A method for purifying boiler flue gas

A boiler flue gas and boiler flue technology, applied in chemical instruments and methods, separation methods, lighting and heating equipment, etc., can solve secondary water pollution, affect environmental quality, poor dust removal efficiency, etc., to prevent secondary Water pollution, prevention of back channeling, good flue gas purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

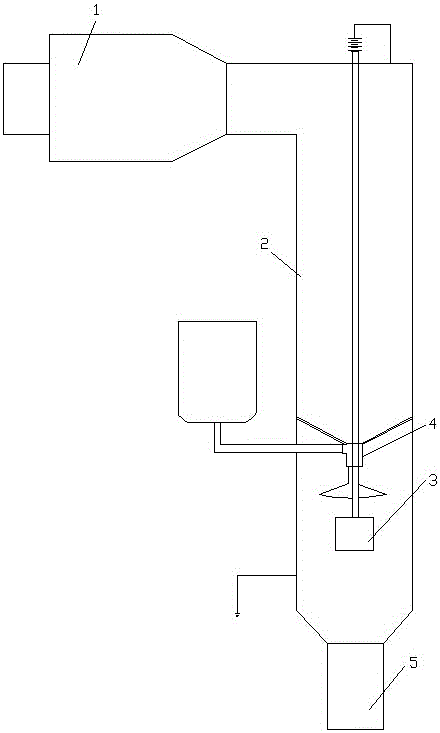

[0046] see figure 1 , a boiler flue gas purification method, comprising an electrostatic precipitator step and a desulfurization step, and also includes an evaporation drying step, the electrostatic precipitator step refers to introducing the flue gas in the boiler flue into an electrostatic precipitator 1, and the electrostatic precipitator 1 removes the smoke most of the dust in the gas; the desulfurization step refers to the mixing of the flue gas after the electrostatic precipitating step with the lye spray in the electric field 2 of the shaft, and the fine ash particles and sulfur dioxide in the flue gas gather under the force of the electric field and the lye spray , capture, coagulate and gather into small groups to stick on the electrode 3 of the shaft electric field 2; the evaporation and drying step means that the residual ash particles after the desulfurization step are washed into the evaporation drying box 5 by the water flow formed by the sprayer 4 , the evaporat...

Embodiment 2

[0049] see figure 1 , a boiler flue gas purification method, comprising an electrostatic precipitator step and a desulfurization step, and also includes an evaporation drying step, the electrostatic precipitator step refers to introducing the flue gas in the boiler flue into an electrostatic precipitator 1, and the electrostatic precipitator 1 removes the smoke most of the dust in the gas; the desulfurization step refers to the mixing of the flue gas after the electrostatic precipitating step with the lye spray in the electric field 2 of the shaft, and the fine ash particles and sulfur dioxide in the flue gas gather under the force of the electric field and the lye spray , capture, coagulate and gather into small groups to stick on the electrode 3 of the shaft electric field 2; the evaporation and drying step means that the residual ash particles after the desulfurization step are washed into the evaporation drying box 5 by the water flow formed by the sprayer 4 , the evaporat...

Embodiment 3

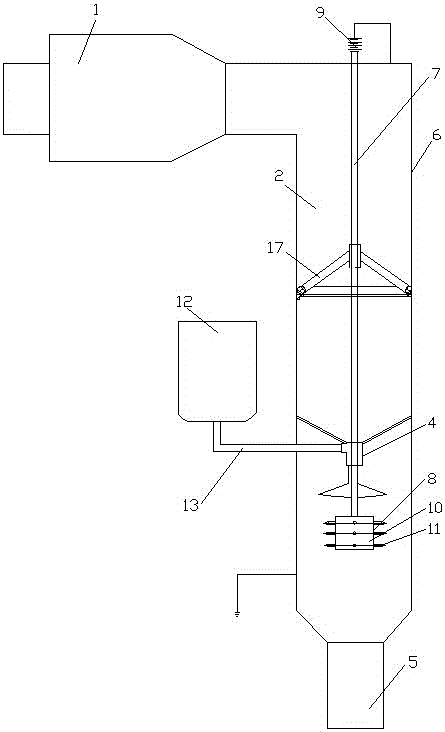

[0053] see figure 2 , a boiler flue gas purification method, comprising an electrostatic precipitator step and a desulfurization step, and also includes an evaporation drying step, the electrostatic precipitator step refers to introducing the flue gas in the boiler flue into an electrostatic precipitator 1, and the electrostatic precipitator 1 removes the smoke most of the dust in the gas; the desulfurization step refers to the mixing of the flue gas after the electrostatic precipitating step with the lye spray in the electric field 2 of the shaft, and the fine ash particles and sulfur dioxide in the flue gas gather under the force of the electric field and the lye spray , capture, coagulate and gather into small groups to stick on the electrode 3 of the shaft electric field 2; the evaporation and drying step means that the residual ash particles after the desulfurization step are washed into the evaporation drying box 5 by the water flow formed by the sprayer 4 , the evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com