Device and method for recovering and concentrating ortho-toluidine in ortho-toluidine wastewater by membrane extraction

A technology of o-toluidine and waste water, which is applied in the direction of liquid solution solvent extraction, total evaporation, purification/separation of amino compounds, etc., can solve the problems of inability to concentrate organic matter, large difference in removal rate and recovery rate, and large dosage. Fast quality, good for follow-up recycling, good for industrial production and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0040] A certain dye production wastewater: the concentration of o-toluidine is 2300mg / L, and the concentration of NaCl is 250g / L, which is high-salinity o-toluidine wastewater.

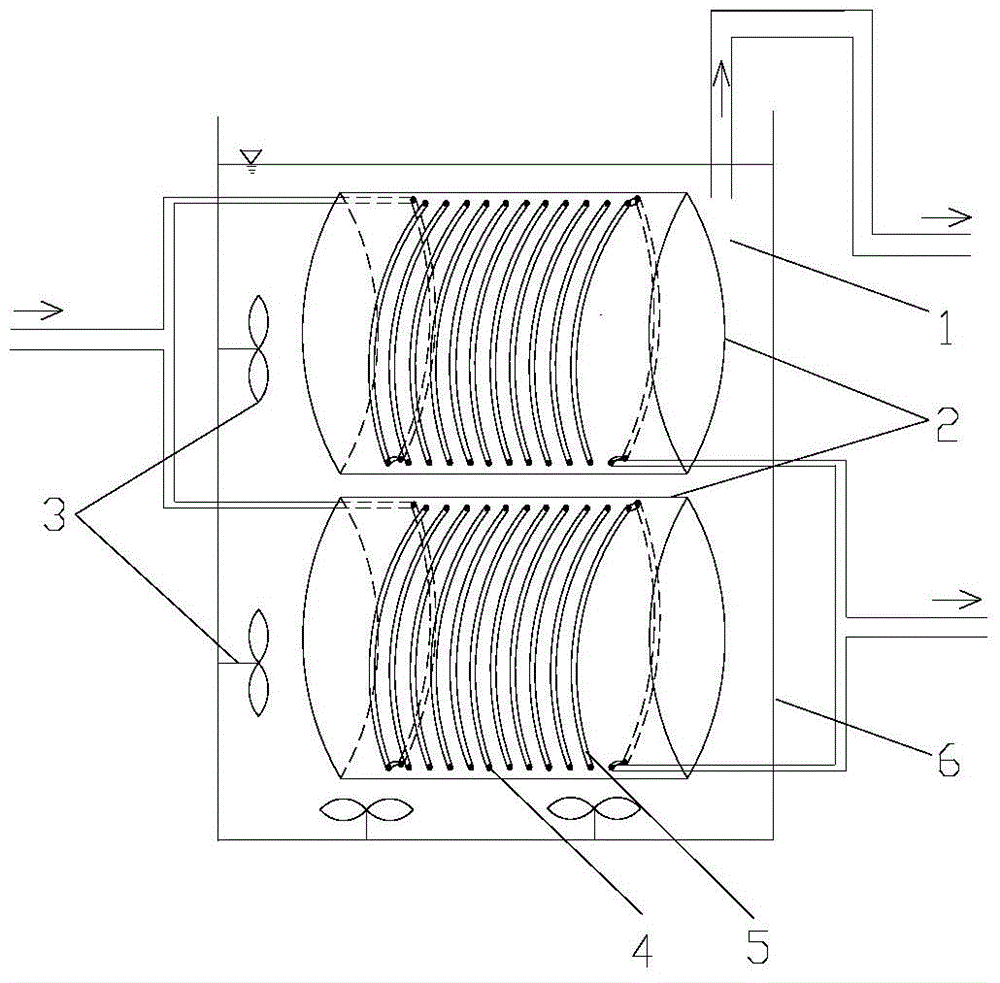

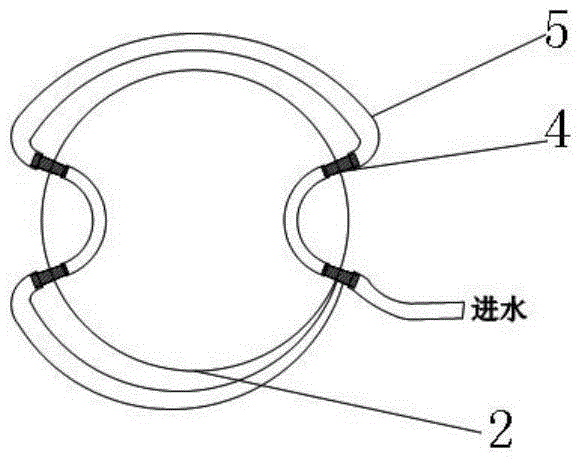

[0041] process such as image 3 shown. Step 1: Make a wound-type membrane reaction device: connect the silicone rubber tube 5 with a total length of 450-500m, an inner diameter of 5mm, and a thickness of 3mm to the support 2. The HCl extract solution is immersed in the reaction tank 6 to make a wound-type membrane reaction device. Step 2: Run the o-toluidine wastewater treatment system to treat high-salinity o-toluidine wastewater: the wastewater is first filtered to remove impurities in the water body and avoid blocking the silicone rubber extraction membrane tube; then the high-salinity wastewater is treated at a flow rate of 50L / h Enter the coiled silicone rubber extraction membrane tube, keep the pH value of the extract 1 after absorbing o-toluidine by continuously adding HCl solution to keep t...

example 2

[0043] O-toluidine production wastewater in a chemical factory: the wastewater is brownish red, with a pH value of 8-9, and the o-toluidine concentration is about 7500mg / L, which is high-concentration o-toluidine wastewater.

[0044] process such as Figure 4 shown. Step 1: Make a winding membrane reaction device: connect the silicone rubber tube 5 with a total length of 550-600m, an inner diameter of 3mm, and a thickness of 2mm to the support 2. The HCl extract 1 was submerged in the reaction tank 6, and two sets of reaction brackets were made to control the treatment effect due to the high concentration of wastewater. Step 2: Run the o-toluidine wastewater treatment system to treat high-concentration o-toluidine wastewater: the wastewater is first filtered to remove impurities in the water to avoid blocking the silicone rubber extraction membrane tube; then the high-concentration o-toluidine wastewater is treated with 60L / h The flow rate enters the coiled silicone rubber e...

example 3

[0055] A certain dye production wastewater: o-toluidine concentration is 4000mg / L, NaCl concentration is 300g / L, which is high salinity o-toluidine wastewater.

[0056] In this embodiment, a silicone rubber tube 5 with a total length of 520-550 m, an inner diameter of 4 mm, and a thickness of 2.5 mm is used to regularly connect to the support 2, and extract it together with the support 2 in the reaction tank 6 with HCl with a pH value less than or equal to 2. Liquid submersion, waste water enters the silicone rubber extraction membrane tube at a flow rate of 54L / h, the reaction temperature is 60°C, and other conditions are the same as in Example 1.

[0057] The content of o-toluidine in the wastewater at the outlet of the silicone rubber extraction membrane tube was measured, and the removal rate of o-toluidine was calculated to reach 98%. At the same time, o-toluidine was continuously concentrated and recovered in the acidic extraction solution, and the recovery rate reached 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com