High-flame-retardation, electricity-resistant and aging-resistant cable

A high flame-retardant and aging-resistant technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of reducing the service life of cables, difficult diffusion of space cables, local field strength distortion, etc., to prevent decomposition and improve DC breakdown strength and volume resistivity, the effect of gentle changes in field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

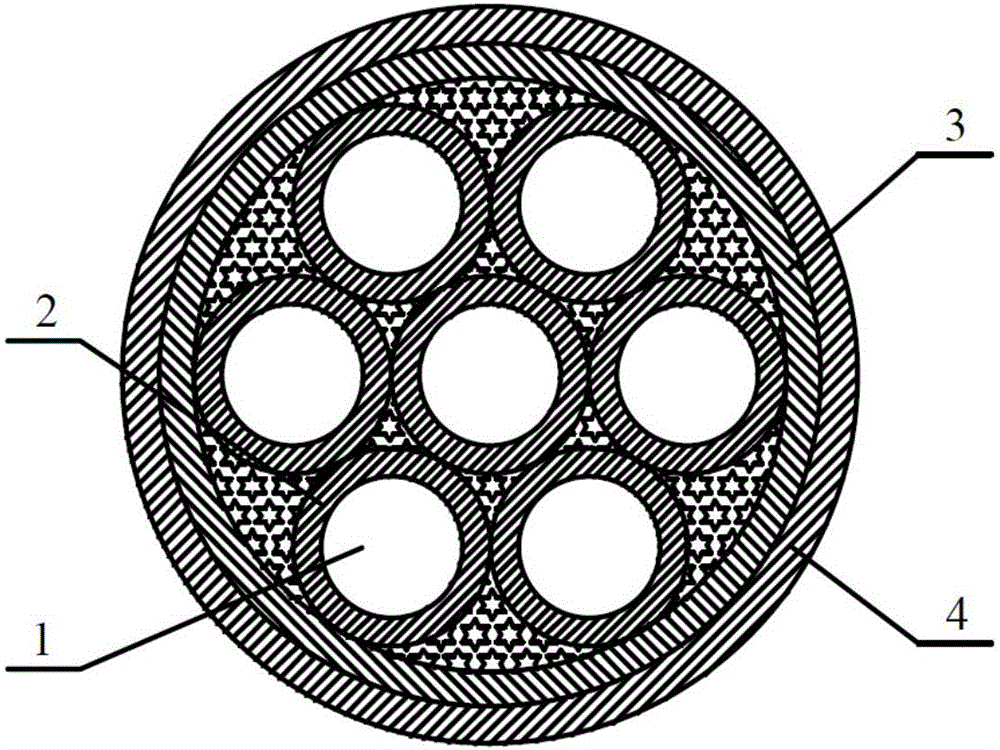

[0022] figure 1It is a structural schematic diagram of the high flame-retardant, electrical and aging-resistant cable described in the present invention, referring to figure 1 , a high flame-retardant, electrical, and aging-resistant cable proposed by the present invention, including a cable core, the cable core includes a conductor 1 located in the middle and an insulating layer 2 covering the outside of the conductor; an inner sheath layer 3 is provided outside the cable core , an outer sheath layer 4 is arranged outside the inner sheath layer 3, and the outer sheath layer 4 is made of a high flame-retardant modified polyethylene material, wherein the raw materials of the high flame-retardant modified polyethylene material include by weight The following components: 55 parts of low-density polyethylene, 45 parts of EPDM rubber, 45 parts of magnesium hydroxide particles, 15 parts of zinc borate, 5 parts of tricresyl phosphate, 50 parts of organically modified montmorillonite,...

Embodiment 2

[0024] refer to figure 1 , a high flame-retardant, electrical, and aging-resistant cable proposed by the present invention, including a cable core, the cable core includes a conductor 1 located in the middle and an insulating layer 2 covering the outside of the conductor; an inner sheath layer 3 is provided outside the cable core , an outer sheath layer 4 is arranged outside the inner sheath layer 3, and the outer sheath layer 4 is made of a high flame-retardant modified polyethylene material, wherein the raw materials of the high flame-retardant modified polyethylene material include by weight The following components: 80 parts of low-density polyethylene, 20 parts of EPDM rubber, 75 parts of magnesium hydroxide particles, 5 parts of zinc borate, 12 parts of tricresyl phosphate, 30 parts of organically modified montmorillonite, organically modified 40 parts of nano-magnesium oxide, 2 parts of modified nano-silica, 10 parts of ethylene-butyl acrylate copolymer, 3 parts of calc...

Embodiment 3

[0028] refer to figure 1 , a high flame-retardant, electrical, and aging-resistant cable proposed by the present invention, including a cable core, the cable core includes a conductor 1 located in the middle and an insulating layer 2 covering the outside of the conductor; an inner sheath layer 3 is provided outside the cable core , an outer sheath layer 4 is arranged outside the inner sheath layer 3, and the outer sheath layer 4 is made of a high flame-retardant modified polyethylene material, wherein the raw materials of the high flame-retardant modified polyethylene material include by weight The following components: 62 parts of low-density polyethylene, 40 parts of EPDM rubber, 63 parts of magnesium hydroxide particles, 7 parts of zinc borate, 10 parts of tricresyl phosphate, 37 parts of organically modified montmorillonite, organically modified 36 parts of nano-magnesium oxide, 3.8 parts of modified nano-silica, 9.3 parts of ethylene-butyl acrylate copolymer, 6 parts of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com