Automatic punch device of mold push rod

A technology of automatic punching and punching devices, applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve the problems of ineffective use of waste heat of electromagnetic induction coils, ineffective use of energy, and a large amount of manual input. , to achieve the effect of improving energy utilization, shortening processing cycle and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

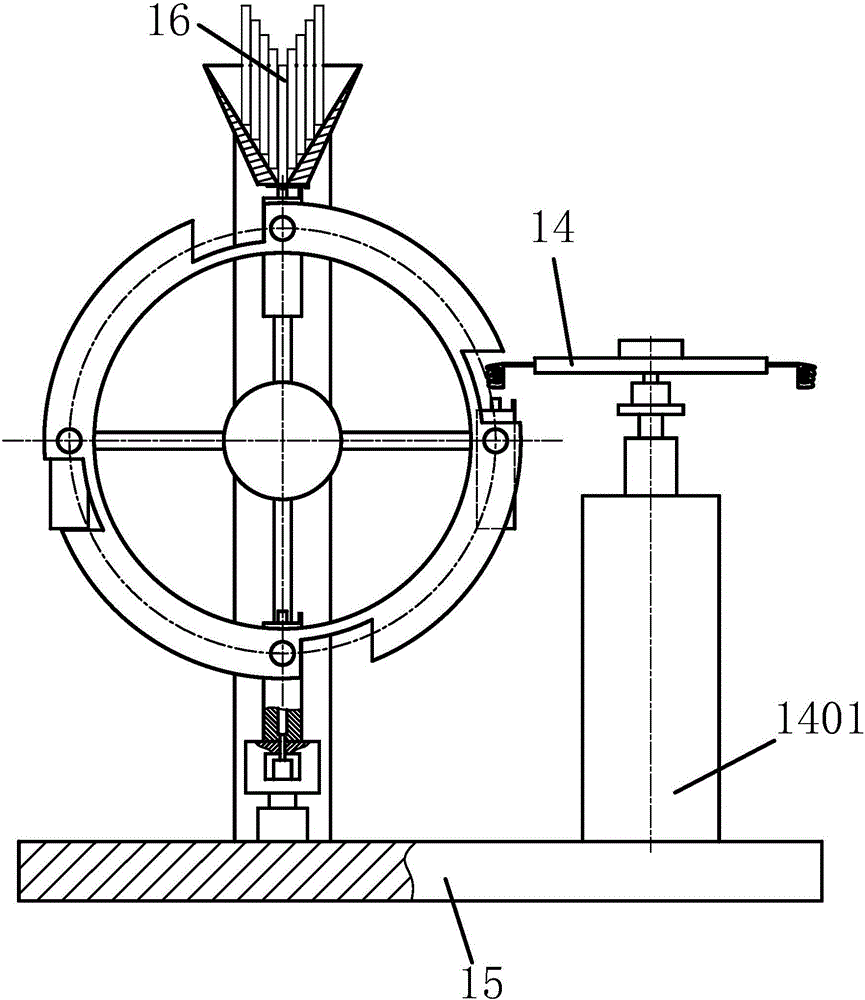

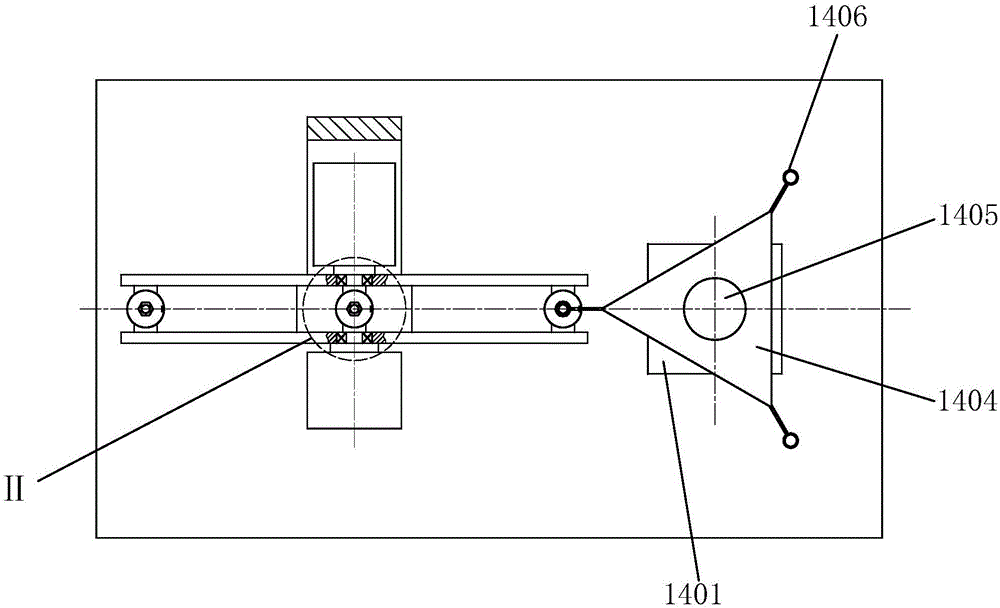

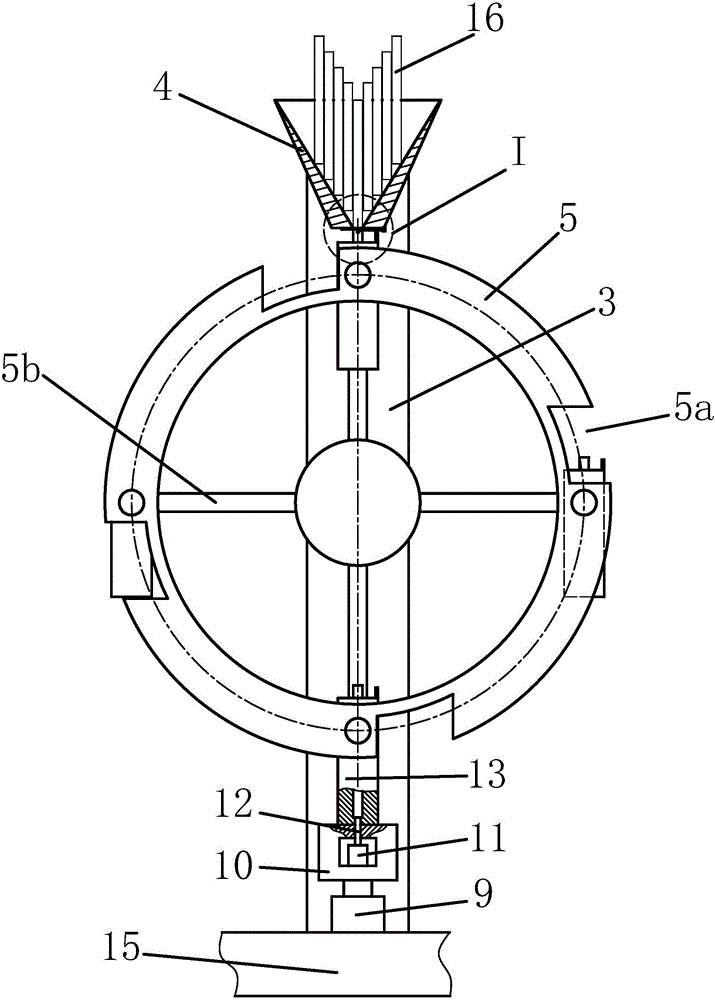

[0024] Such as Figure 1 to Figure 8 As shown, an automatic punching device for a mold push rod, including a base plate 15, a rotary heater 14, a machine table 1, a main drive motor 2, a vertical beam 3, a funnel-shaped storage box 4, and a circular feeder device, pad supporting device and punching device, the machine table 1 is installed on the left part of the upper end surface of the base plate 15, the rotary heater 14 is installed on the right part of the upper end face of the base plate 15, and the main drive motor 2 is horizontally fixed on the In the middle part of the upper end of the machine platform 1, the vertical suspension beam 3 is vertically installed on the upper end surface of the machine platform 1, the funnel-shaped material storage box 4 is fixed on the upper end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com