Nanowire vertical array based fluid viscosity detection device and detection method

A fluid viscosity and detection device technology, applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve the problems of low sensor measurement accuracy, increased equipment cost, small quality factor, etc., and achieve small size, easy movement, stability and reliability sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

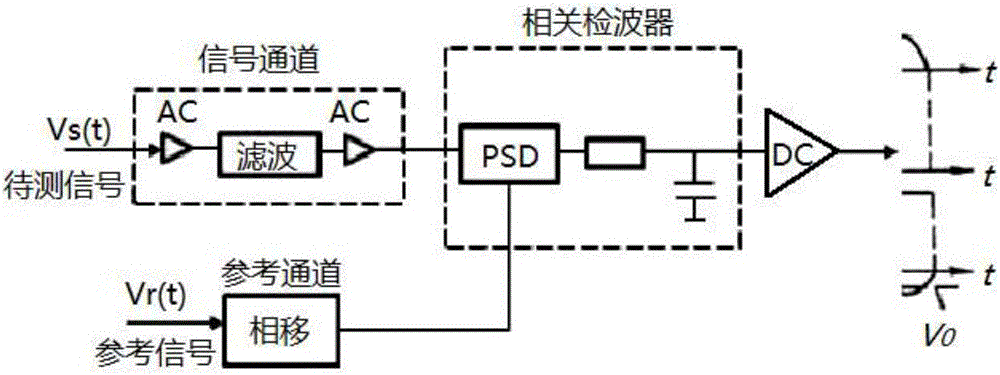

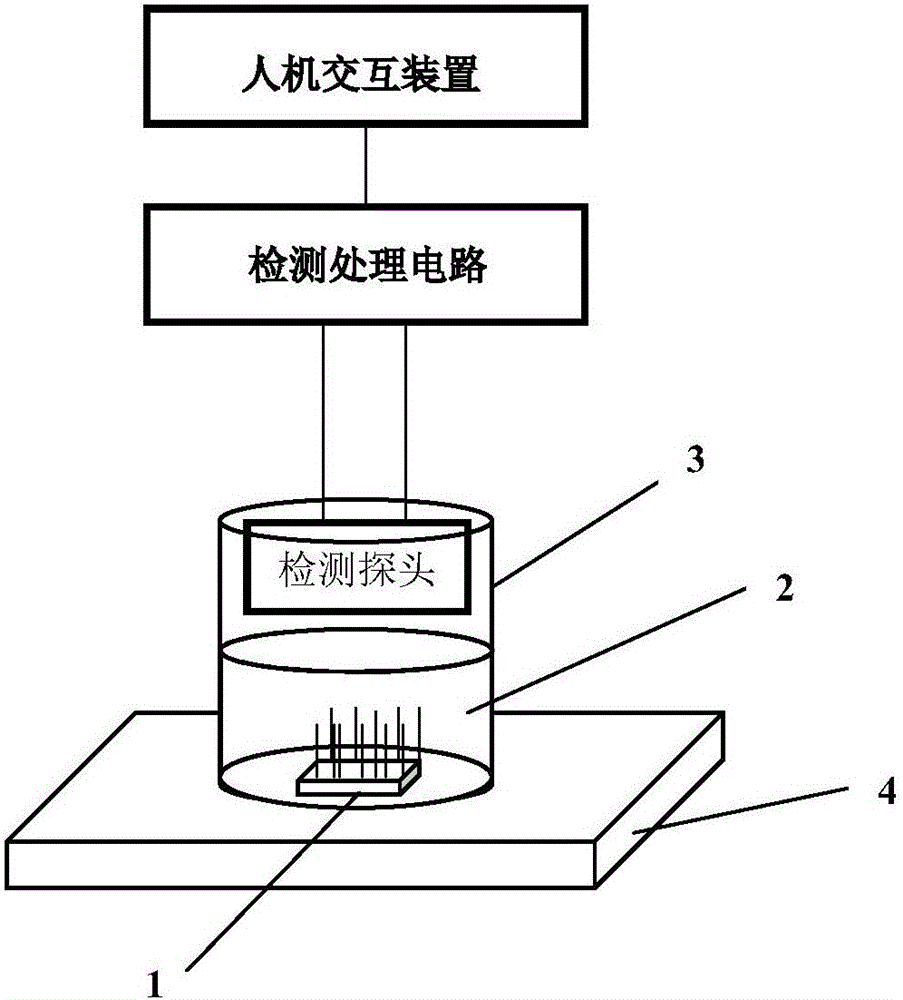

[0067] refer to figure 1 , a fluid viscosity detection device based on a nanowire vertical array, including a human-computer interaction device, a detection processing circuit, a detection probe including an excitation coil, and a microchip 1 made of a magnetic nanowire array 12, the detection probe is sequentially connected with the detection processing The circuit is connected with the human-computer interaction device, the microchip 1 is used to put into the fluid 2 to be tested, and the detection probe is used to provide the microchip 1 with an alternating magnetic field directly above the fluid 2 to be tested and detect the real-time vibration signal of the microchip 1 .

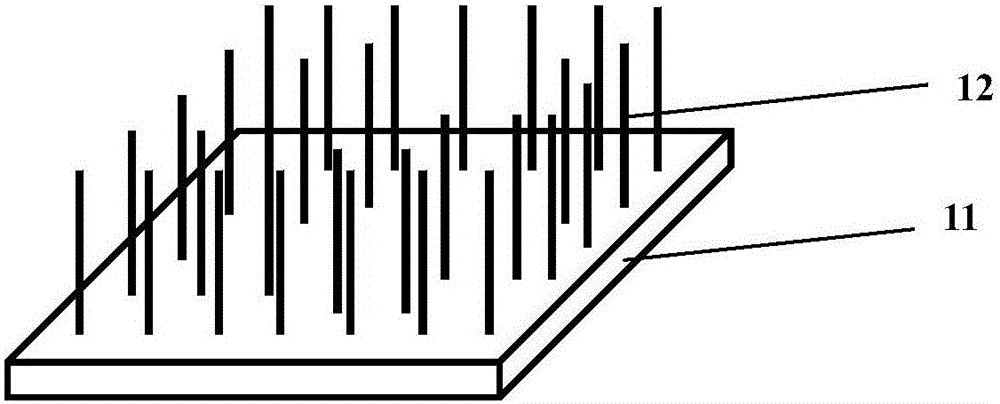

[0068] refer to figure 2 , the microchip 1 of this embodiment is made by preparing a vertical magnetic nanowire array 12 on a first substrate 11 by template electrochemical deposition method or solution gel method and other existing technologies. The material of the magnetic nanowire array 12 can be ...

Embodiment 2

[0086] The fluid viscosity detection method based on the nanowire vertical array using the fluid viscosity detection device of Embodiment 1 includes:

[0087] S1, immersing the microchip 1 made of the magnetic nanowire array in the fluid 2 to be tested;

[0088] S2. Place the detection probe on the top of the fluid 2 to be tested so that the detection probe is located directly above the microchip 1, adjust the lifting platform 4, and adjust the distance between the detection probe and the microchip 1 containing the magnetic nanowire array 12, Applying an alternating signal to the exciting coil of the detection probe, so that a mutual inductance coupling is formed between the detection probe and the microchip 1;

[0089] S3, using the detection probe to detect the real-time vibration signal of the microchip 1 and sending it to the detection processing circuit;

[0090] S4. After the real-time vibration signal of the microchip 1 is processed by the detection and processing circ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com