Super-hydrophobic icing-preventing coating material and preparation method thereof

A coating material and anti-icing technology, applied in coatings, chemical instruments and methods, and other chemical processes, can solve problems such as poor coagulation ability, achieve low adhesion, prevent icing, and high hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

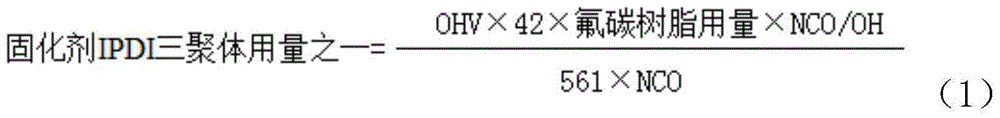

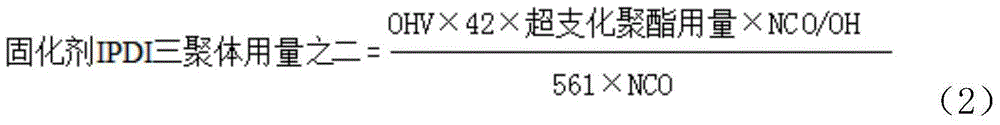

[0020] A superhydrophobic anti-icing coating material, comprising the following raw materials: 40g fluorocarbon resin, 0.4g hyperbranched resin, 24gSiO 2 , 8gTiO 2 , 25g xylene, 25g butyl acetate, 1.224g coupling agent KH-602, 1.836g defoamer, 0.808g dispersant, 1.224g wetting agent, and 0.437g isophorone diisocyanate (IPDI) trimerization body;

[0021] The specific preparation method is: dissolve 40g fluorocarbon resin and 0.4g self-made hyperbranched resin in 25g xylene and 25g butyl acetate solvent, add 1.224g coupling agent KH-602 after mechanical stirring for half an hour, and continue stirring for 10 minutes , then add 0.808g dispersant 4060, 1.224g wetting agent 3034, 1.836g defoamer 2022, and mechanically stir for 3 hours. Then add 24g of gas phase SiO 2 and 8g TiO 2 . After mechanical stirring for 5 hours, the superhydrophobic anti-icing coating was obtained by grinding in a conical mill. Weigh 10 g of paint, add 0.437 g of isophorone diisocyanate (IPDI) trimer,...

Embodiment 2

[0023] A superhydrophobic anti-icing coating material, comprising the following raw materials: 45g fluorocarbon resin, 0.45g hyperbranched resin, 28gSiO 2 , 8gTiO 2 , 36g xylene, 36g butyl acetate, 1.535g coupling agent KH-602, 2.302g defoamer, 0.72g dispersant, 1.535g wetting agent, and 0.392g isophorone diisocyanate (IPDI) trimer body;

[0024] The specific preparation method is: dissolve 45g fluorocarbon resin and 0.45g self-made hyperbranched resin in 36g xylene and 36g butyl acetate solvent, add 1.535g coupling agent KH-602 after mechanical stirring for half an hour, and continue stirring for 10 minutes , then add 0.72g dispersant 4060, 1.535g wetting agent 3034, 2.302g defoamer 2022, and mechanically stir for 3 hours. Then add 28g of gas phase SiO 2 and 8gTiO 2 . After mechanical stirring for 5 hours, the superhydrophobic anti-icing coating was obtained by grinding in a conical mill. Weigh 10 g of paint, add 0.392 g of isophorone diisocyanate (IPDI) trimer, and mix...

Embodiment 3

[0026] A superhydrophobic anti-icing coating material, comprising the following raw materials: 50g fluorocarbon resin, 0.5g hyperbranched resin, 32gSiO 2 , 8gTiO 2 , 40g xylene, 40g butyl acetate, 1.705g coupling agent KH-602, 2.558g defoamer, 1.01g dispersant, 1.705g wetting agent, and 0.392g isophorone diisocyanate (IPDI) trimer body;

[0027] Dissolve 50g of fluorocarbon resin and 0.5g of self-made hyperbranched resin in 40g of xylene and 40g of butyl acetate solvent, stir mechanically for half an hour, add 1.705g of coupling agent KH-602, continue stirring for 10 minutes, and then add 1.01g Dispersant 4060, 1.705g wetting agent 3034, 2.558g defoamer 2022, mechanically stirred for 3 hours. Then add 32g of gas phase SiO 2 and 8gTiO 2 . After mechanical stirring for 5 hours, the superhydrophobic anti-icing coating was obtained by grinding in a conical mill. Weigh 10 g of paint, add 0.392 g of isophorone diisocyanate (IPDI) trimer, and mix well. The paint was sprayed on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com