Rotary buckling machine driven and positioned by electric motor and buckling method thereof

A technology of electric motor and bending machine, which is applied in the field of rotary bending machine and its bending, and the pressing of bending blocks in wineries and vinegar factories. It can solve the problems of complex transmission of bending molds, unstable guidance, and unbalanced force of bending beams. To achieve the effect of improving pulp quality, avoiding bending deformation and avoiding mechanical failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be further described below.

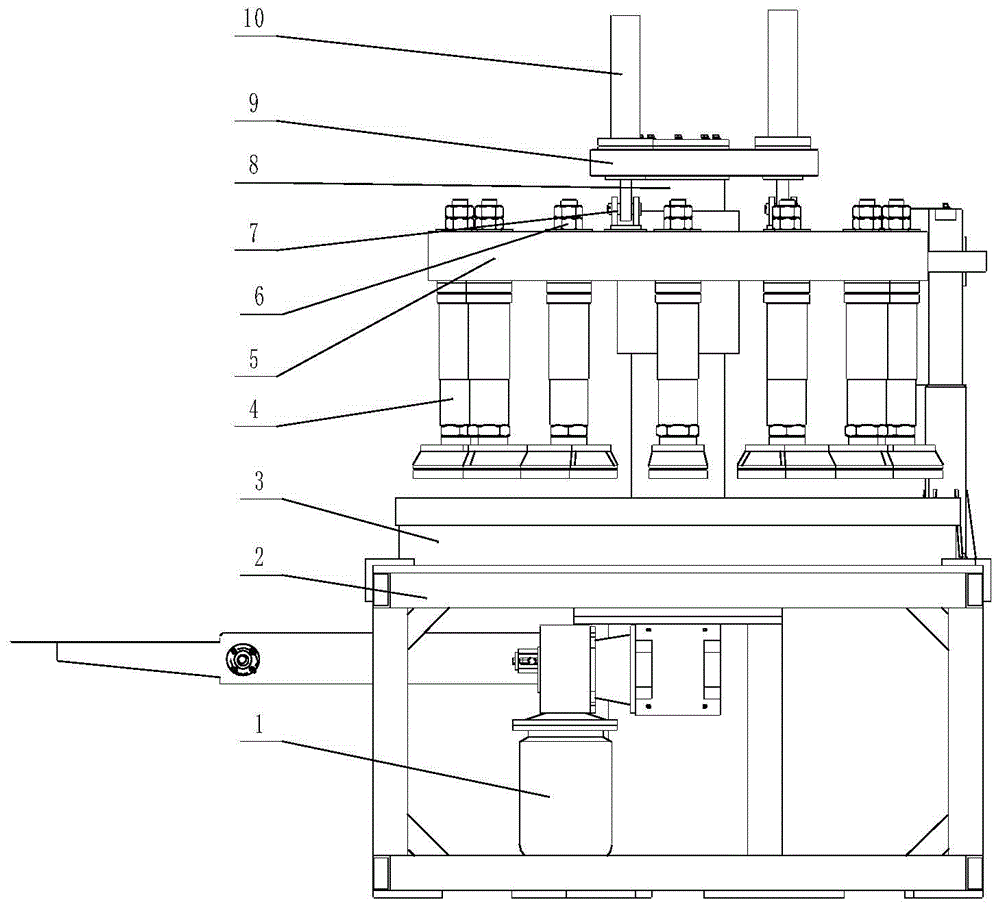

[0038]The main problem to be solved in the design of the bending machine is to accurately locate the position of the mold box of the bent material, to adjust the pressure and compression time during the compression process, to cooperate with the mold box of the bent material and the pressing hammer, and to prevent the beam from appearing during the movement. Stuck and larger vibration phenomenon.

