Automatic tin soldering device

An automatic welding and soldering technology, which is applied in the directions of tin feeding devices, welding positions, welding equipment, etc., can solve the problems of pipe blockage, deviation feeding, and low tin feeding position accuracy, and achieves good processing accuracy, simple appearance, and easy replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

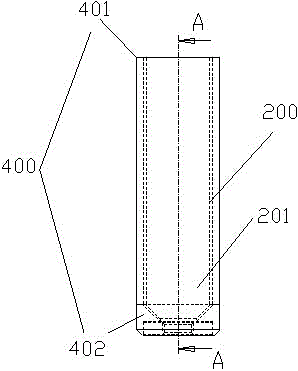

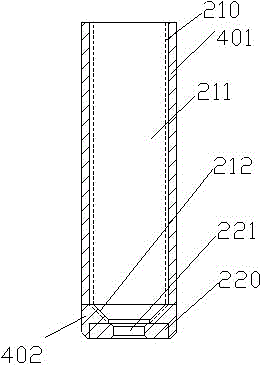

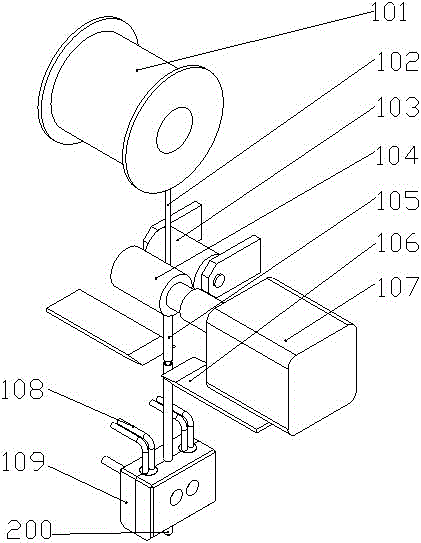

[0016] The invention provides an automatic soldering device with a structure such as image 3 As shown, it includes a soldering device for transferring a tin wire and a heating device for heating an electric soldering iron to melt the tin wire, as well as the aforementioned soldering iron tip 200, such as figure 2 As shown, the soldering iron tip 200 is connected to a heating device for sending out molten solder. A cutting knife 106 can be arranged between the tin feeding device and the heating device, such as image 3 As shown, it is used to cut the tin wire that needs to be melted. When used, it can be cut according to needs, and the supply of tin wire can be controlled more accurately than fusing solder wire.

[0017] Among them, the tin feeding device may specifically be a tin feeding wire idler 103 and a tin feeding wire driving wheel 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com