices, metal processing machinery parts, metal processing equipment, etc., can solve problems such as gear noise, and achieve the effects of low noise, stable equipment operation, and compact and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

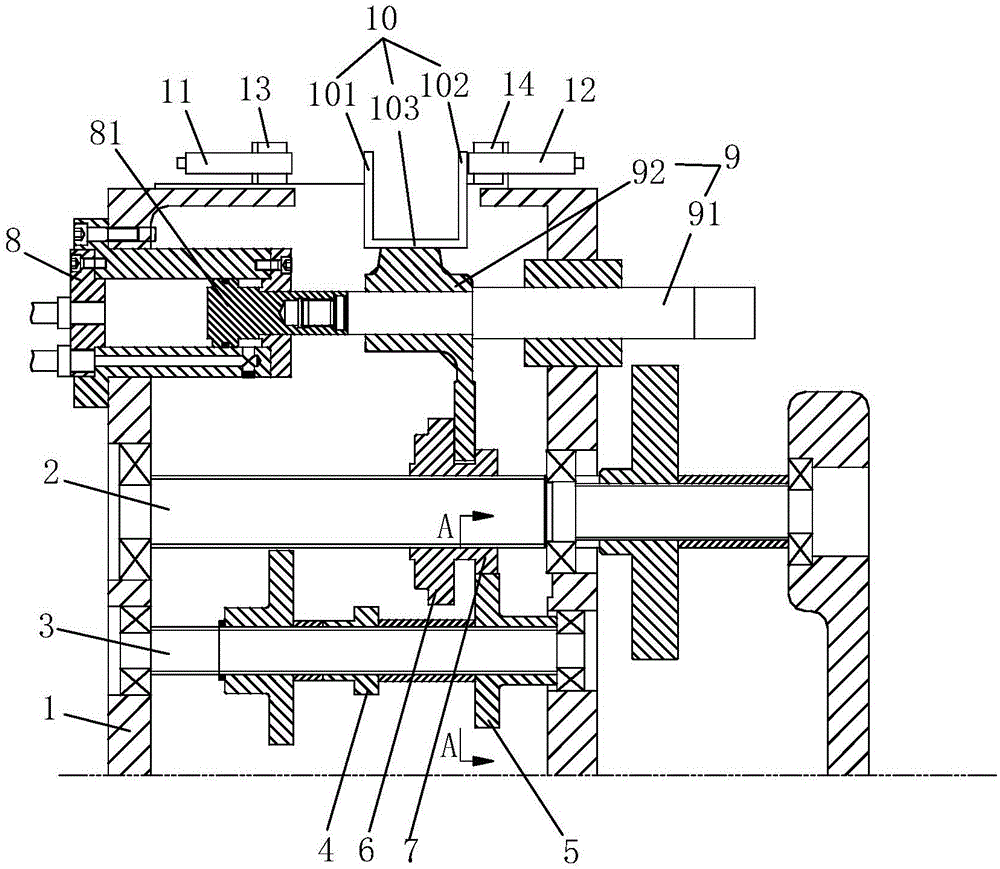

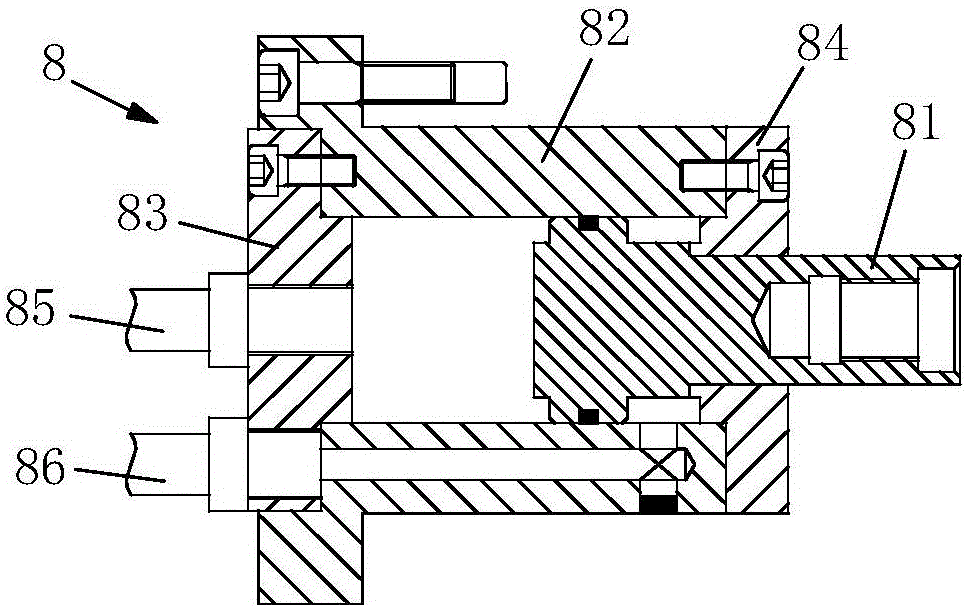

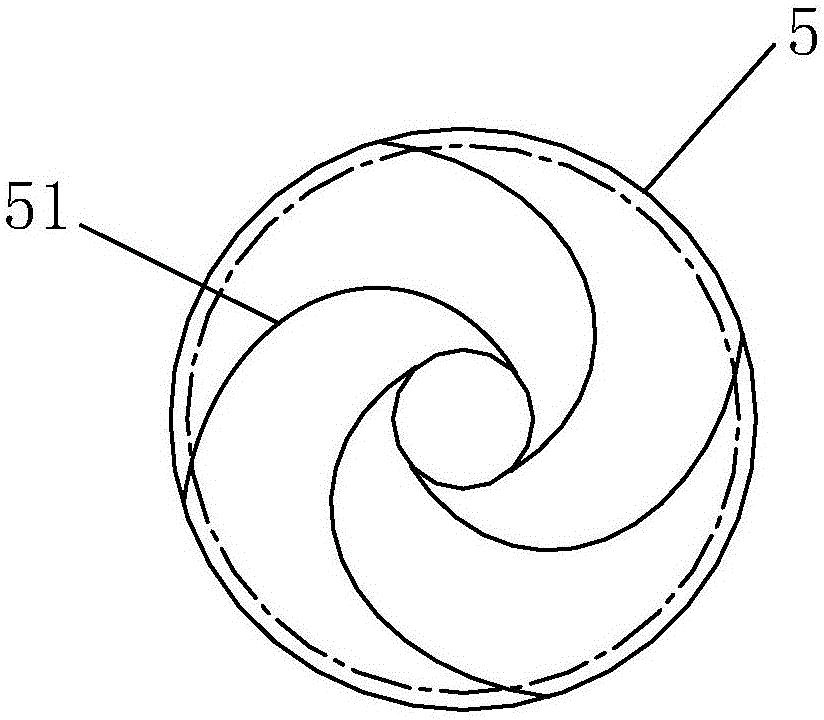

[0016] Such as figure 1 As shown, a hydraulic shifting device for a numerically controlled machine tool includes a gear box 1, and lubricating oil is arranged in the box 1. The improvement lies in: the first gear shaft 2 and the second gear shaft 3 arranged in parallel in the upper and lower directions are arranged in the gear box body 1; The three gears 4 and the fourth gear 5, the double sliding gears include the first gear 6 meshing with the third gear 4 and the second gear 7 meshing with the fourth gear 5, and the hydraulic pressure is also integrated in the gear box 1. The oil cylinder 8, the piston 81 of the hydraulic oil cylinder 8 drives the double sliding gear to slide axially along the first gear shaft 2 through the connecting piece 9, so as to realize the meshing between the first gear 6 and the third gear 4 or the second gear 7 and the first gear Two states of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com