Sludge acidification fermentation treatment system

A technology of sludge acidification and treatment system, applied in the field of sludge acidification fermentation treatment system, can solve problems such as process pollution and energy consumption, and achieve the effects of improving efficiency, improving utilization efficiency and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below through specific examples.

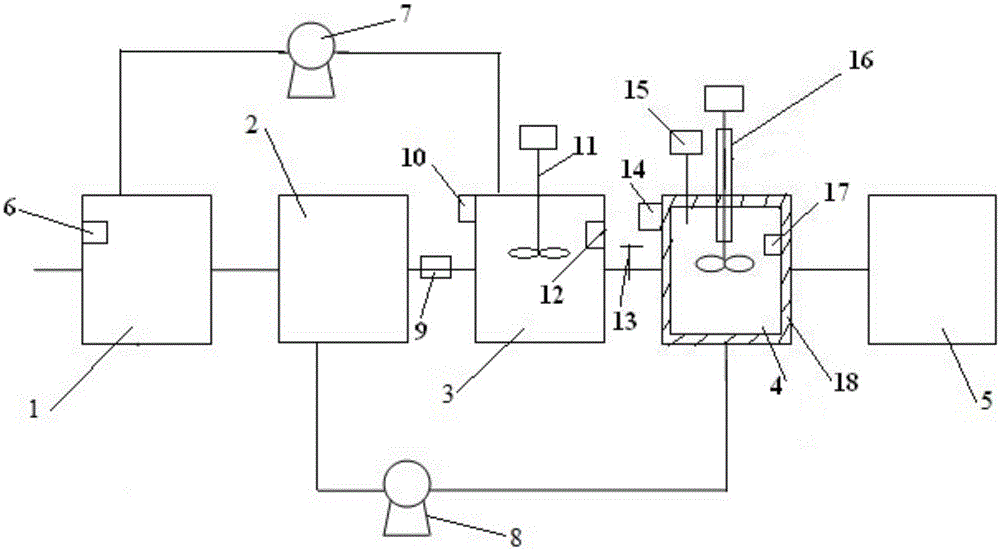

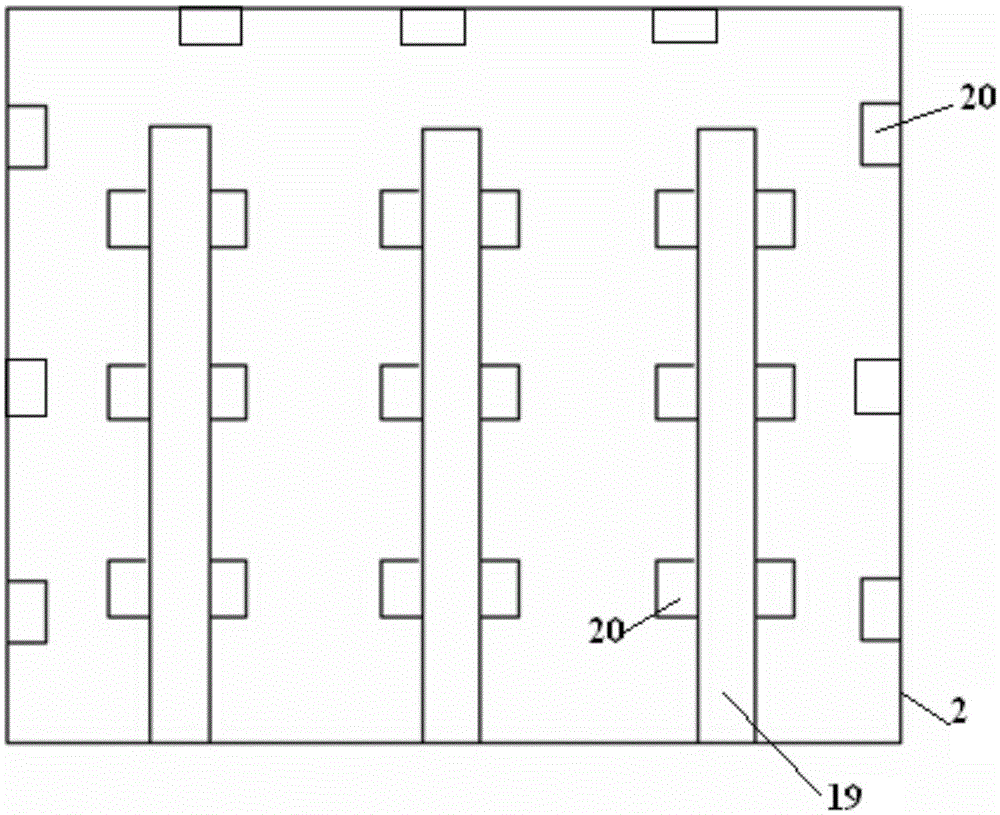

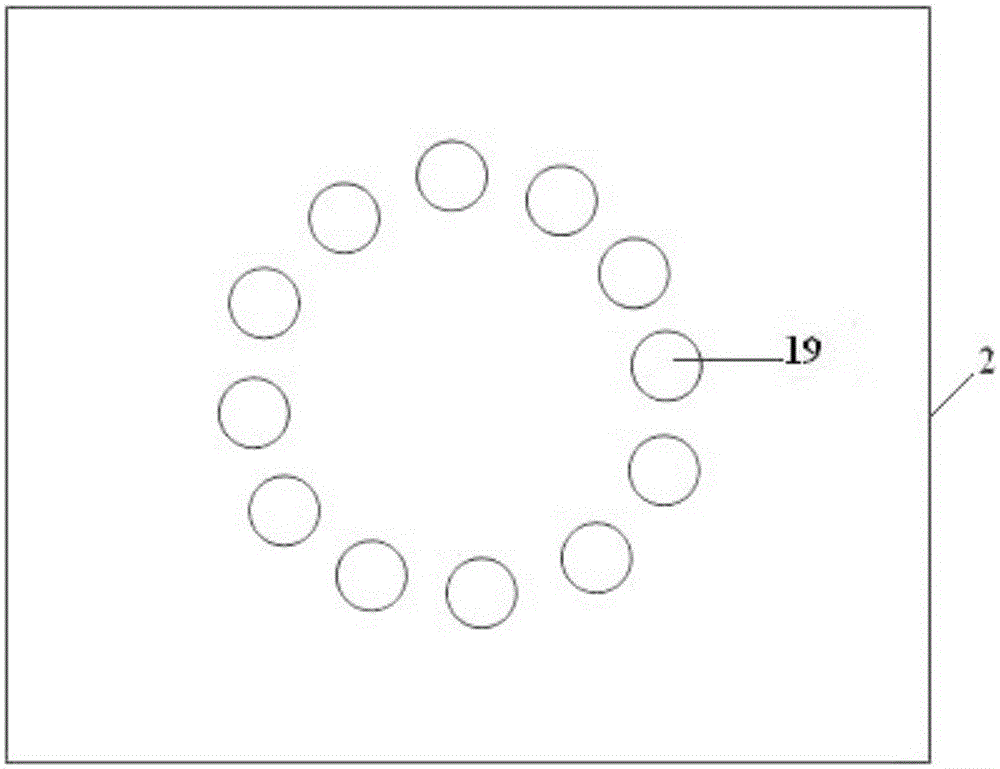

[0021] Such as figure 1 and figure 2 As shown, 1 is the acidification pretreatment tank, 2 is the ultrasonic treatment tank, 3 is the acidification hydrolysis tank, 4 is the facultative fermentation tank, 5 is the dehydration tank, 6 is the pH adjustment device, 7 is the first reflux pump, and 8 is the second Two reflux pumps, 9 is a flow monitoring device, 10 is a first temperature sensor, 11 is a stirring device, 12 is a pH monitoring device, 13 is a flow regulating valve, 14 is a second temperature sensor, 15 is a biogas collection device, 16 is a feeding Oxygen stirring device, 17 is an oxygen content monitoring device, 18 is an insulating layer, 19 is a column partition, and 20 is an ultrasonic generator.

[0022] Sludge acidification fermentation treatment system, including acidification pretreatment tank, ultrasonic treatment tank, acidification hydrol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com