System for sorting blocky solid construction waste on basis of multiple detection modes

A technology for construction waste and detection methods, applied in sorting and other directions, can solve the problems of high cost, difficulty in separating different materials, and difficulty in fine sorting of construction waste, and achieve the effect of efficient sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

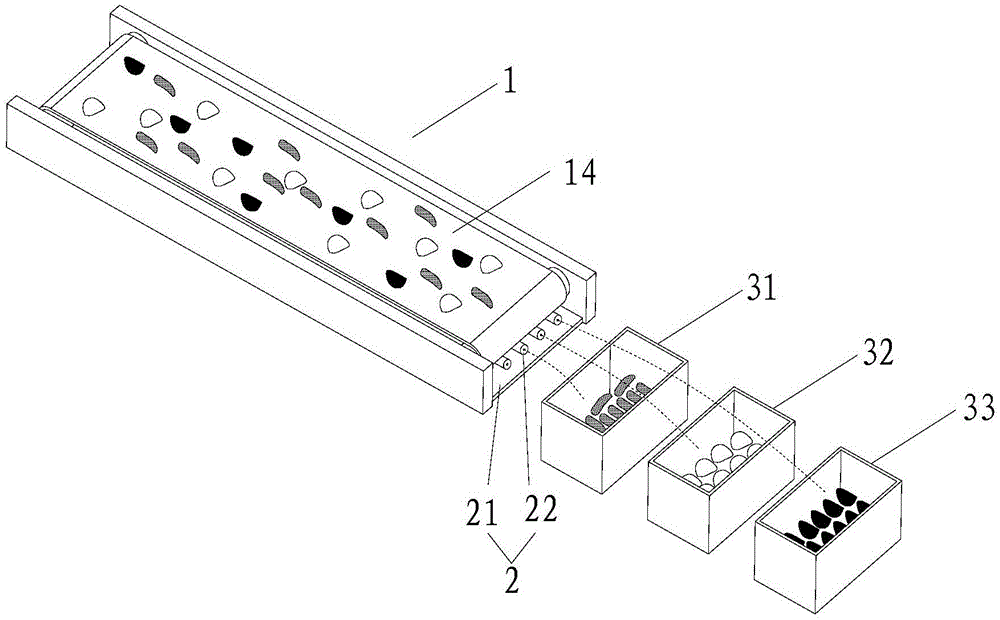

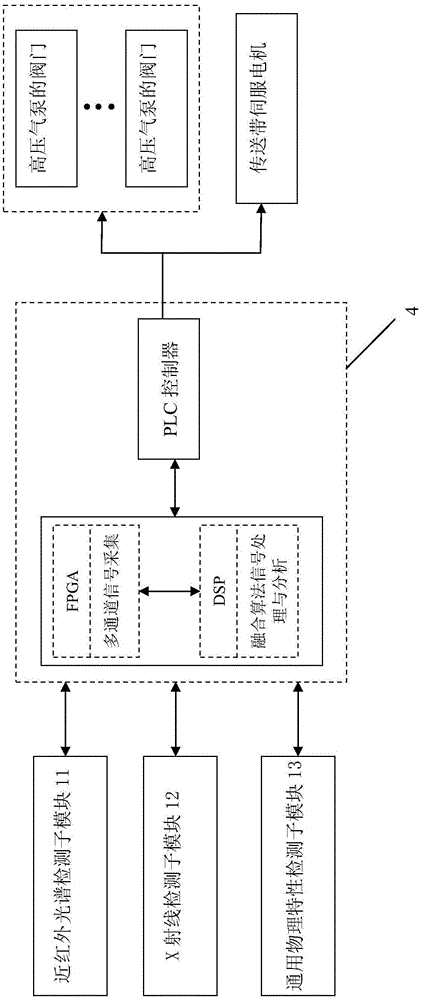

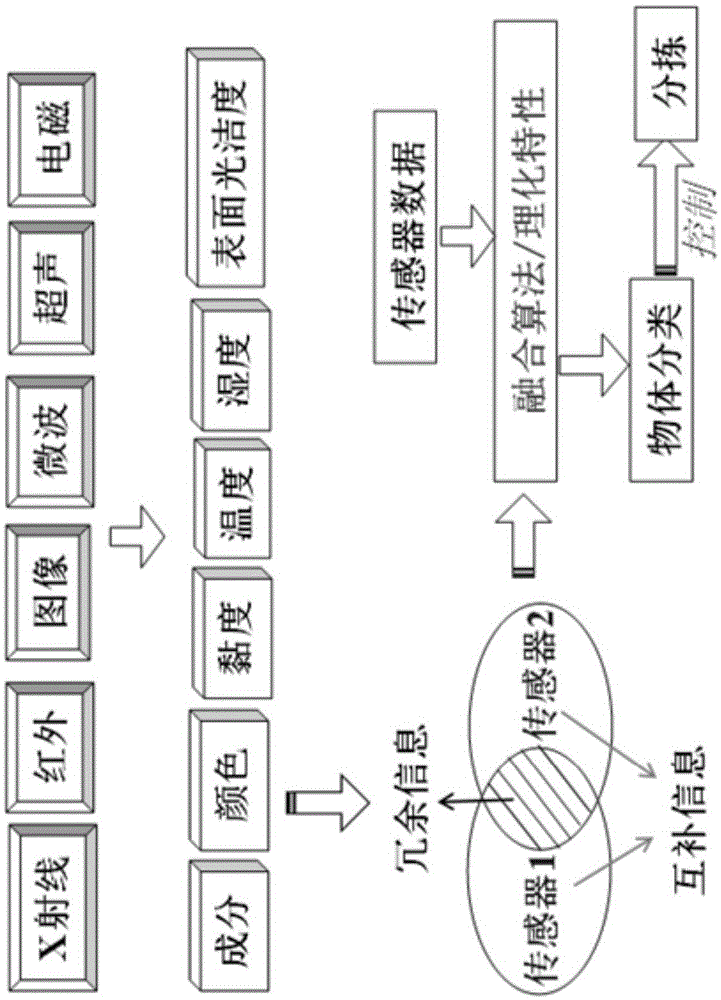

[0025] According to the source classification, construction waste can be divided into five types: land excavation, road excavation, old building demolition, building construction and building material production waste, mainly composed of muck, crushed stones, waste mortar, brick fragments, concrete Blocks, asphalt blocks, waste plastics, waste metals, waste bamboo and wood, etc. After the construction waste is crushed and a series of pre-sorting processes (including steps such as impurity removal, crushing, iron removal, and screening), plastic, paper, bamboo, wood, and metal are detected, and concrete, bricks, etc. can be obtained. , Stone and other massive solid construction waste, clean and dry this massive solid construction waste, concrete and bricks with a specific gravity between 1.3-1.6, stones with a specific gravity between 2.0-3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com