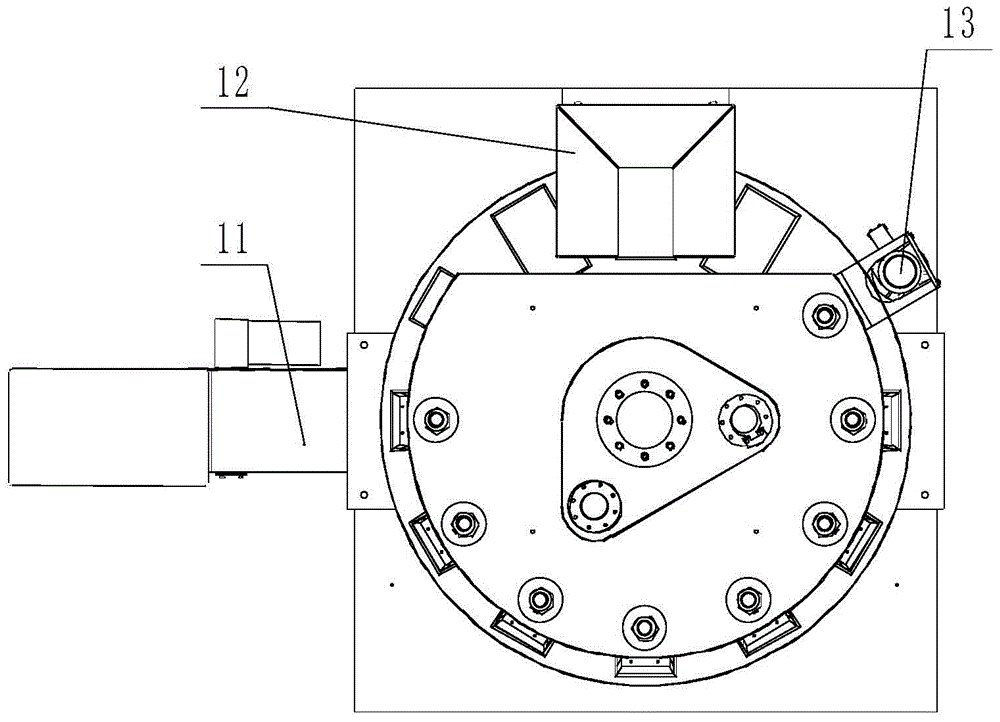

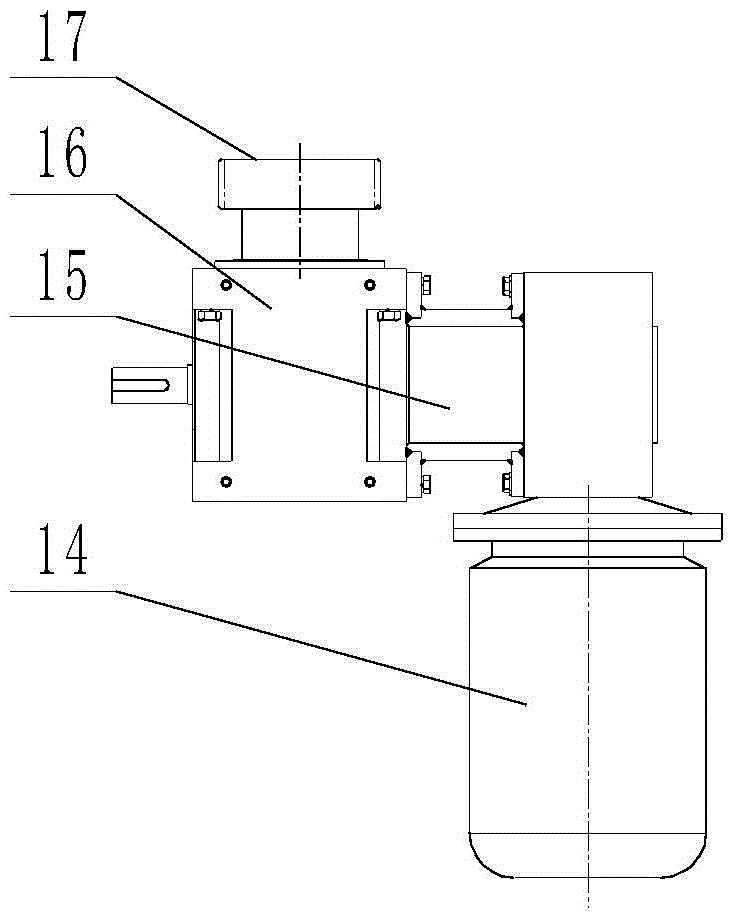

[0039] In order to overcome the problem of inaccurate positioning of the mold box of the existing buckling machine, the present invention specially adopts a high-speed precision cam intermittent divider for this problem, and its positioning accuracy is ±0.5'. The device can accurately position the turntable without additional auxiliary positioning devices. In order to control the buckling pressure more effectively, a cylindrical pressure sensor is specially designed to accurately ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com