End face coating fixture for stripe-geometry semiconductor laser and application thereof

A semiconductor and laser technology, applied in the field of bar-shaped semiconductor laser end-face coating fixtures, can solve the problems of bar warpage, difficult assembly, and rapid precision drop, reduce secondary or multiple damage, save processing material costs, prevent The effect of decreased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

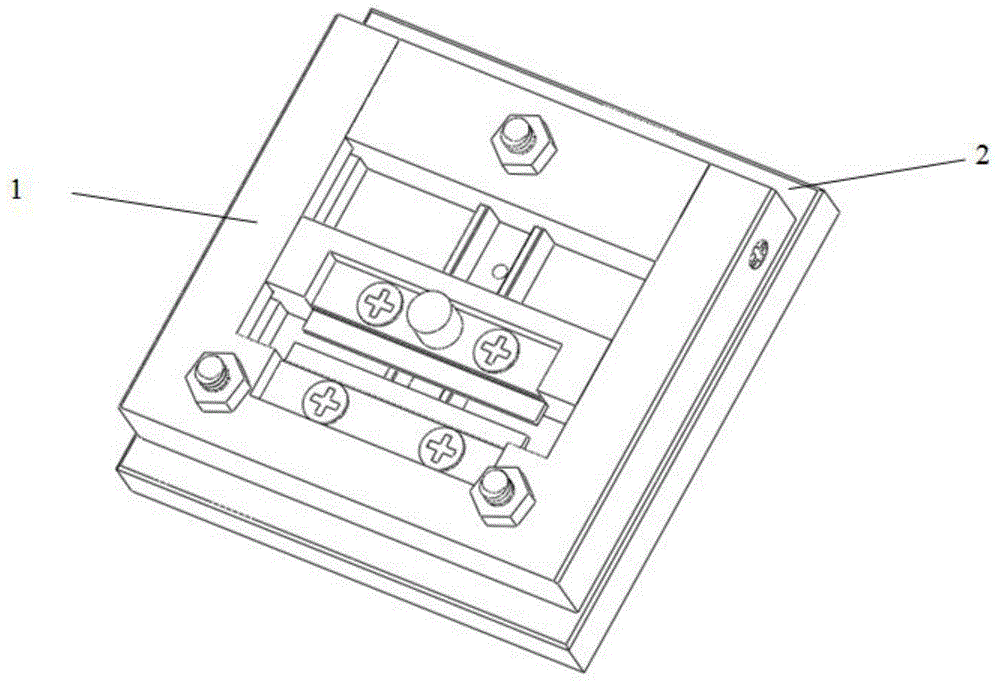

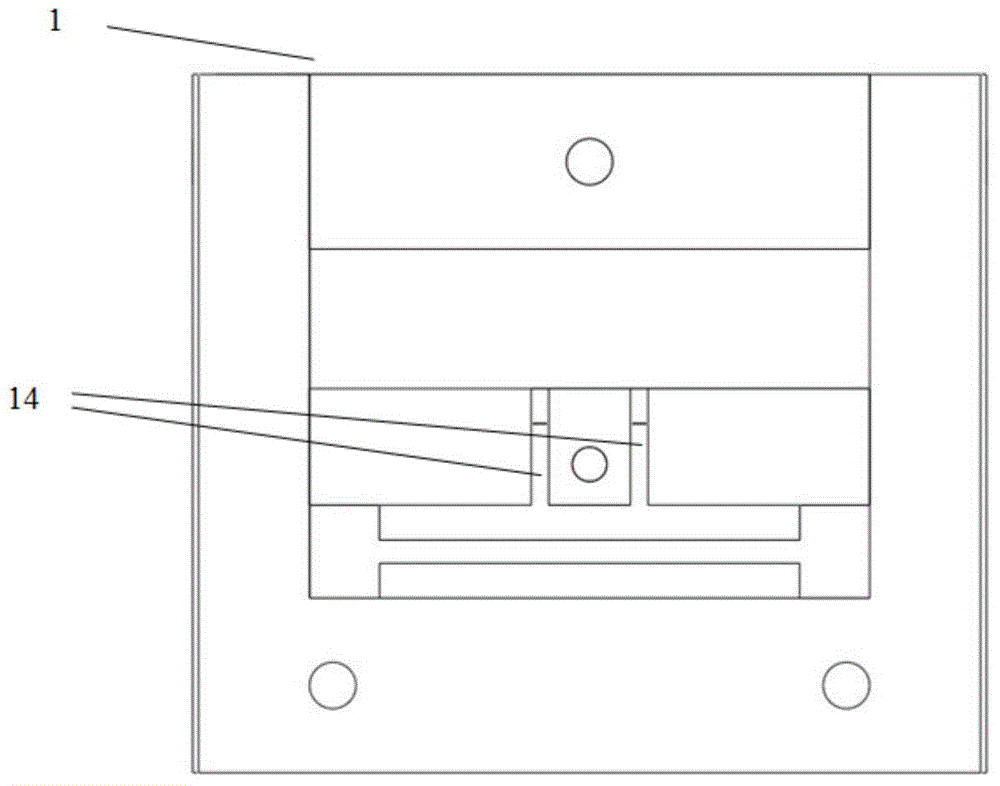

[0056] A strip-shaped semiconductor laser end face coating fixture, comprising a strip coating fixture 1 and an auxiliary loading tool 2, the strip coating fixture 1 includes a sliding part 5 and a combination frame, and the combination frame includes a U-shaped bottom frame 3 and an upper The horizontal frame 4 is provided with slideways 9 in the columns on both sides of the U-shaped bottom frame 3, and the two ends of the sliding part 5 are respectively convex embedded parts 10, and the slideway 9 and the convex shape The embedded part 10 fits together.

[0057] A detachable chin bar clamping end 6 is installed on the sliding part 5, and a detachable chin bar clamping end 7 is installed on the bottom of the U-shaped bottom frame 3, and the chin bar clamping end 7 is installed. The end 6 and the chin bar clamping end 7 are oppositely arranged. The clamping end 6 of the chin bar is fixed on the central concave platform of the sliding part 5 through gaskets and bolts; the clam...

Embodiment 2

[0059] A strip semiconductor laser end surface coating jig as described in Embodiment 1, the difference is that the sliding part 5 is connected to the auxiliary strip loading tool 2 through a limiting component.

Embodiment 3

[0061] A bar-shaped semiconductor laser end face coating fixture as described in Embodiment 1, the difference is that the combined frame is rectangular as a whole, and the upper horizontal frame 4 is embedded in the opening end of the U-shaped bottom frame 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com